5

piping to remove the distorting load, and realign the pump

and driver.

9) The pump and driver alignment must again be checked at the

operating temperature and alignment corrected under the hot

condition.

10) After about two weeks of normal pump operation the pump

and driver alignment should again be checked under the hot

condition. If alignment is still correct, the driver feet may be

doweled to the baseplate. If the alignment has changed,

realign the unit and recheck after two weeks. NOTE: Refer to

MC 1.2.34 FBP when Dean FRP baseplates are used.

SUCTION AND DISCHARGE PIPING

Suction and discharge nozzle sizes of Dean pumps are selected

for proper performance of the pumping unit and are not intended

to determine the suction and discharge pipe sizes. Pipe sizes must

be determined by the user based on the system requirements.

Suction piping should have a minimum friction loss and thus

should be as short and straight as possible with a pipe diameter

as large as economically feasible for the flow rate handled.

Suction piping should never be smaller in diameter than the suc-

tion nozzle size. When the suction piping is larger than the suction

nozzle size an eccentric reducer is required at the suction flange

and must be installed with the taper located on the underside to

eliminate air or vapor pockets. The section of piping attached to

the suction flange of the pump should be straight for a length of

eight pipe diameters or more.

Discharge piping may be the same size as, larger, or smaller than

the discharge nozzle as the system flow may demand.

In new installations or rebuilt systems, dirt, pipe scale, welding

slag, and general construction debris may get into the piping. It is

important to prevent this material from entering the pump and

damaging pump parts, mechanical seal faces, or seal chamber

packing. Mechanical seal parts are especially subject to damage

even by very small particles. To prevent damage, a strainer or fil-

ter installed in the suction line is recommended. Commercially

able to the pump and should be considered at the time the system

is designed.

NOTE: See page 26 for Installation of pHP self-priming pumps.

PUMP AND DRIVER ALIGNMENT

Proper running life of a pump and driver unit depends on the accu-

racy with which the axis of the driver shaft coincides with the axis

of the pump shaft when the unit is running. Although pumps and

drivers are check aligned at the factory, this is only to confirm that

the unit can be aligned in the field and handling during shipment

and installation will cause the alignment to change.The pump and

driver alignment must always be checked and corrected before the

baseplate is grouted to the foundation and again before the pump

is first started. If the baseplate mounting instructions have been

carefully fol lowed, no difficulties in making the alignment should

be experi enced. Failure to properly align the unit will result in

vibra tion, short bearing life, and reduced mechanical seal or shaft

packing life.

Pumps are not constructed to be used as pipe anchors. Both suc-

tion and discharge piping must be supported independently of the

pumping unit and thermal expansion joints provided to guard

against expansion loads on the pump. Pipes should be anchored

between the expansion joint and the pump and as closely to the

pump as possible. Failure to provide proper piping support and

expansion joints may impose strains on the pump ing unit which

will result in serious misalignment. Any and all loads upon the

pump must be with-in the maximum allowable values given in the

section titled “Allowable Nozzle Loads” on page 6.

No allowance for thermal expansion is made for motor driven

units in mounting the driver. Allowance for turbine mounting

should be in accordance with the turbine manufacturer’s recom-

mendations. Final alignment must always be checked and correct-

ed at the operating temperatures of the pump and driver.

Misalignment of the two shafts is of two kinds. The first of these is

angular misalignment where the axis of one shaft is at an angle

from the other. The other is offset alignment where the center of

one shaft is offset from the center of the other shaft. These effects

usually occur together so that both angular and offset misalignment

are present.

Coincident alignment of the driver and pump shaft is measured at

the faces of the coupling hubs. Because of the variety of coupling

types furnished at customer’s request, the procedure here given is

general in nature but may be applied by simple adaption to most

coupling types.

The first step is to remove the spacer from the coupling. To one of

the remaining coupling hubs, firmly seated on the shaft, attach a

dial indicator. Let the indicator button ride on the face of the other

coupling hub and near the outside diameter. Rotate the shaft on

which the dial indicator is mounted, allowing the indicator button

to move on the stationary coupling hub. The indicator dial move-

ment will show the difference in distance between the two hubs.

This indicates the amount of angular misalignment between the

hubs and therefore the shaft axes. Good practice suggests align-

ment to within 0.002" T.l.R.

available strainers or filters as recommended by their manufactur-

ers can do an excellent job. In addition, special filtering and

mechanical seal flushing may be required. Consult your Dean rep-

resentative. Suction line screens or strainers may usually be

removed when, after several days of use, no dirt has been collect-

ed and the system is clean.

Remember that screens and filters in the suction line are restrictive

devices which reduce the net positive suction head (NPSH) avail-

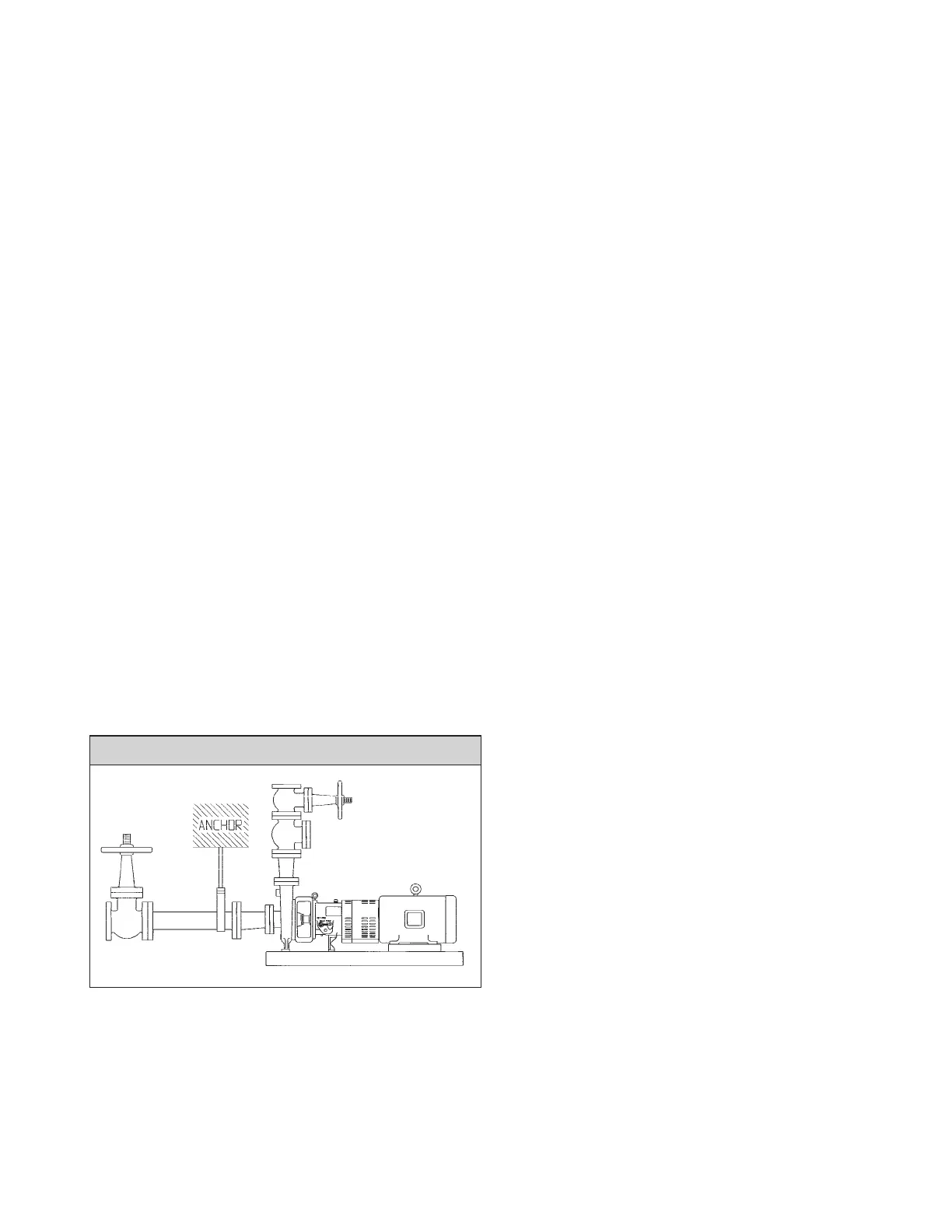

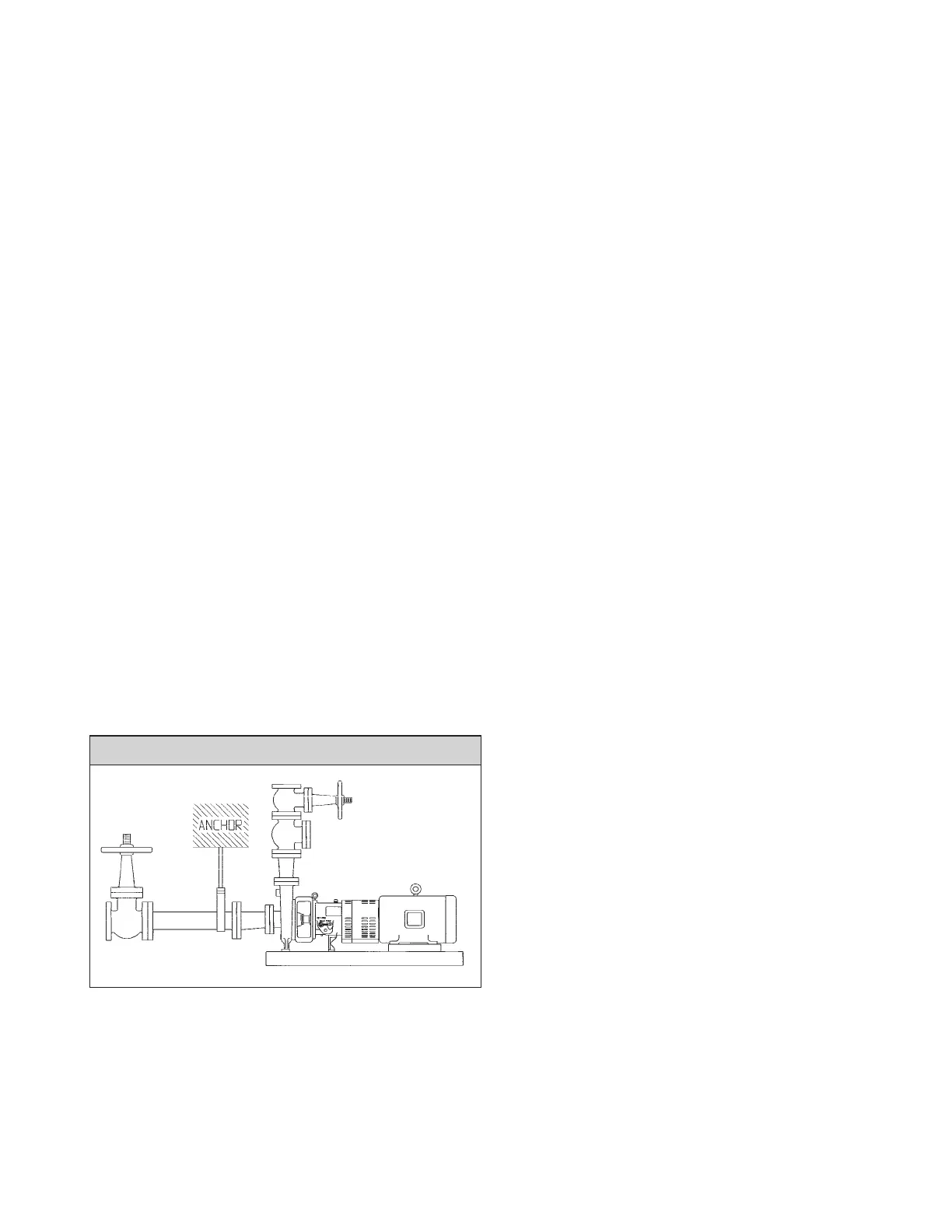

TYPICAL PUMP PIPING

Loading...

Loading...