– 21 –

6. If two materials are press-fitted or laminated together, the gauge

will only measure the thickness of the sample that contacts the

probe.

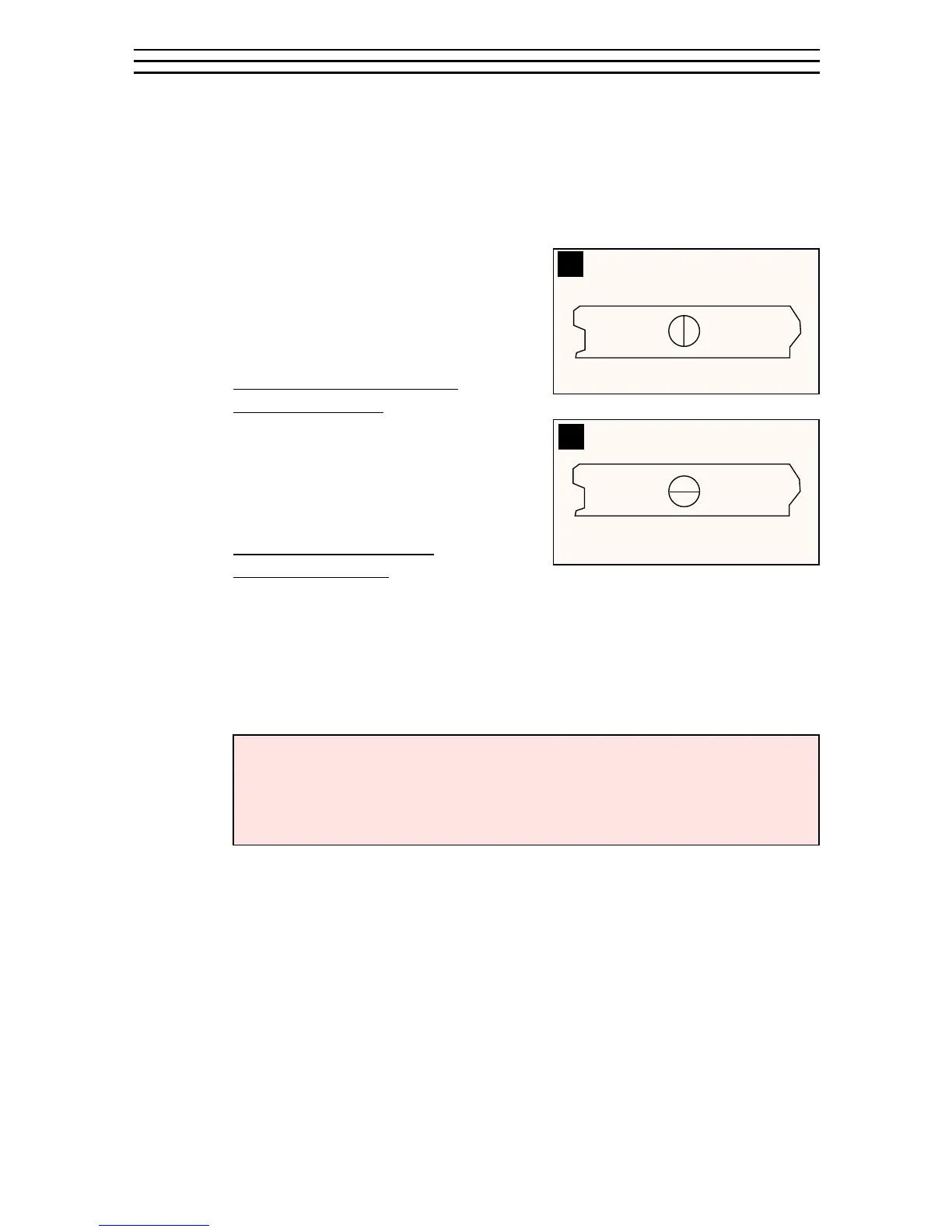

8.2Measurements Of Pipes Or Cylindrical Parts

When using the TI-25M to

measure the wall thickness of

a pipe, the orientation of the

probe is very important to obtain

accurate readings.

Pipe diameter is greater than

4 inches (100 mm):

Position the probe so the centerline of

the probe wearface is perpendicular to

the long axis of the pipe as shown in

illustration “A.”

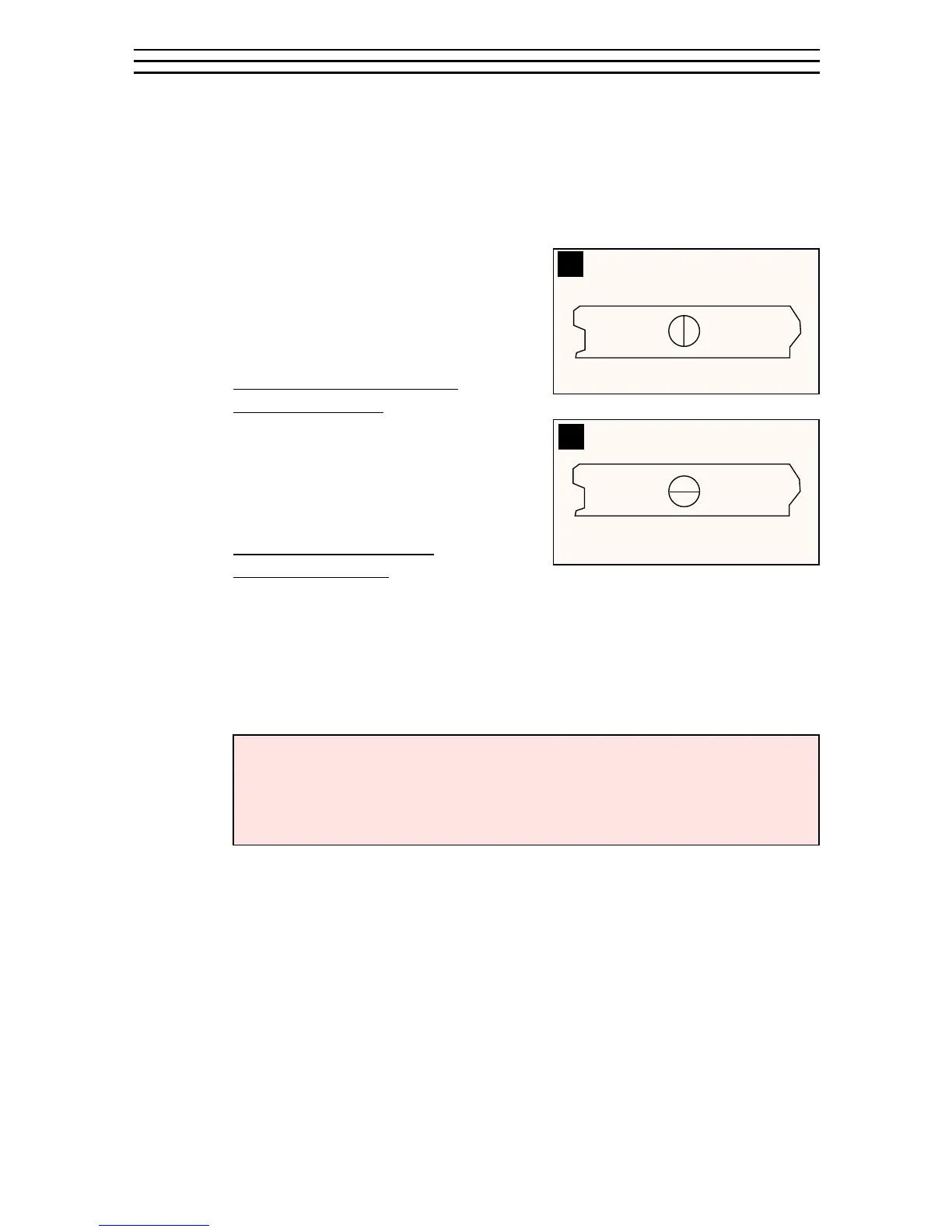

Pipe diameter is less than

4 inches (100 mm):

Two measurements should be performed at the same location, one with the

centerline of the probe perpendicular to the long axis and one parallel

(illustration “B”).

The smaller (thinner) of the two measurements should be used as the

actual wall thickness at the measurement location.

Additionally,on applications on pipe diameters less than 3 inches,

we recommend using the optional V-Block fixture which helps

maintain stable probe placement on the rounded measuring surface.

A

B

Parallel

Perpendicular

Loading...

Loading...