4

4.2 GENERAL NOTES

Before using this welding machine, carefully read the

regulations CEI 26/9 or CENELEC HD 407 and CEI 26/11

or CENELEC HD 433. Also make sure that the insulation

on cables, torch and earth cable is intact.

5 WELDING

5.1 WELDING MILD STEEL

Either 75% ARGON + 25% CO2 or 100% CO2 may be

used for welding mild steel.

Select the welding current by means of the rotary switch 40.

Move the torch near the welding point and press the trigger.

Adjust the potentiometerl knob until the welding is done

with a constant, continuous noise.

If the speed is too fast, the wire tends to stick to the piece

and cause the torch to skip; if the speed is too low, the

wire melts in spaced drops or the arc does not remain lit.

When you have finished welding, turn off the machine and

close the gas cylinder.

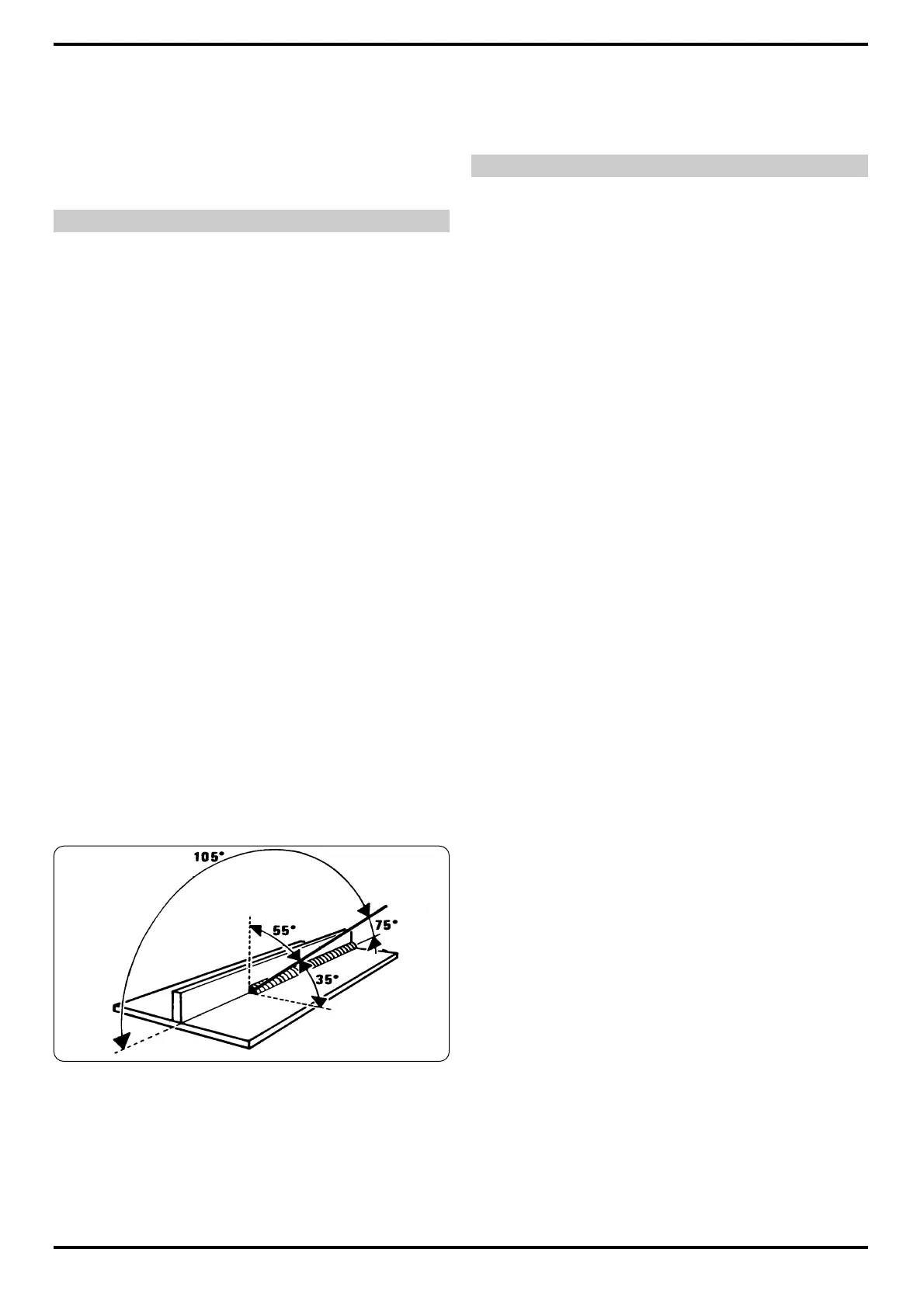

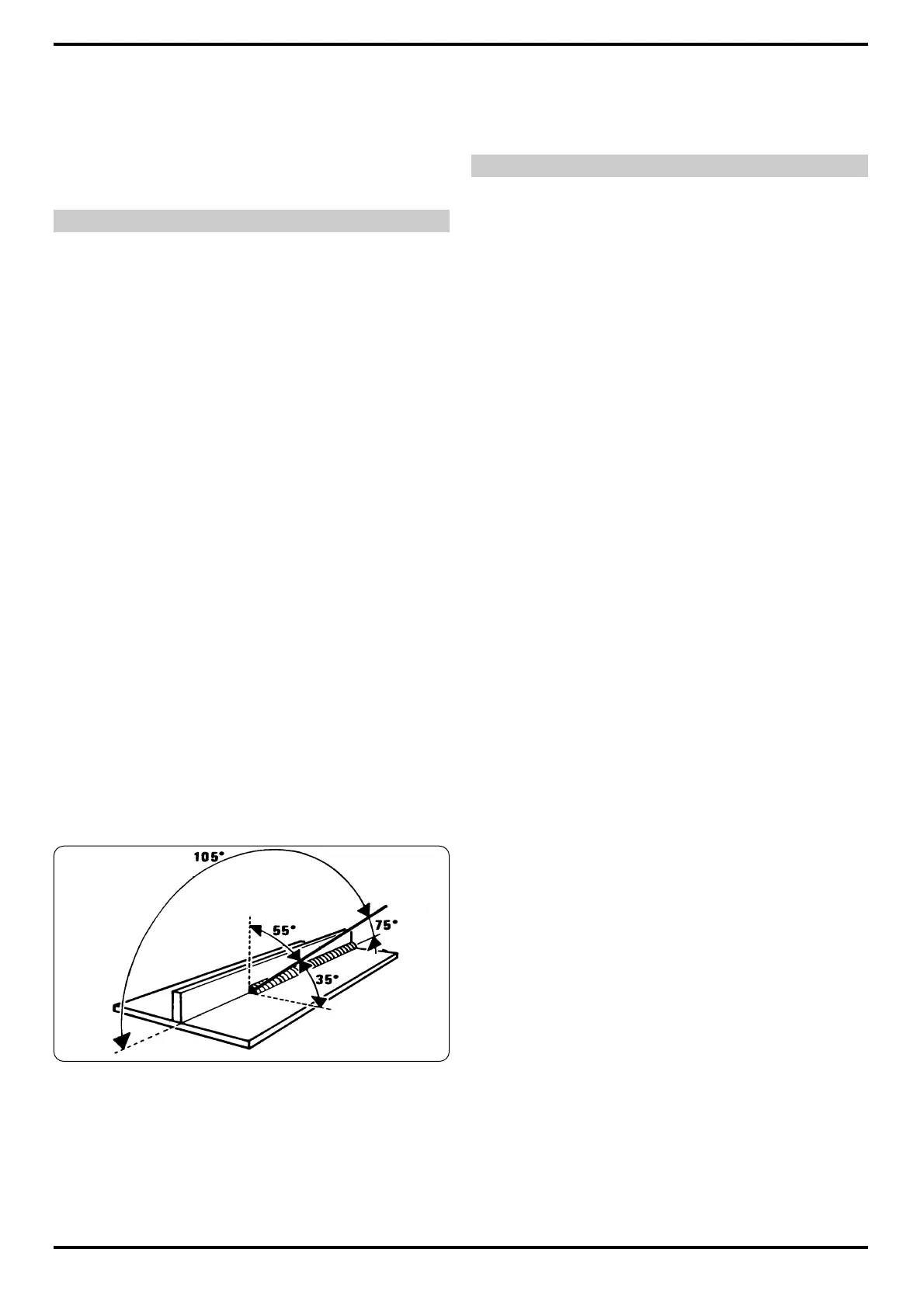

For the correct welding angle see figure.

5.2 WELDING ALUMINIUM

The welding machine must be prepared as for welding

mild steel with gas protection, but with the following diffe-

rences:

l 100% ARGON as the protection gas for welding.

l A wire having a composition suited to the base material

to be welded.

For welding ALLUMAN: 3÷5% silicon wire

l For welding ANTICORODAL: 3÷5% silicon wire

l For welding PERALUMAN: 5% magnesium wire

l For welding ERGAL: 5% magnesium wire

Use abrasive grinders and tool brushes specifically designed

for aluminium. Never use these tools on other materials.

REMEMBER that cleanliness equals quality.

The wire spools must be stored in plastic bags with a

dehumidifier.

See the figure for correct torch inclination.

5.3 WELDING STAINLESS STEEL

The welding machine must be prepared as for welding

mild steel with gas protection, but with the following diffe-

rences:

l Reel of stainless steel wire compatible with the compo-

sition of the material to be welded.

l Cylinder containing 98% ARGON + 2% 02 (recommen-

ded composition)

The recommended torch angle and welding direction are

shown in figure.

6 MAINTENANCE AND CHECKS

6.1 GENERAL NOTES

l Turn off the welding machine and unplug the power cord

from the socket before each checking and maintenance

operation.

l Moving parts can cause serious lesions

l Keep away from moving parts.

l INCANDESCENT SURFACES can cause serious burns.

l Let the unit cool before servicing.

l Periodically remove any dust or foreign matter that may

have deposited on the transformer or diodes; to do so, use

a jet of clean, dry air.

l When replacing the wire roller, make sure the groove is

aligned with the wire and corresponds to the diameter of

the wire used.

l Always keep the interior of the gas nozzle clean to avoid

metal bridges created by welding dross between the gas

nozzle and the contact tip. Make sure the outlet hole of the

contact tip has not expanded excessively; if so, replace.

l Strictly avoid striking the torch or allowing it to suffer vio-

lent impact.

6.2 REPAIRING THE WELDING MACHINE

Experience has shown that many accidents are caused by

repairs performed incorrectly. That is why it is just as

important to check a repaired welding machine carefully

and completely as it is for a new welding machine.

In addition, this protects the manufacturer from being held

liable for defects when the true fault lies elsewhere.

6.2.1 Instructions for performing repairs

l After rewinding the transformer or inductance, the wel-

ding machine must pass the applied voltage tests as indi-

cated in table 2 of paragraph 6.1.3 of the standard EN

60974.1 (CEI 26.13). Compliance must be verified as spe-

cified in 6.1.3.

l If no rewinding has been done, a welding machine that

has been cleaned and/or revised must pass an applied

voltage test with test voltage values equal to 50% of the

values given in table 2 of paragraph 6.1.3. Compliance

must be verified as specified in 6.1.3.

l After rewinding and/or replacing parts, the no-load vol-

tage must not exceed the values given in paragraph 10.1

of EN 60974.1.

l If the repairs have not been performed by the manufac-

turer, repaired welding machines in which some compo-

nents have been replaced or altered must be marked in

such a way that the person who performed the repairs is

clearly identifiable.

l After making repairs, take care to re-order the wiring so

that there is certain insulation between the primary side

and the secondary side of the machine. Prevent the wires

from coming into contact with moving parts or parts that

heat up during operation. Replace all clamps as on the ori-

ginal machine to prevent a connection from occurring

between the primary and secondary side if a conductor

accidentally breaks or disconnects.

Loading...

Loading...