11. TROUBLESHOOTING

Many pr

oblems that appear to be MFC-related may actually be caused by another part of the

system. Go through the step-by-step Troubleshooting Guide (Appendice 16.3) before removing the

MFC from service.

Environmental factors may affect MFC performance (see Table 1) but these are easily resolved

using a simple troubleshooting checklist (see Table 2).

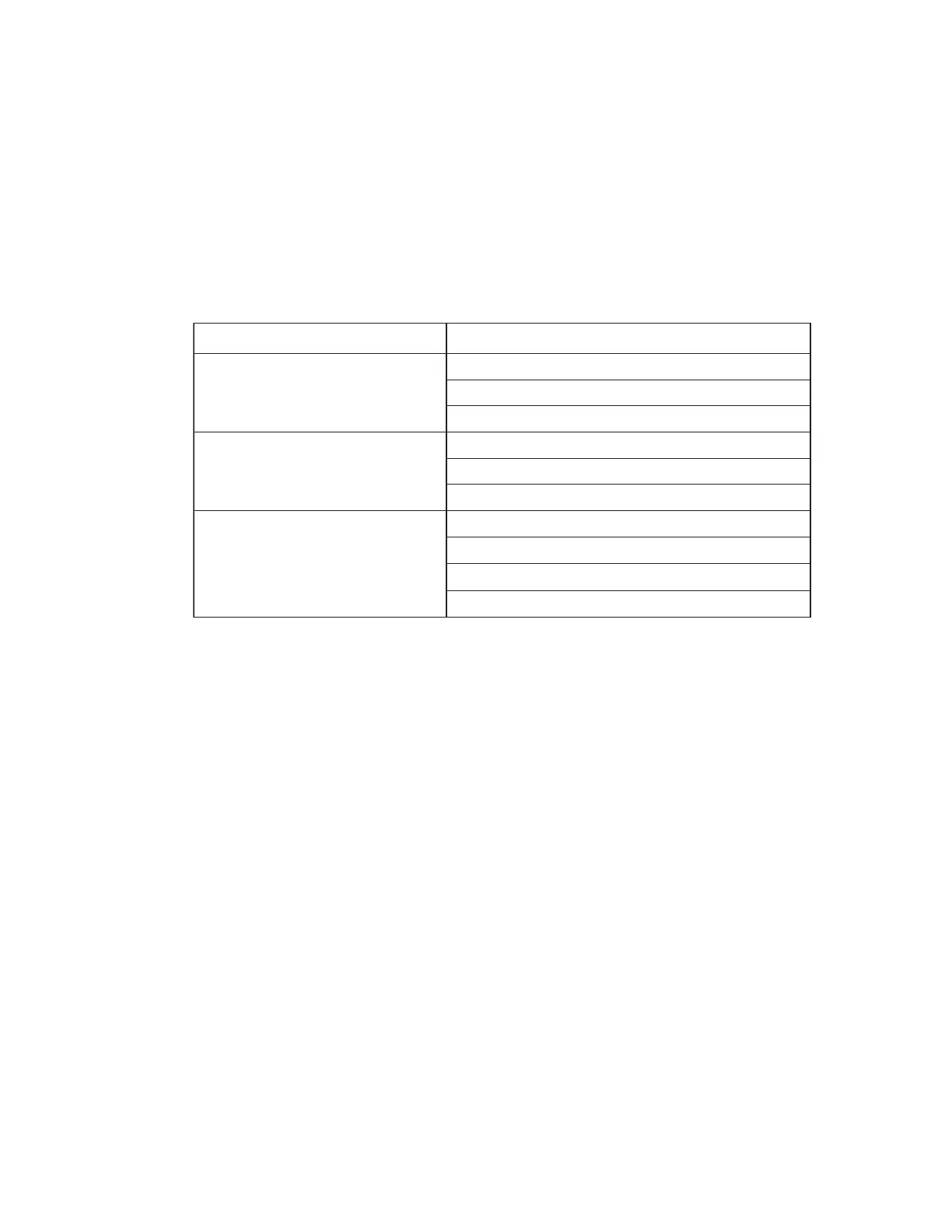

11.1 Environmental Factors

Table 1. Environmental factors

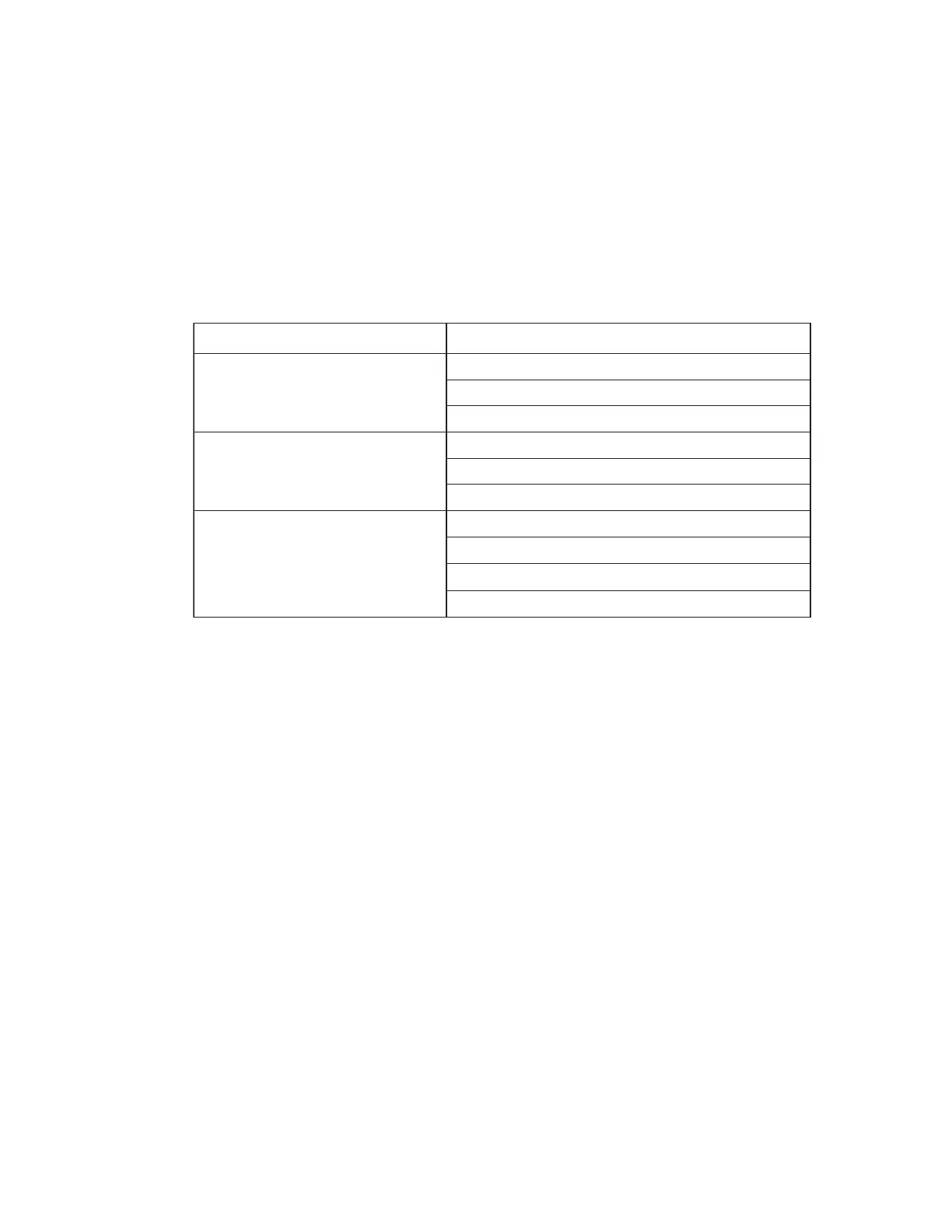

11.2 MFC Troubleshooting Checklist

Check For These Factors:

- Verify that the supply voltage is correct.

- Verify that the grounding is consistent.

- Verify that the setpoint signal at the MFC connector is the same as the setpoint signal

coming from the tool.

- V

erify that the Output (Indicated Flow) of the fl

ow controller is the same at the input of the

tool.

- Verify the valve voltage response.

- Move the setpoint upward and downward, looking for the valve voltage to change

accordingly.

- Compare recent valve voltage to past valve voltage. If it has changed and the other

parameters have not then a failur

e is likely

.

11

SYMPTOMS CAUSES

Inaccurate flow (span shifts)

•

Temperature (steady state and transient)

•

Inlet pressure (steady state and transient)

•

Power supply problems, electrical interference

Control problems

•

Differential pressure not within operating range

(cannot reach setpoint, oscillation)

•

Inlet pressure not stable

•

Cable losses (too much ground current

Zero problems

•

Temperature (steady state and transient)

(indicated zero not stable)

•

Inlet pressure (steady state and transient)

•

Power supply problems, electrical interference

•

Attitude sensitivity

©2005 Celerity

, Inc.

#199-001-0006 REV

.F 4/05

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...