The proper installation and maintenance of packing to seal a pump

shaft is not difficult but must be properly done to provide good pack-

ing and pump shaft sleeve life. All packing must be allowed to leak.

This leakage is the only lubrication for the packing and additionally

provides cooling to remove part of the frictional heat built up

between the shaft sleeve and the packing. Failure to allow sufficient

leakage will result in short packing and shaft sleeve life and

increased power consumption of the pumping unit. It is entirely possi-

ble to stall a centrifugal pump by clamping the packing gland down.

Dean pumps are shipped from the factory without packing in the

seal chamber. A complete set of die molded packing specified for

the service is shipped with the pump in a separately labeled carton.

The pump seal chamber must be properly packed before the pump

is put into service.

The seal chamber may be packed either with or without a lantern

ring (also known as a seal cage or lantern gland) as the service of

the pump dictates. When the pump section pressure is above 100

psig a lantern ring is not recommended. When the pump is a self-

priming type, the lantern gland should be used to provide a means

to seal against air leakage into the pump during the priming cycle.

PURPOSE OF LANTERN RING

Lantern rings are made of Teflon or suitable metal as the service

demands. They are of split construction and may be easily installed

or removed without disassembling the pump. A lantern ring is used

in the seal chamber with packing for these reasons:

1) To permit the introduction of a sealing liquid into the seal chamber

to prevent leakage of air into the pump through the packing when

the pump suction pressure is less than atmospheric pressure. The

sealing liquid may be from an internal seal connection or from an

external source. This is required on self-priming pumps.

2) To permit introduction of grease, oil or other suitable lubricant to

the packing to provide lubrication or cooling.

INTERNAL SEAL CONNECTION TO THE LANTERN RING

An internal seal connection is used to inject pumpage from the pump

casing into the lantern ring through the lantern ring connection of the

seal chamber to seal the pump against air leakage as noted above.

It can be used only when the pumped liquid is clean and non-abra-

sive.

The pumped liquid introduced through the internal seal connection to

the lantern ring will not seal the pump against air leakage through

the packing when the pump is idle or on stand-by service.

EXTERNAL SEAL CONNECTION TO THE LANTERN RING

The sealing liquid introduced to the lantern ring may be from a

source external to the pump. It must be introduced at a pressure

above seal chamber pressure and must be non-corrosive, non-abra-

sive and 150°F or less in temperature. The connection is made to the

lantern ring connections on the pump seal chamber.

The lantern ring connection on the pump seal chamber is also used

to introduce grease, oil, or other suitable lubricants to the lantern

ring.

LANTERN RING NOT USED

When the pump suction pressure is above atmospheric pressure or

the seal chamber is pressure sealed (no impeller balance holes) and

neither internal nor external liquid or lubricant is required to the

packing, the lantern ring is not used and the seal chamber is packed

full with rings of packing.

PACKING INSTALLATION

These instructions apply to the conventional woven, braided, folded,

and wrapped packings. Packings of multifilament Teflon, braided

carbon filament, compressed carbon sheet, and other special types

or materials may require special installation techniques.

The way in which the packing is installed in the seal chamber is

important to the good service life of the packing and the shaft

sleeve. Incorrect installation will lead to excessive leakage and may

cause higher power requirements.

The use of a packing tamper (split bushing) is recommended to

properly seat the packing rings. Such a tool is easily made from

wood or metal in the form of a hollow cylinder. The inside diameter

must be slightly larger than the shaft sleeve and the outside slightly

smaller than the seal chamber bore. Split the piece lengthwise to

allow insertion in the seal chamber. More than one length of pack-

ing tamper may be necessary. Suit the lengths to the particular

pump.

All packing rings furnished by Dean Pump are die-molded to fit the

seal chamber. To place a ring on the shaft sleeve, open the ring at

the split at the right angle to the plane of the ring. This will best

retain the molded form and avoid distortion. Successive rings should

be installed with the joints at 90° intervals.

Foil wrapped packing must be installed with the foil laps running in

the direction of shaft sleeve rotation on the inside of the ring.

Metallic packing should be lubricated, on the wearing face only,

with a dry graphite lubricant before insertion.

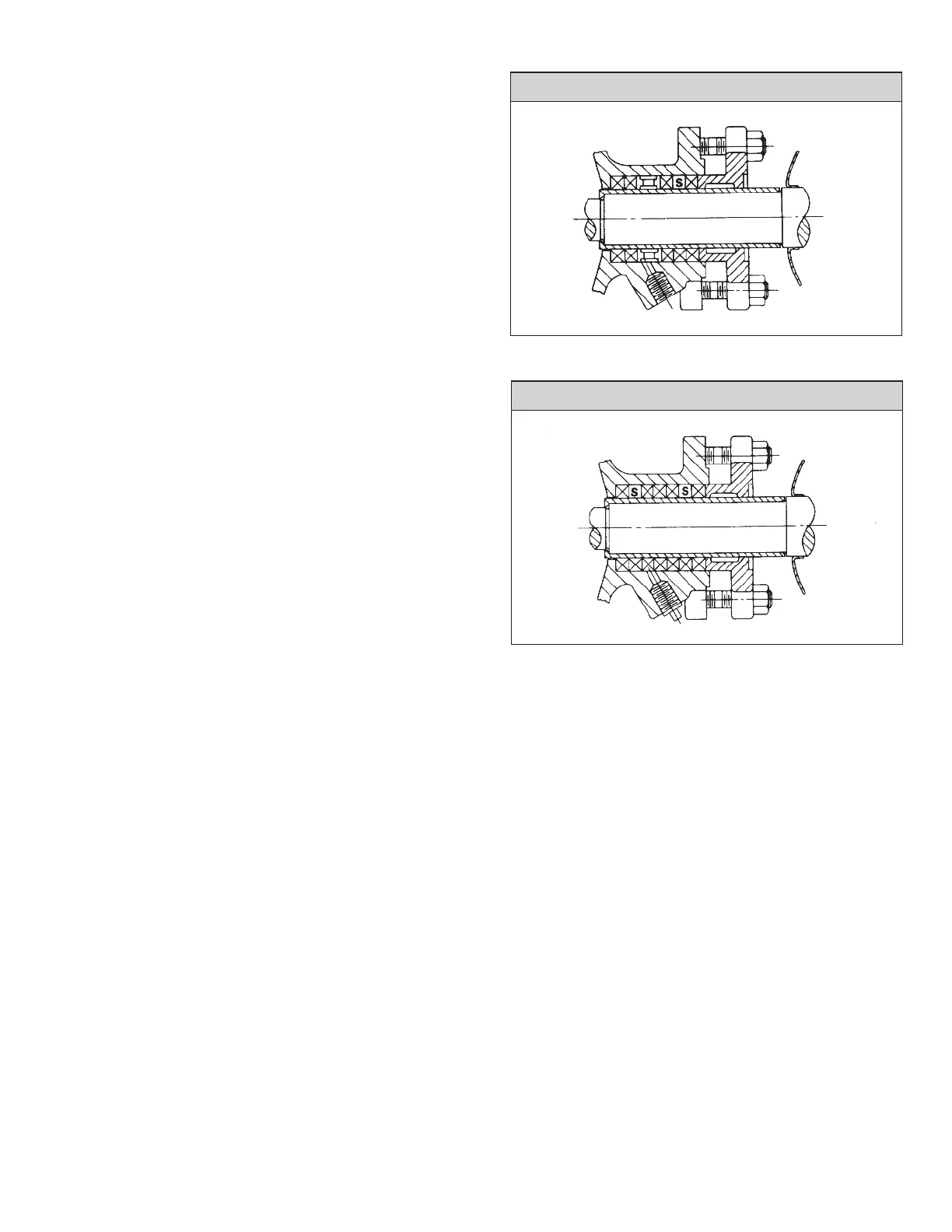

PACKED SEAL CHAMBER WITH LANTERN RING

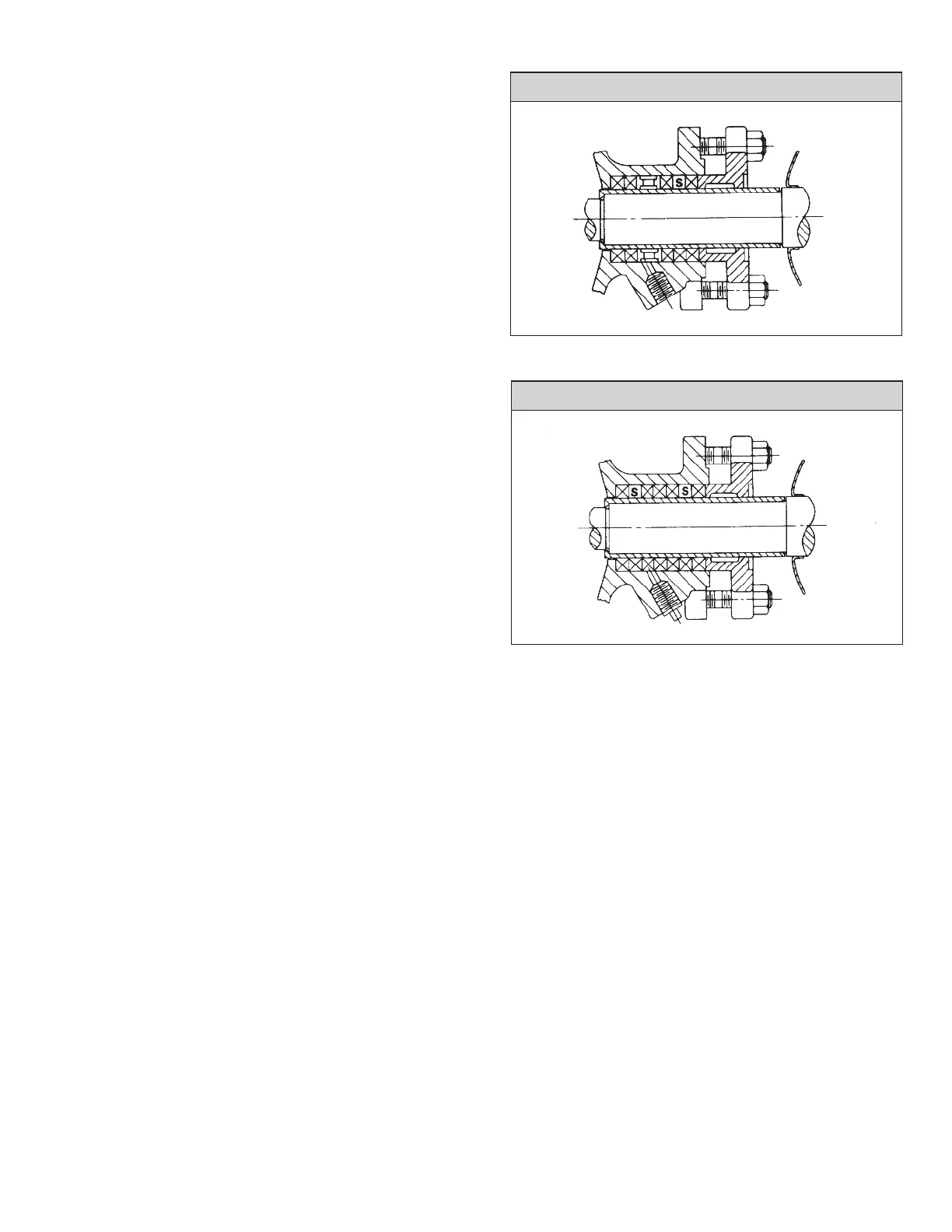

PACKED SEAL CHAMBER WITHOUT LANTERN RING

S = When soft packing rings are furnished in a set with metallic rings, install the soft

rings in the locations marked “S”.

23

INSTALLATION AND MAINTENANCE OF SEAL CHAMBER PACKING

Loading...

Loading...