9

MAINTENANCE

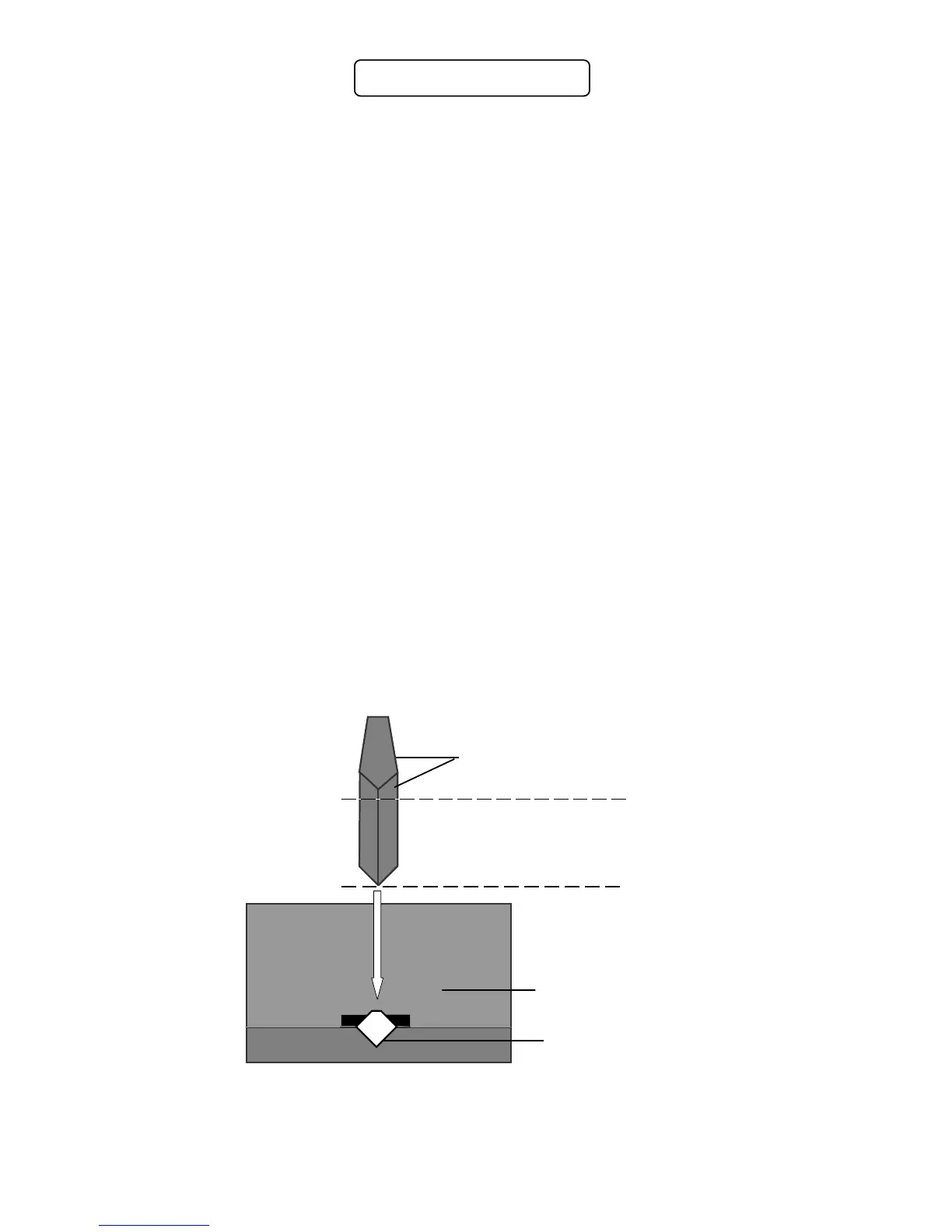

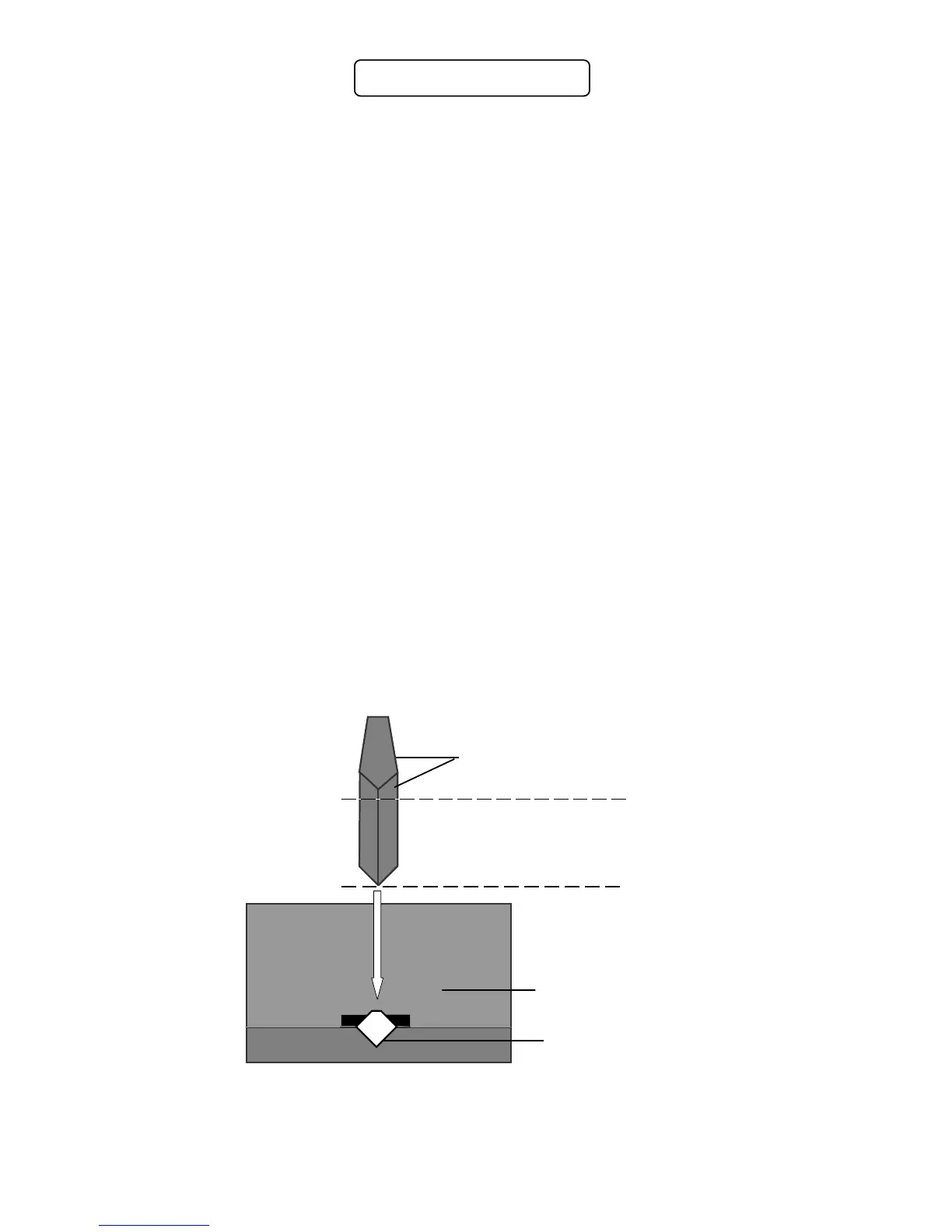

6mm MAXIMUM ( 1/4’’ )

WEDGE REMOVING TOOL

DISTRIBUTOR

( BLOCK H )

WEDGE EXIT

1) LUBRICATION

Periodically, remove the wedge distributor (Fig 1, block H) and clean it (by air gun) without dis-

mounting it.

It is recommended to lubricate the hammer (driver blade) periodically. To do so, remove the wedge

distributor (blockH) and put a small quantity of grease in the bottom hole of the wedge distributor.

The hammer will be lubricated every time it crosses the wedge distributor.

2) CLEARING OF A WEDGE STUCK IN THE WEDGE DISTRIBUTOR

If you push the foot pedal half way and release, a wedge may be half engaged in the wedge

distributor. In this case,

- Try to remove the cartridge that is in position. If it resists, use the wedge removal tool to push

down the wedge back in the cartridge.

- Pay attention not to make penetrate the tool more than 6mm (¼”) into the wedge distributor.

It is important not to leave a wedge half engaged in the wedge distributor, as it may cause the

insertion of two wedges when you join the next corner or may cause the jamming of the

hammer (the driver blade) in the wedge distributor.

- In case of the hammer (driver blade) jamming with a wedge in the wedge distributor, see the fol-

lowing section (3).

Loading...

Loading...