General Information

01-52 79032966 A Rev.

Belt Troubleshooting

When troubleshooting a belt drive problem, stand back

and watch the drive while the drive is in operation and

when drive is not. Is there a warm rubber smell? Is the

belt moving around the drive in a normal way? Are there

chirping, squealing, or grinding noises? Is there a deposit

of dust or debris under the drive which will cause

problems with the belts?

When the belt drive makes excessive noise, the belt is

frequently blamed. To find the problem spray the belt with

soapy water while the drive is running. If the noise goes

away, or decreases, the belt is part of the problem. If the

noise is still present, the problem can be caused by other

drive components.

NOTE: Do not use belt conditioner or dressing on the

belts.

Not correctly tightened belt drives can make noise.

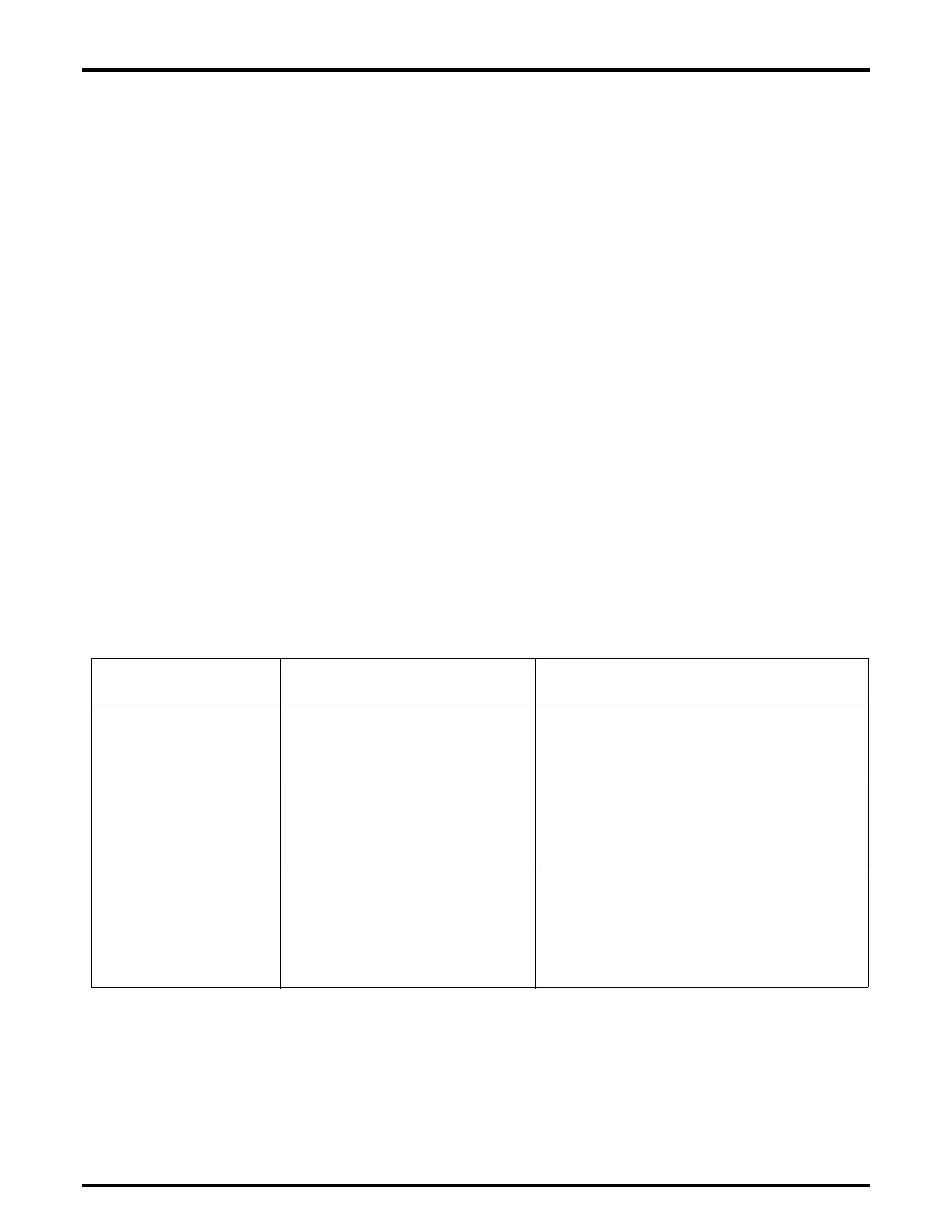

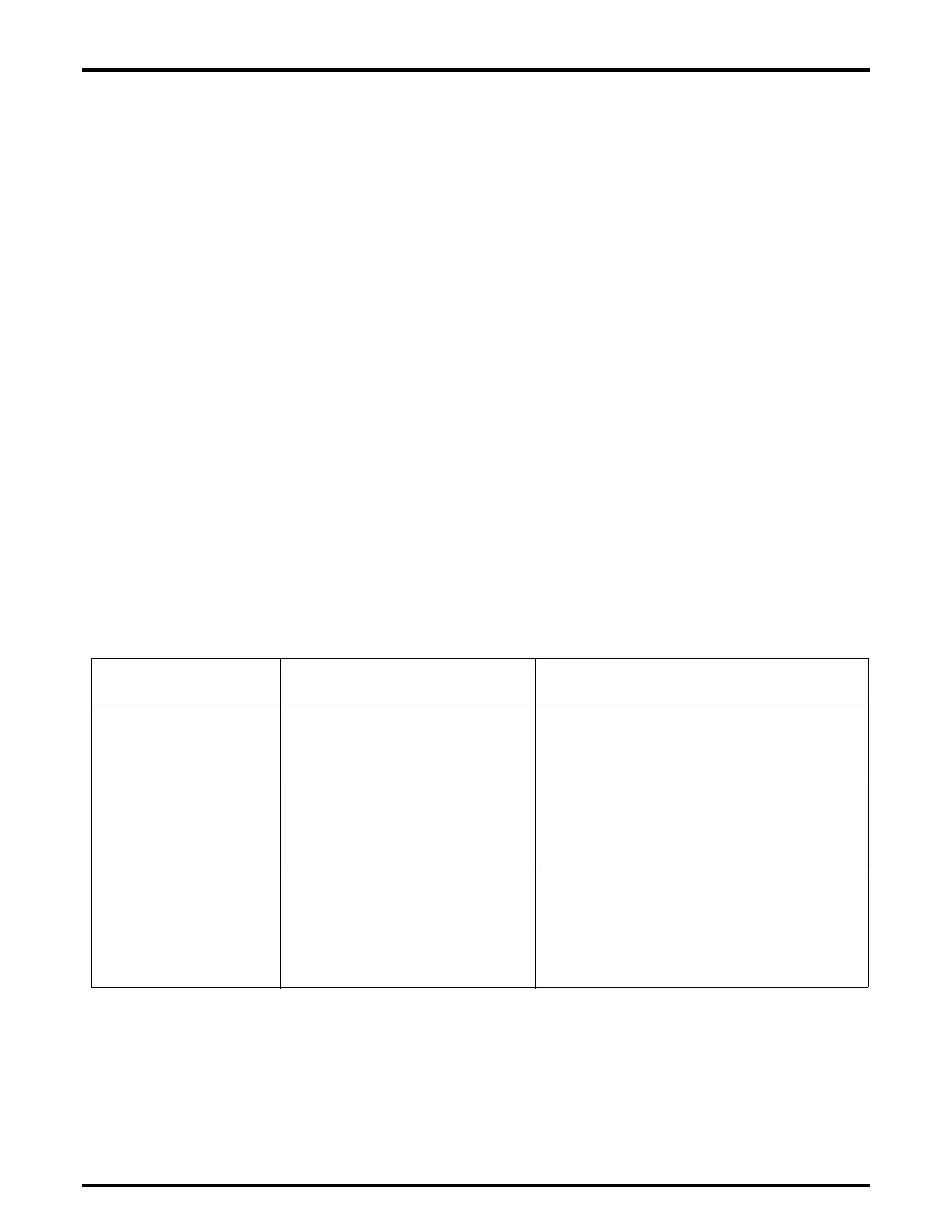

Belt Problem and Wear Guide

The following charts show some of the more common

types of drive belt failures and possible causes for each

failure.

When problem solving a drive belt failure, determine

which problem or SYMPTOM / OBSERVATION shows

the failure that is occurring. Then find the POSSIBLE

CAUSES and take action as shown under the

CORRECTIONS / REMEDY column.

TABLE 1 Short Belt Life and Early Belt Failure

Symptom / Observation Possible Causes Corrections / Remedy

Rapid belt failure, when

no reason can be seen.

Belt tensile member broken or

damaged from not correct

installation.

Properly install a new original equipment belt

and adjust belt tension and idler spring.

Worn driver or driven sheave

grooves (check with groove gauge).

Replace worn sheaves.

Properly install a new original equipment belt

and adjust belt tension and idler spring.

Driver or driven sheave center

distances vary during operation.

Check for failed bearings and loose bearing

housing mounting hardware and repair as

required.

Properly install a new original equipment belt

and adjust belt tension and idler spring.

Loading...

Loading...