12

Introduction/Operation Product Manual - Perma-Cyl

®

w/ FlexFill™ Piping Option

Pressure Build

The pressure build circuit for the 2000 and 3000 VHP

Perma-Cyl models is used to build pressure back in the

vessel after a delivery or to maintain pressure as liquid is

withdrawn from the vessel. The vessel pressure is set by

adjusting the PB Regulator (R1) shown in Figure 2. Standard

PB set points found in the 09 plumbing option kits are:

MP - 125-09

HP - 300-09

VHP - 450-09

Liquid is drawn off the bottom of the tank, runs through the

PB regulator (R-1), then is vaporized by running through

both the PB vaporizer and the gas use vaporizer. The

vaporized gas then splits and a portion ows through check

valve CV-3 and back to the headspace of the tank. The other

portion goes directly to the customer through the gas use

valve V-1. Liquid serving both the PB and gas use can be

shut off by closing valve V-2.

Note: Closing valve V-1 or V-2 will cut off any

process gas going to the customer through

the gas use valve.

Economizer

The economizer circuit allows for the customer to utilize

the natural heat leak that occurs in every cryogenic storage

vessel. The economizer circuit for the 2000 and 3000 VHP

models is comprised of a check valve (CV-4) which draws

gas directly off the top of the tank and sends it through the

gas use vaporizer in order to warm up the cold vapor prior

to exiting the tank through the gas use valve. Flow through

the 1 psig cracking pressure check valve (CV-4) only

occurs when regulator R-1 closes. Valve V-10 shuts off the

economizer circuit.

Liquid Use

The liquid use circuit for both the 2000 and 3000 VHP

models is similar to the other Perma-Cyl models. This circuit

draws liquid directly up the dip tube and out through the

liquid use valve (V-4). For high ow gas use applications,

the liquid can be piped from the liquid use valve (V-4) to a

stand-alone external vaporizer that is properly sized for the

owrate. In this scenario, the gas use valve on the tank is not

used so the PB and gas use external vaporizers on the tank

become dedicated to pressure building only.

Gas Use

The gas use valve (V-1) on the 2000 and 3000 VHP Perma-

Cyl models is the primary connection point to supply process

gas to the customer. Unlike the other Perma-Cyl models,

the liquid for the process gas comes directly off the bottom

of the tank (C) and travels through the PB regulator (R-1).

The unique design of this model allows for both the PB

vaporizer and the gas use vaporizer to be utilized for process

gas vaporization. After exiting the gas use vaporizer, the gas

splits and supplies both the pressure build and the gas use as

explained in the pressure build explanation for this particular

model of tank.

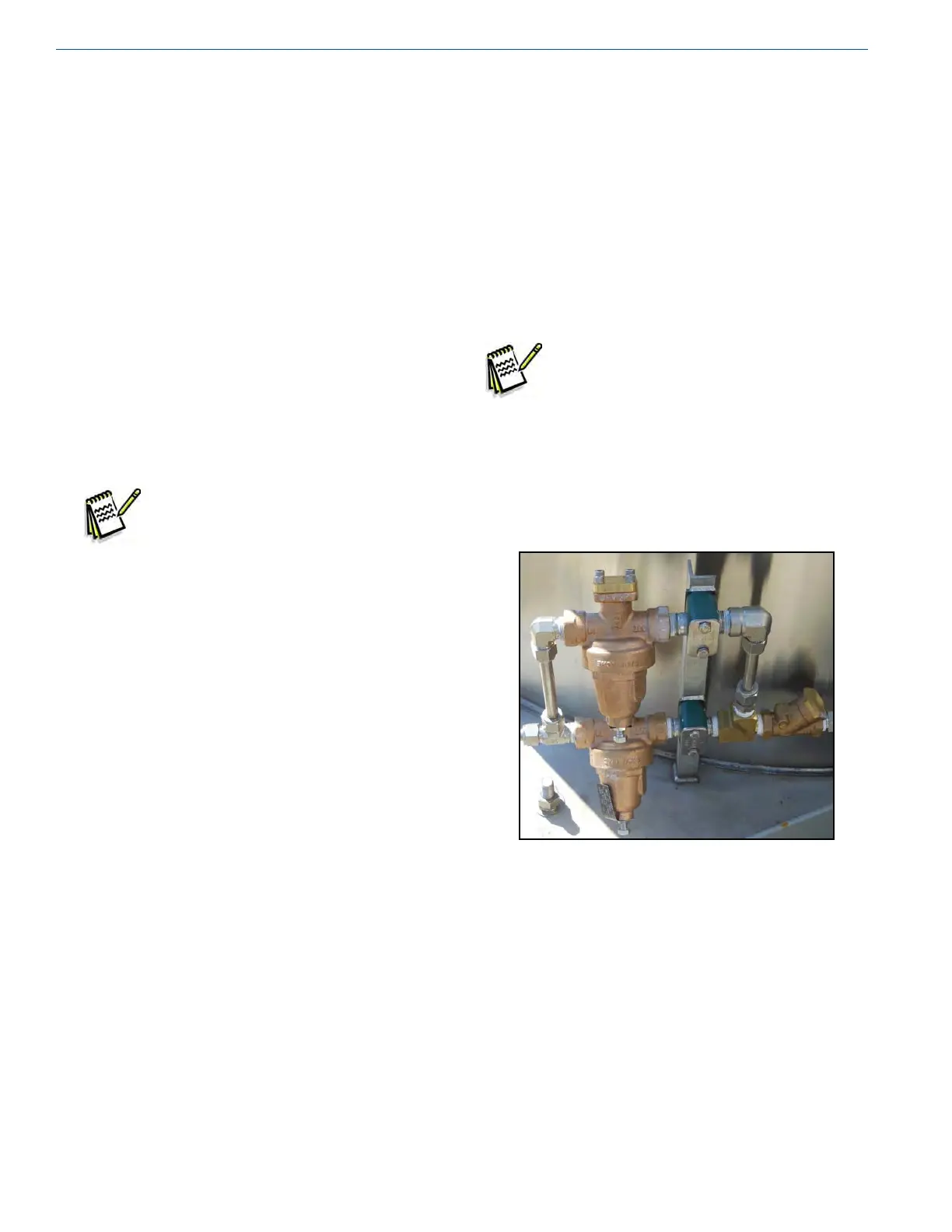

Note: Since all the liquid for both the PB and gas

use requirements of this model tank travels

through one regulator (R-1), the limiting

factor on ow is this regulator. A high

ow kit is offered for the 2000 and 3000

VHP tanks. This kit adds an additional PB

regulator in parallel with the existing PB

regulator (R-1) allowing for ows up to

3500 SCFH (see Photo 4).

Photo 4 - High Flow Kit

All other plumbing circuits that are covered on pages 9 and

10 of this manual also apply to the 2000 and 3000 VHP

Perma-Cyl models. These include the safety circuit, vent/

full trycock, high/low phase lines, liquid level gauges and

pressure gauges.

Loading...

Loading...