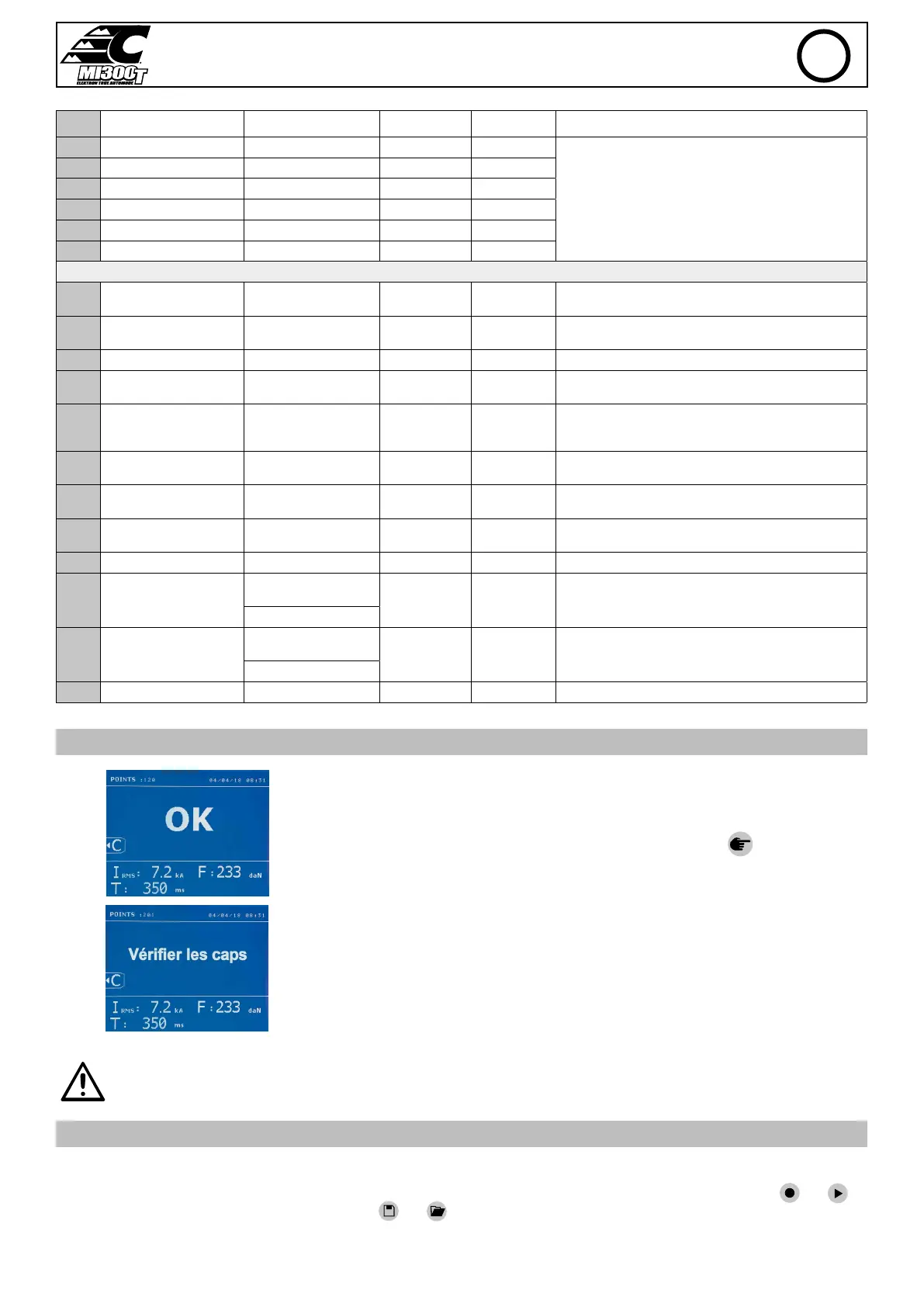

30

MI300T 220V

qj

12 CAPA voltage UPMCAPA = 0 V PASS No blocking

13 Voltage PM IGBT 1 and 2 UPMIGBT12 = xxx V PASS or FAIL Blocking

Problem controlling the power electronics, contact your

dealer.

14 Voltage PM IGBT 3 and 4 UPMIGBT34 = xxx V PASS or FAIL Blocking

15 IGBT test result 1 IGBT1 = xxx V PASS or FAIL Blocking

16 IGBT test result 2 IGBT2 = xxx V PASS or FAIL Blocking

17 IGBT test result 3 IGBT3 = xxx V PASS or FAIL Blocking

18 IGBT test result 4 IGBT4 = xxx V PASS or FAIL Blocking

Page CHECK n°2

1 Name of the product CONNEXION TRANSFO PASS or FAIL Blocking

Check the connection of the power cable from the gripper to

the generator.

2

Test result primary detec-

tion transfo

DATE/TIME PASS or FAIL No blocking

3 Date and time SHOW-ROOM ON or OFF No blocking

4 SHOW-ROOM mode

GGUN WELD SW =

x.xx V

PASS No blocking

5

Welding trigger, gun

trigger and gun tempera-

ture test

GGUN OPEN SW = x.xx V PASS or FAIL Blocking Check the connection of the power diode temperature sensor.

6

Trigger test on diode ope-

ning and temperature

TRANSFO TEMP = x.xx V ON or OFF Blocking

Overheating of the power transformer. Allow the machine to

cool down before starting up again.

7

Transformer primary

temperature

THICKNESS SENSOR =

xx.x mm

PASS No blocking

8 Position sensor

WELDING VOLTAGE =

x.xx V

PASS No blocking

9 Welding voltage BACKUP CELL = x.xx V PASS or FAIL No blocking

10 Backup battery voltage

AIR PRESSURE = xx.x

bar si PASS

PASS or FAIL Blocking Air pressure sensor from the HS network, contact your dealer.

Network pressure

11 Clamp pressure

GUN PRESSURE = xx.x

bar si PASS

PASS or FAIL Blocking Air pressure sensor of the HS gripper, contact your dealer.

Gun presence detection

12 Détection présence pistolet CONNEXION GUN ON or OFF No blocking

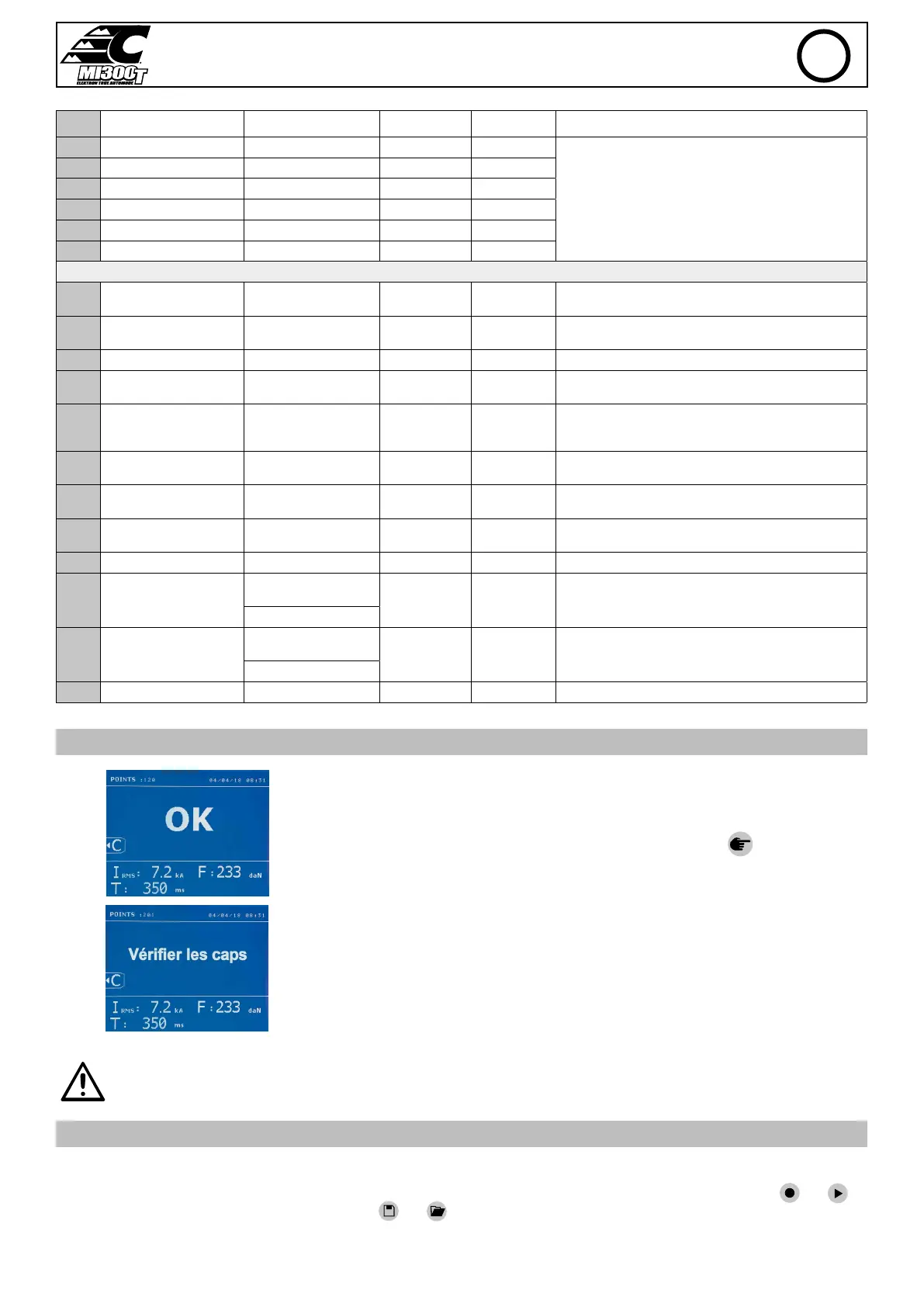

SPOT COUNT

A spot count tool keeps count of the dierent spot weld done using the same cap. If there is no

problem during the welding, the following message is displayed.

The count is displayed at the top left corner of the screen. Press the button

for 2 seconds to

reset the count after changing the caps.

The machine counts the number of points achieved with each arm independently. A warning

message appears on the screen when the limit of the points made by the headings is reached. The

message remains displayed after each point until the counter is reset.

If the caps are not changed after the warning message is displayed and the count is simply reset, they can deteriorate and have a negative

impact on the quality of the weld.

RECORDING FEATURES

The Identication mode is optional and can be activated using the «settings» menu.

If the identication mode is switched o, il sut de saisir un nom de rapport et de l’activer pour mémoriser les points de soudure eectués.

The log allows to store the parameters of the spots made using the clamp. It is available in all the modes by pressing the 2 buttons

and .

The user program is available in all modes by pressing the

and buttons.

EN

Loading...

Loading...