3

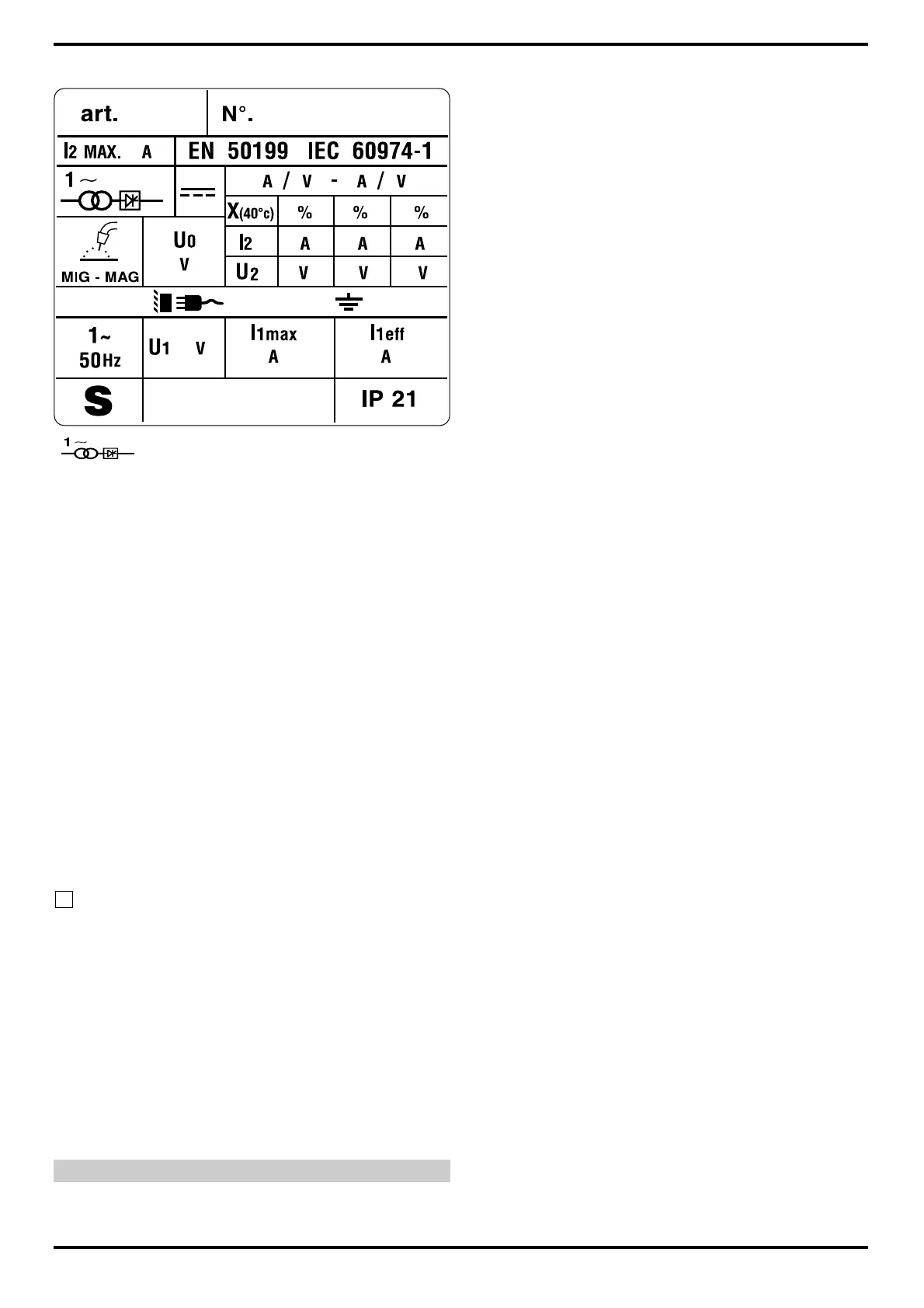

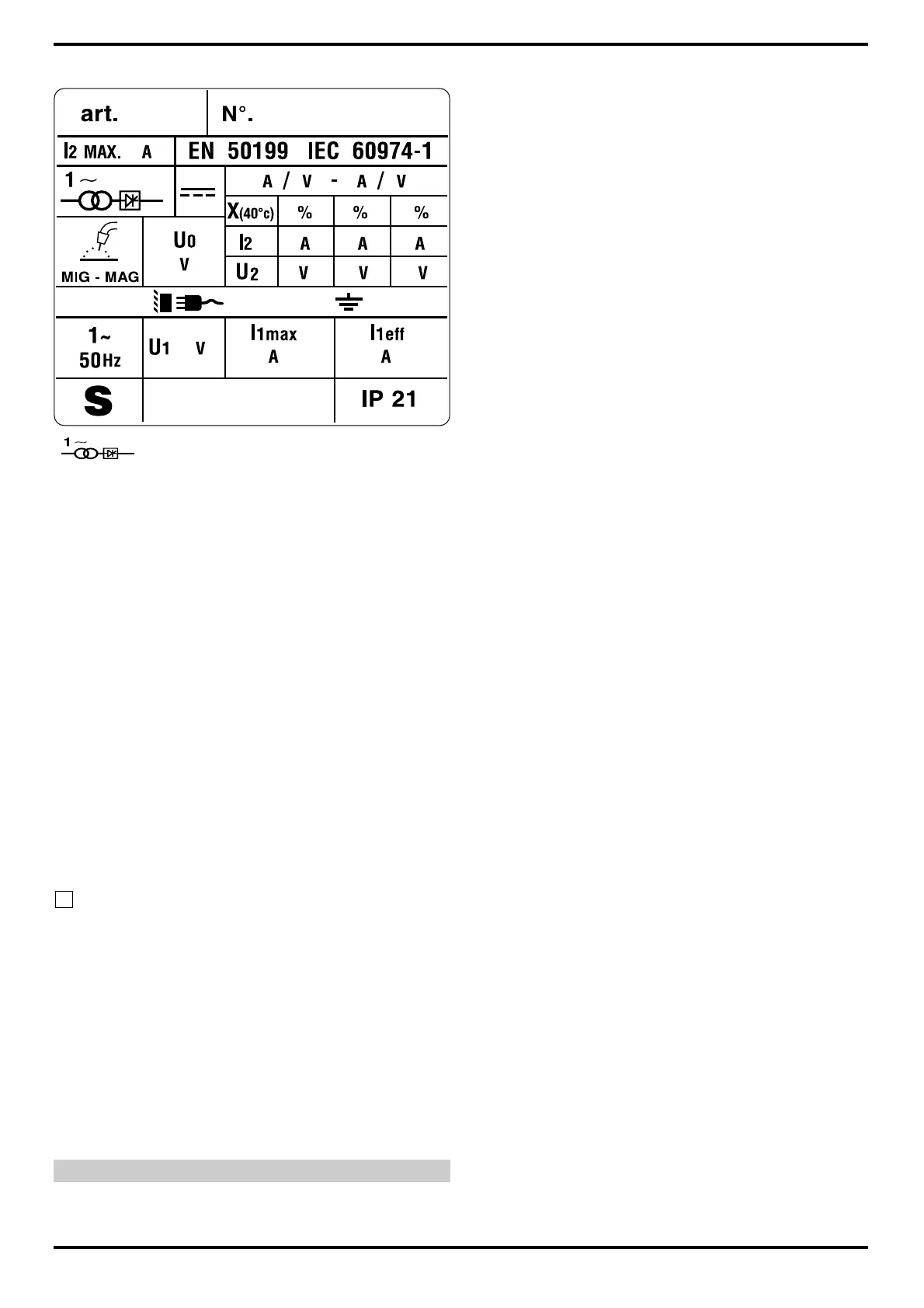

single-phase transformer-rectifier.

MIG/MAG. Suitable for continuous electrode welding.

I2 MAX Unconventional welding current.

The values represent the maximum levels

attainable in welding.

U0. Secondary open-circuit voltage.

X. Duty cycle percentage.

The duty cycle expresses the percentage

of 10 minutes during which the welding

machine may run at a certain current

without overheating.

I2. Welding current

U2. Secondary voltage with welding current

I2.

U1. Rated supply voltage

1~ 50Hz 50-Hz single-phase power supply.

I1 max. This is the maximum value of the rated

supply current.

I1 eff. This is the maximum value of the effective

input current, considering the duty cycle.

IP21 Protection rating for the housing.

Grade 1 as the second digit means that

this equipment is suitable for use out-

doors in the rain.

Suitable for use in high-risk environ-

ments.

NOTES:The welding machine has also been designed for use

in environments with a pollution rating of 3. (See IEC 664).

3.3 DESCRIPTION OF PROTECTION

This device is protected by a normally closed thermostat

on the power transformer.

When the thermostat is tripped the machine stops wel-

ding, while the motor-driven fan continues to run and the

yellow LED lights.

After it has been tripped, wait a few minutes to allow the

generator to cool down.

4 INSTALLATION

The machine must be installed by skilled personnel. All

S

connections must be made in compliance with current

regulations and in full respect of safety laws.

Make sure that the wire diameter corresponds to the one

indicated on the roller, and mount the wire reel. Make sure

that the welding wire passes through the groove in the

small roller 5.

Before connecting the power cable 29, make sure that the

power voltage corresponds to that of the welding machine,

then: a) for permanent connection to the power mains

without a plug, you must insert a main switch

having a suitable capacity in compliance with the

rated specifications.

b) for a plug-socket connection, use a plug having

a suitable capacity in compliance with the rated

specifications. In this case the plug must be used

to completely disconnect the machine from the

mains, after setting the switch 43 to “O” (off).

The yellow-green wire must be connected to the earth ter-

minal.

Connect the earth clamp 20 to the part to be welded.

The welding circuit must not be deliberately placed in

direct or indirect contact with the protection wire except in

the workpiece.

If the workpiece is deliberately grounded using the protec-

tion wire, the connection must be as direct as possible,

using a wire at least as large as the welding current return

wire, and connected to the workpiece at the same point as

the return wire, using the return wire clamp or a second

grounding clamp placed next to it.

All precautions must be taken to avoid stray welding cur-

rents.

Turn the machine on using the switch 43.

Remove the tapered gas tip by turning it clockwise.

Unscrew the contact tip.

Do not press the torch trigger until you have read the

instructions carefully.

It is important to make sure the machine is turned off whe-

never changing the wire reel and wire roller, to prevent the

wire feed motor from starting accidentally.

Press the torch trigger and release it only when the wel-

ding wire comes out.

Welding wire can cause puncture wounds.

Never aim the torch at parts of the body, other people or

metals when loading the welding wire.

Screw the contact tip back on, making sure that the hole

diameter corresponds to the wire used.

Slide the tapered gas welding tip on, always turning

clockwise.

4.1 CONNECTING THE GAS HOSE

l The gas cylinder must be equipped with a pressure

reducer and flow meter.

l If the cylinder is placed on the cylinder holder of the

machine, it must be held in place by the chain provided

and be of an appropriate size to avoid jeopardizing the

stability of the machine.

l Connect the gas hose leaving the back of the machine

to the pressure reducer only after the cylinder is in place.

l Open the gas cylinder and set the flow meter to approxi-

mately 8-10 lt./min.

CAUTION: Make sure the gas used is compatible with the

material to be welded.

Loading...

Loading...