10

Introduction/Operation Product Manual - Perma-Cyl

®

w/ FlexFill™ Piping Option

The operator should review the safety precautions found

in the Safety section before conducting a gas or liquid

withdrawal operation. Protective eyeglasses and gloves

should always be worn.

At low ow rates, the Perma-Cyl tank is capable of

delivering warm gas through the line regulator. As the ow

rate increases, the temperature of the gas decreases. If the

cold temperature becomes a problem at a desired ow rate,

an external vaporizer can be added. Attach this vaporizer

directly in series with the gas use connection and place the

line regulator at the exit of the vaporizer.

Safety Circuit

The Perma-Cyl w/ FlexFill Piping Option tanks are equipped

with dual spring operated relief valves (RV-2) and dual burst

discs (BD-1). The dual safety manifold with diverter valve

(V-8) is standard on these vessels. This allows for change

out of safety relief devices without the need to empty the

tank. These devices are used to automatically relieve excess

pressure in the vessel and cannot be isolated by use of a

valve. Replacement of these relief devices should only be on

a "like for like" basis. Substitutes should be avoided unless

approved by the manufacturer. Purge valves (V-7) can be

used to relieve pressure before removing safety devices.

Vent/Full Trycock

The vent valve (V-9) is used to relieve excess pressure in

the cylinder. On Perma-Cyl systems the vent valve is a gray

handled globe valve. When installed indoors, the vent line

should be piped outdoors using 1/2" nominal copper or the

equivalent stainless steel hose. The vent valve also serves as

the full trycock during lling operations. When the Perma-

Cyl tank is lled by trucks other than Orca

™

MicroBulk

Delivery System trucks, the full trycock must be used to ll

the vessel. When liquid starts to spit out of this valve while

being lled, the lling process should be terminated.

Other Piping Circuits and

Components

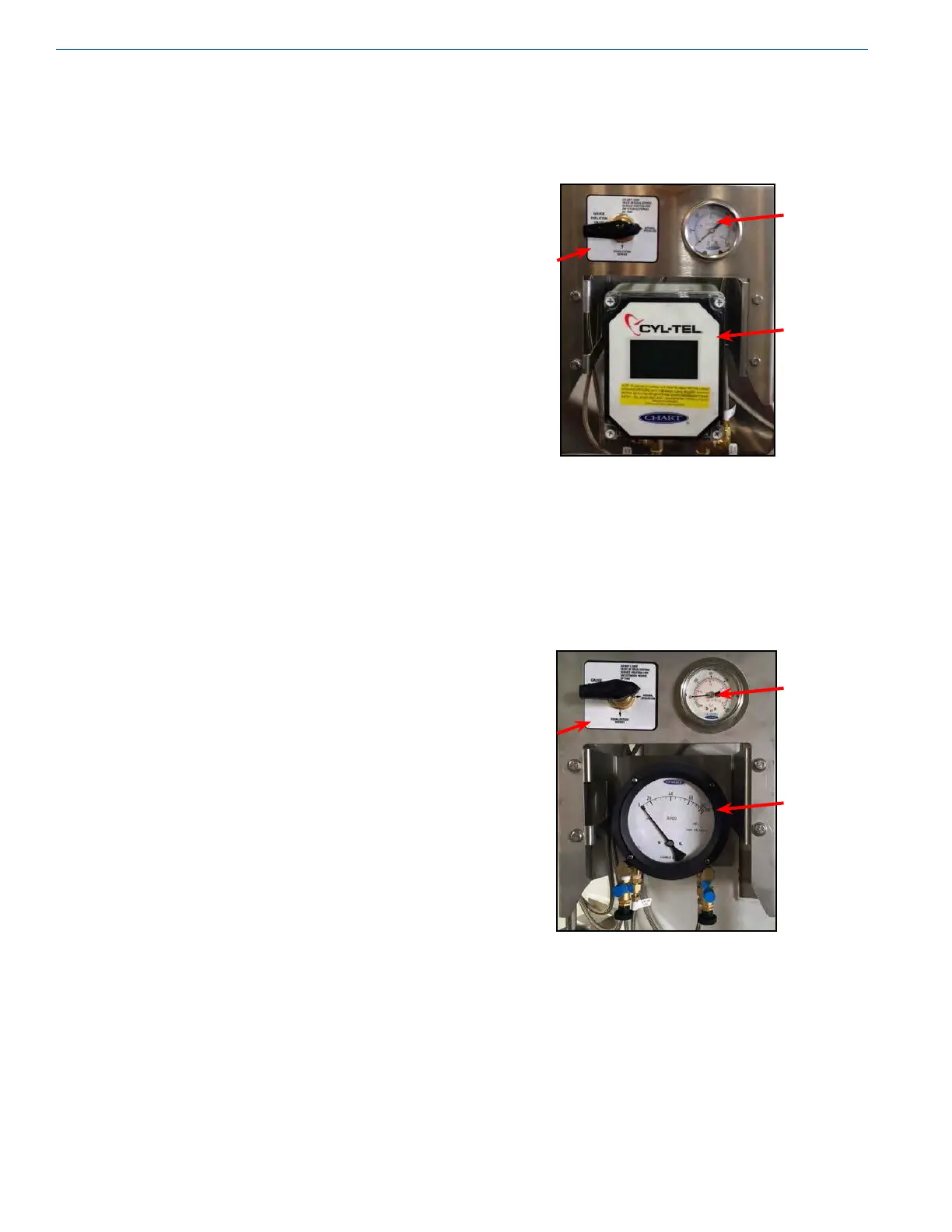

Phase Lines and Liquid Level Gauges

The Perma-Cyl tank is equipped with both a low pressure

phase line (F) located on the top of the vessel and a high

pressure liquid phase line (E) located on the bottom of the

vessel. These lines are connected to a differential pressure

gauge (Ll-1) which is used to indicate the amount of product

in the vessel. The standard DP gauge used by Chart is the

Cyl-Tel

®

Liquid Level Gauge. Customers can specify other

models as options such as the WIKA Analog DP Gauge (see

photos 1 & 2 on next page).

Photo 1

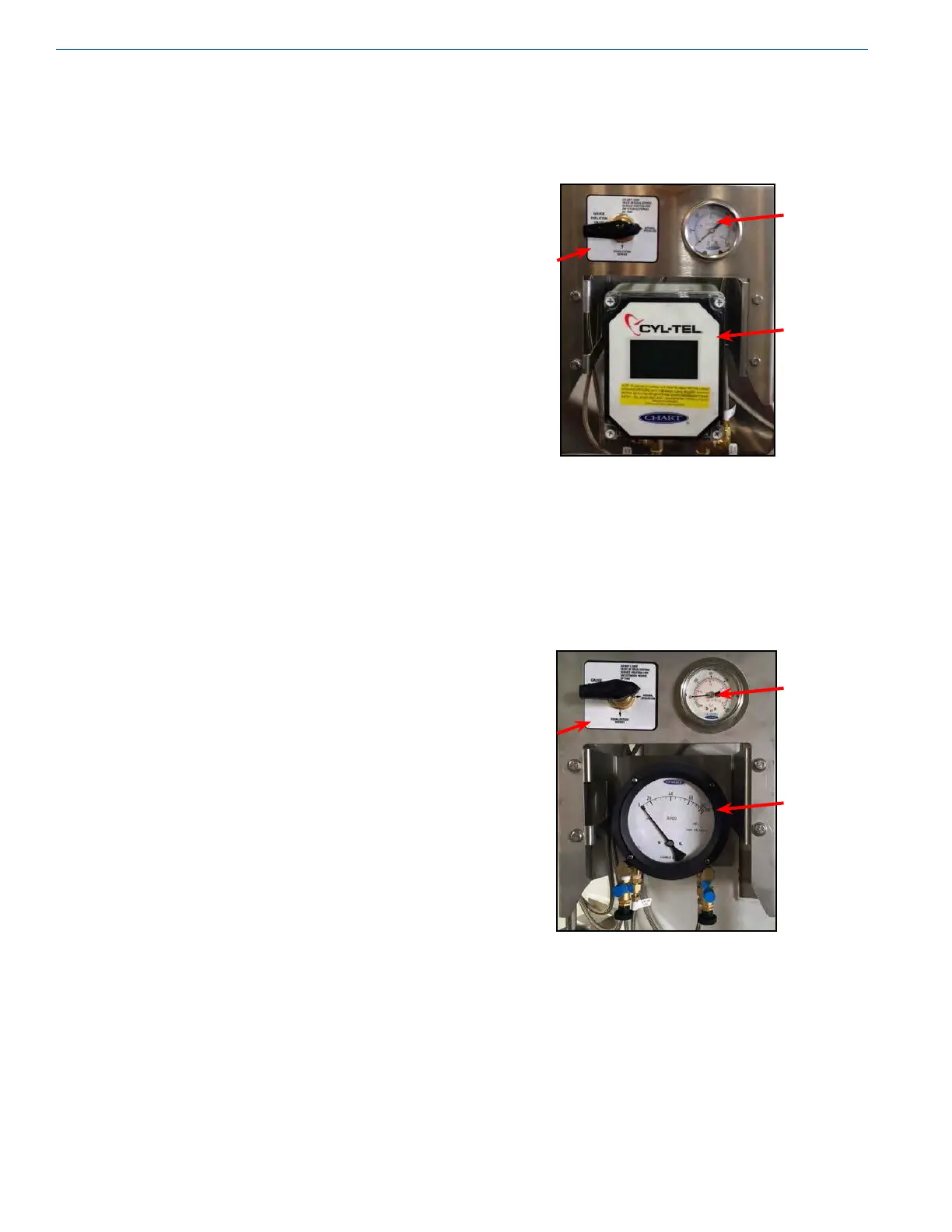

Four-Way Valve (see photos 1 & 2)

The four-way valve (V-11) is used as the primary isolation

valve between the DP gauge and the phase lines from the

tank. This four-way valve also provides an easy method to

check the zero on the DP gauge. By turning the valve into

the equalization position, the DP gauge can be zeroed and

isolated from the tank pressure for removal or replacement.

Photo 2

Pressure Gauge (see photos 1 & 2)

A single pressure gauge (R-1) on the Perma-Cyl tank is also

tied into the low phase line and gives the operator a pressure

reading in the gas phase of the vessel. This pressure gauge

can also be isolated with the four-way valve.

Four-Way

Valve

Pressure

Gauge

Cyl-Tel

®

Liquid Level

Gauge

Four-Way

Valve

Pressure

Gauge

WIKA

Analog DP

Gauge

Loading...

Loading...