22

Installation Product Manual - Perma-Cyl

®

w/ FlexFill™ Piping Option

Externally Sited / Gas Use Indoors

Outdoor installations can offer better accessibility for the

Orca

™

Delivery System for lling purposes. Also, lines

do not need to be run except from the tank to the user’s

equipment. Outdoor installations should be made on a

concrete pad. Local soil conditions and seismic codes will

affect the thickness and reinforcement required for the

concrete pad. The Perma-Cyl unit should be bolted to the

concrete pad using appropriate sized anchor bolts. Also in

outdoor installations, a fence can provide added protection

for the Perma-Cyl system and work to eliminate tampering

with any plumbing component.

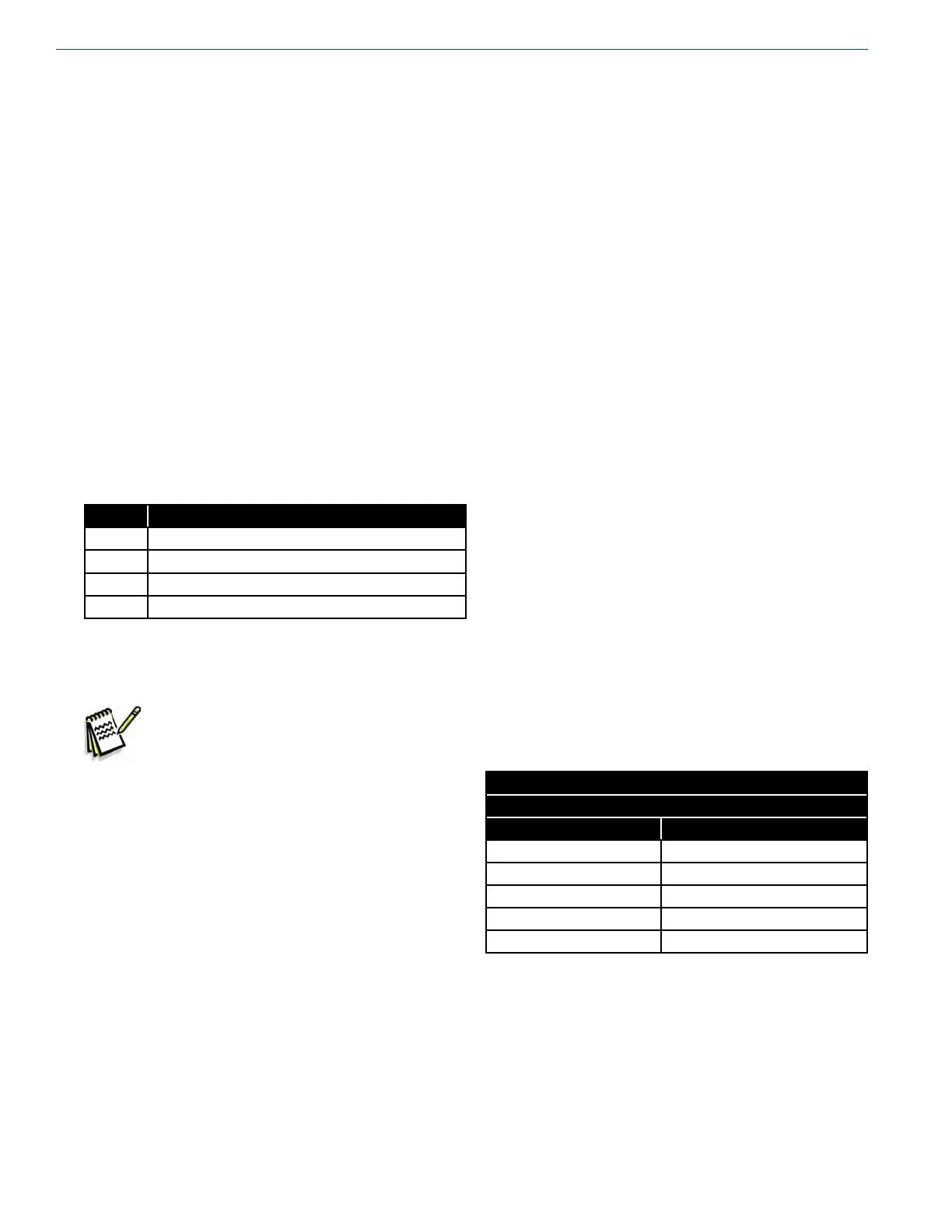

Outdoor Installation Schematic

At a minimum, installation should include a nal line

regulator and a check valve. A typical piping schematic is

depicted in Figure 6.

Item # Description

2 Final Line Regulator

3 Safety Relief Valve

4 Check Valve

5 Coupling Valve for optional back up gas supply

First Fill/Purge Procedure

Note: The Perma-Cyl tank is shipped with low

purity nitrogen gas. Purging is necessary

prior to lling. During rst ll, only ll

the vessel to 75% full to allow for liquid

expansion experienced with a new (warm)

tank. Each ll thereafter can be lled to

100% full. All valves on an empty Perma-

Cyl tank should always be kept closed to

prevent the inner vessel and plumbing from

being contaminated.

Purging and First Fill Procedure

1. Attach the source of liquid purge to the ll connection

of the Perma-Cyl tank.

2. If the ll hose has not been kept under pressure since

the last delivery, it will need to be purged. Purge the

ll hose and connector through the purge valve, if so

equipped, or by loosening the ll connection until vapor

ows from the connection and then retighten. Use the

hose drain on the tank piping if equipped as such.

3. If the Perma-Cyl tank is pressurized, open the vent

valve and blow down to approximately 5 psi. To prevent

drawing atmospheric contaminants back into the tank

during the purging operation, a positive pressure of at

least 5 psig should be maintained in the tank.

4. Partially ll the Perma-Cyl tank with product according

to the table in the next column.

Let liquid build pressure close to safety setting.

Leak check all plumbing circuits while the tank is under

maximum pressure.

While vent gas is still warm and tank is under pressure,

move the four-way valve to the ‘Equalization’ position

and loosen the ttings on either side of the liquid level

gauge to allow the gauge lines to purge with gas. Check

the gas stream coming out of the ttings for evidence of

moisture. Continue to ow the gas until lines have been

purged and there is no visible signs of moisture. Tighten

ttings to stop the ow of gas. Move the four-way valve

to the ‘Normal Operation’ position.

Vent all product out of the liquid valve and close before

pressure drops below 5 psig.

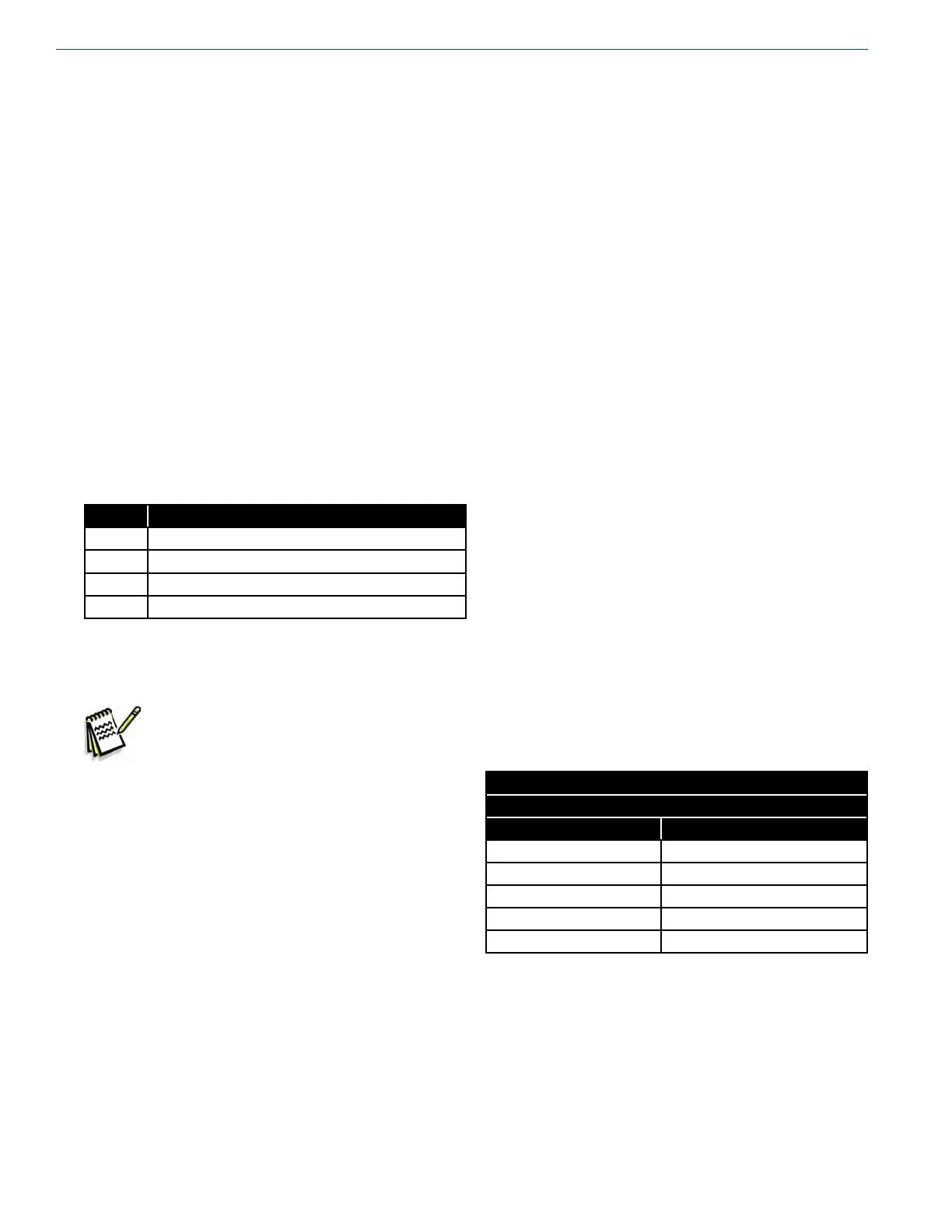

Metered Product per Purge Cycle

Filling Weight Table

Tank Size Product Amount

1000 L Perma-Cyl tank 2000 standard cubic feet

1500 L Perma-Cyl tank 3000 standard cubic feet

2000 L Perma-Cyl tank 4000 standard cubic feet

3000 L Perma-Cyl tank 5000 standard cubic feet

5500 L Perma-Cyl tank 7000 standard cubic feet

5. Fill Perma-Cyl tank with product as indicated in the

table. Primarily use the bottom ll on a FlexFill style

tank. Make sure some product is also routed through

the top ll lines to purge them prior to totally lling the

tank.

Loading...

Loading...