For technical questions, please call 1-800-444-3353;

Troubleshooting section at end of manual.

SKU 93305 Page 7

IMPORTANT: Before using for the rst time, the spray gun must be cleaned

using a solvent based thinner. If not removed, the red oil used by the

manufacturer for testing and corrosion protection may contaminate paint.

IMPORTANT: The Spray Gun must be cleaned immediately after use.

Improper cleaning is a common reason for the Spray Gun not to work.

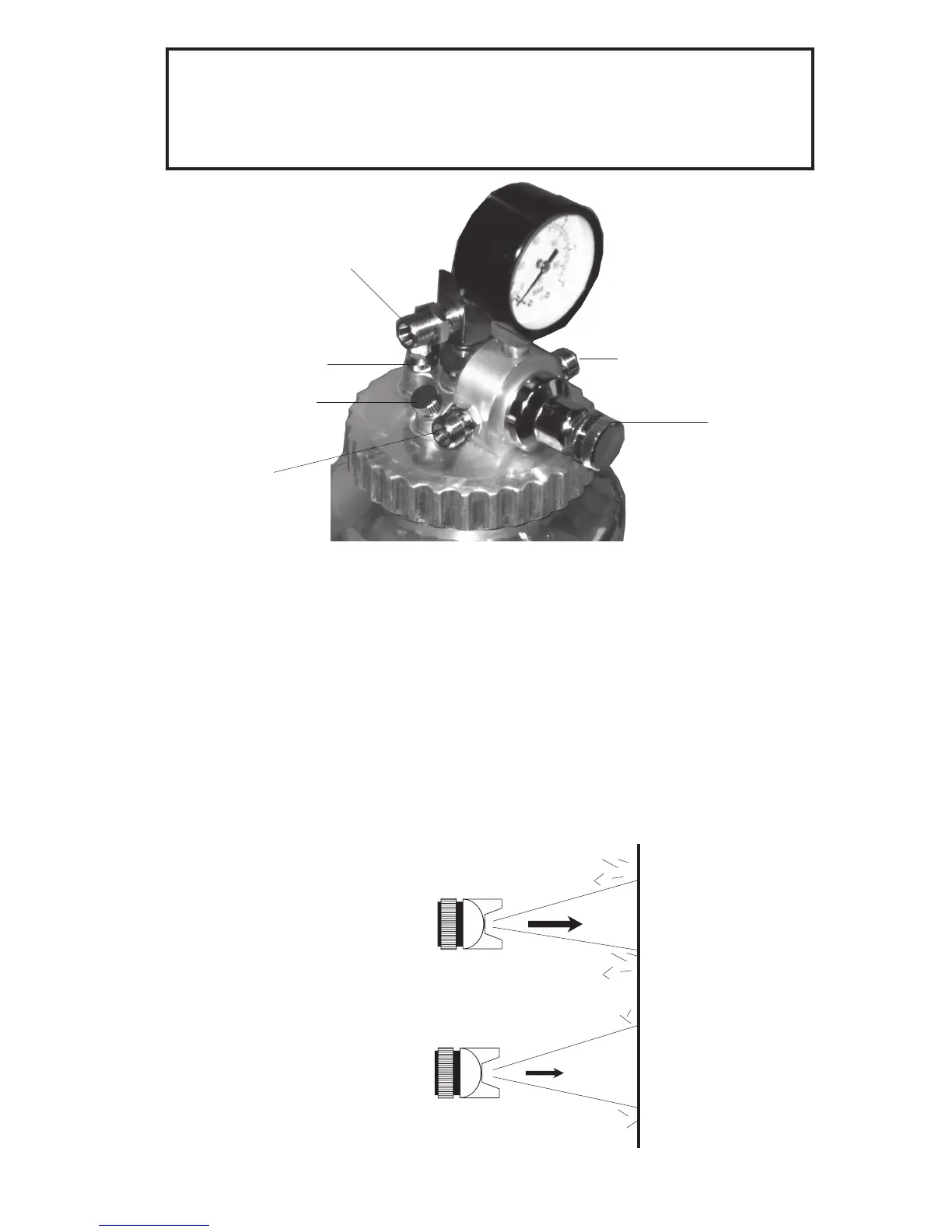

FIGURE 2

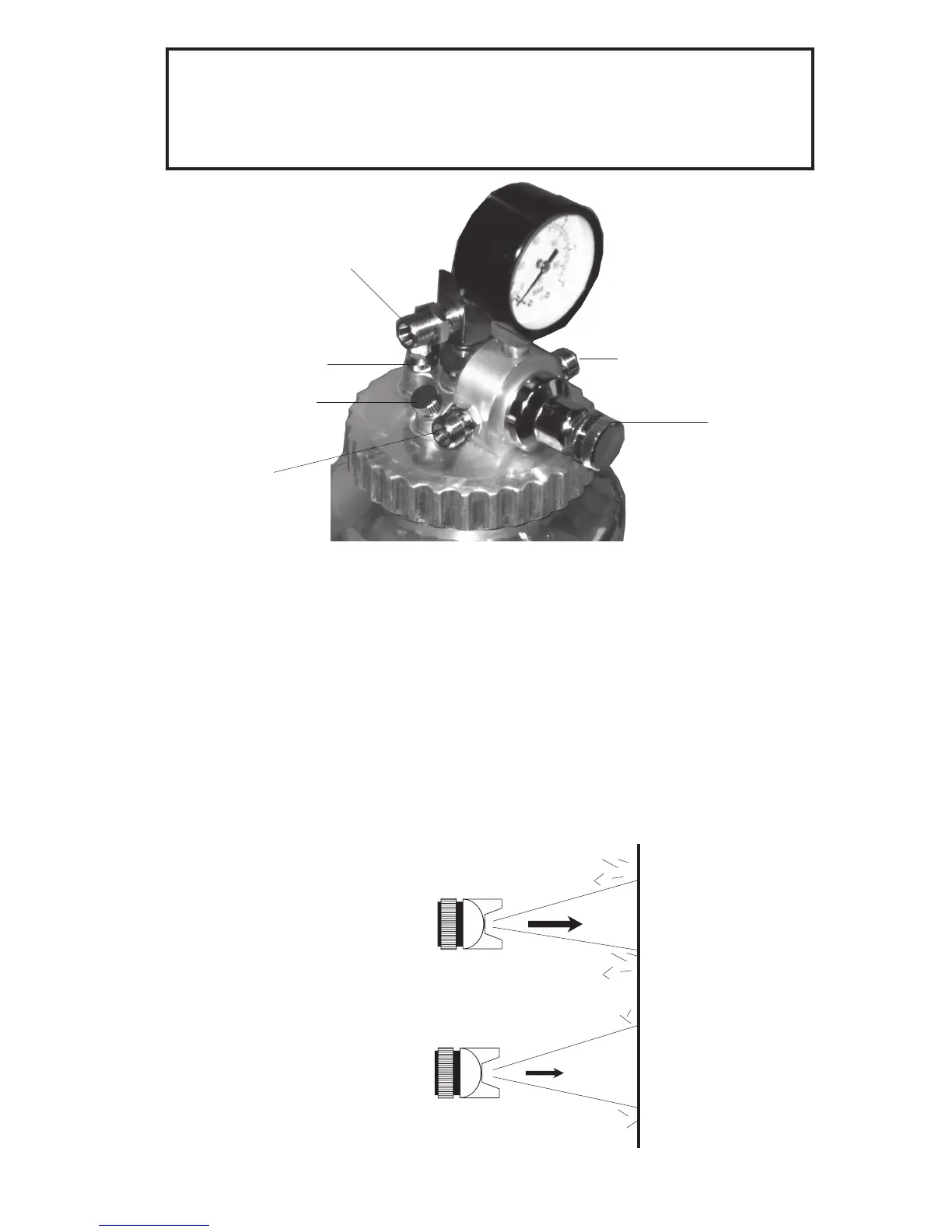

A Comparison: Conventional versus HVLP Spray Guns

Because conventional spray guns require a much higher air cap pressure to atomize

the paint than HVLP Spray Guns, conventional guns have lower transfer efciencies

and more overspray.

This translates to a signicant paint/material savings for HVLP guns, in addition to

making them more environmentally friendly.

To qualify as HVLP, the dynamic air pressure going in the Air Cap must be a maximum

of 10 PSI. The lower the air pressure, the less bounce back and overspray.

Note: Due to the viscosity of latex and other water-based paints, they are not

recommended for use with this or other HVLP (High Volume Low Pressure) spray-

ers.

See FIGURE 3 below.

Conventional

HVLP

FIGURE 3

Air Outlet Connector (36)

Safety Valve (2)

Fluid Flow Knob (11)

Fluid Outlet (39)

Air Inlet Connector (36)

Air Regulator (24)

Loading...

Loading...