79032966 A Rev. 01-53

General Information

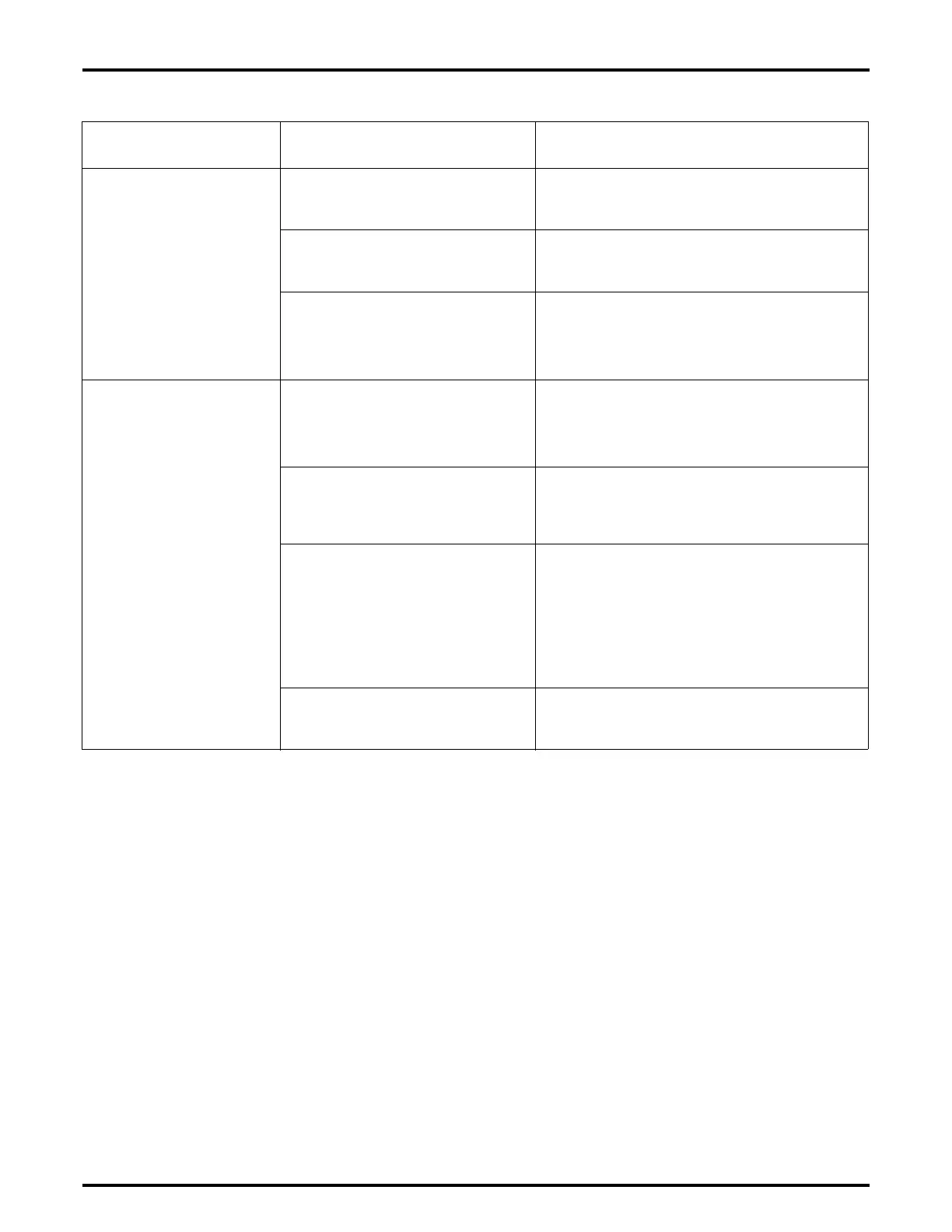

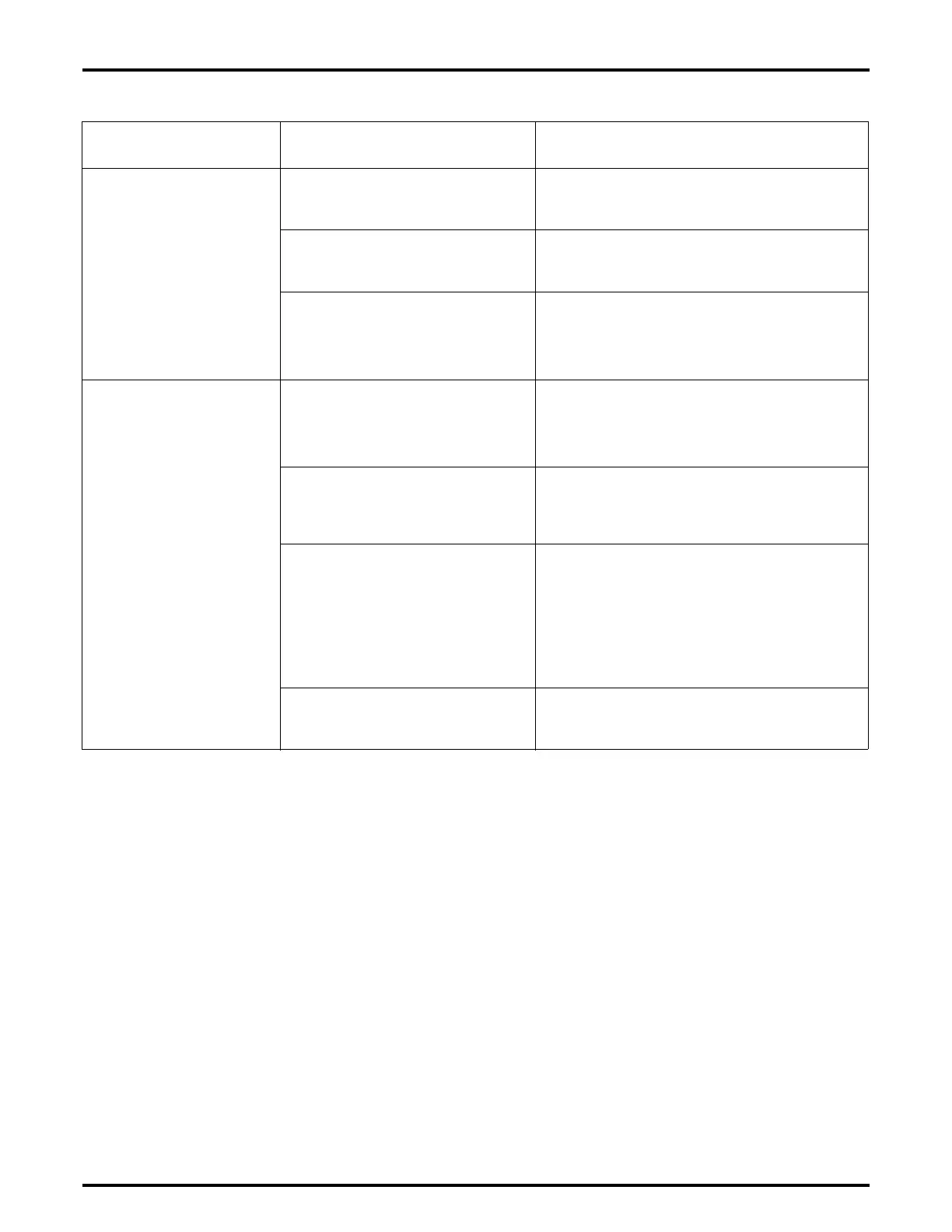

TABLE 2 Belt Extended Beyond Idler or Sheave Take Up

Symptom / Observation Possible Causes Corrections / Remedy

Idler spring can not be

adjusted to properly

tension drive belt.

Belt extended and worn. Properly install a new original equipment belt

and adjust belt tension and idler spring.

Belt tensile member broken. Properly install a new original equipment belt

and adjust belt tension and idler spring.

Belt over loaded. Reduce load on belt.

Properly install a new original equipment belt

and adjust belt tension and idler spring.

Belt strands not equal. Sheaves not aligned (not equal

work done by each belt strand).

Align the sheaves.

Properly install a new original equipment belt

and adjust the belt tension and idler spring.

Belt tensile members broken or

damaged from not correct

installation.

Properly install a new original equipment belt

and adjust the belt tension and idler spring.

Trash or debris fell into the sheave

grooves.

Clean trash or debris from the sheave grooves.

Correct the cause of trash or debris entering

the sheave grooves and make sure all the

protective shields are installed.

Properly install a new original equipment belt

and adjust the belt tension and idler spring.

Belt strand lengths not matched. Properly install a new original equipment belt

and adjust the belt tension and idler spring.

Loading...

Loading...