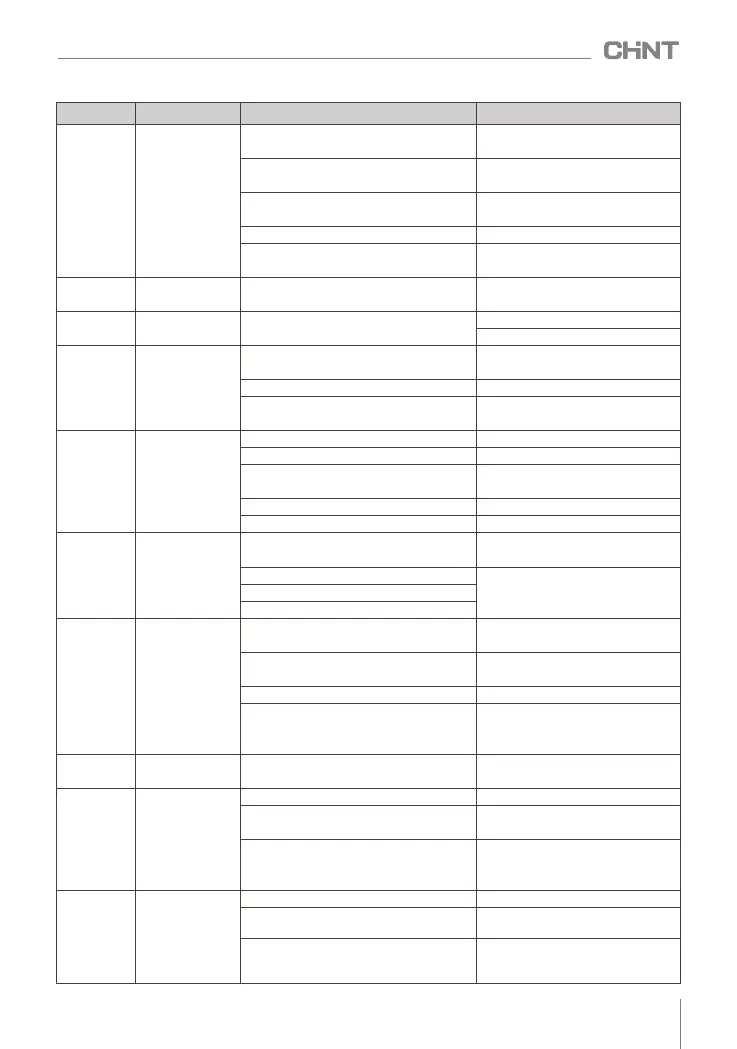

E.OL1

Motor overload

1. The motor overload protection coefficient

is not set correctly

Correctly set the motor overload

protection coefficient

2. The motor stalls or the sudden change of

load is too large

check load

3. Long-term low-speed and heavy-load

operation of general - purpose motors

Choose a dedicated motor

4. Grid voltage is too low Check grid voltage

5. The V/F curve is not suitable

Correctly set the V/F curve and torque

boost

E.EF

External device

failure

External fault emergency stop terminal is

valid

After the external fault is cancelled,

release the external fault terminal

E.EEP

Abnormal EEPROM

An error occurred while reading and writing

control parameters

STOP key reset

E.tE

Abnormal motor

self-learning

1. Motor nameplate parameter setting error

Correctly set the parameters

according to the motor nameplate

2. Perform reverse rotation self-tuning when

reverse rotation is prohibited

cancel prohibit reverse

3. Poor contact of motor connecting wire

Check motor wiring

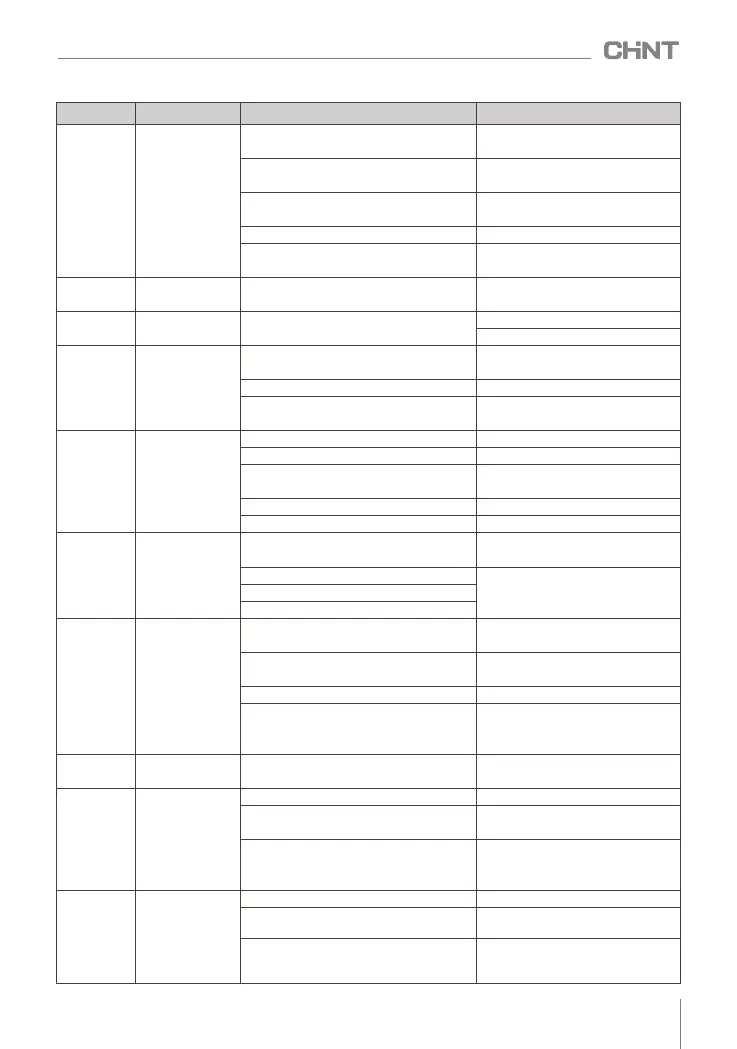

error code

Fault type

Possible cause of failure

Countermeasures

seek service

E.CE

abnormal

communication

1. The upper computer is not working

properly

Check the upper computer wiring

2. The communication line is abnormal Check the communication cable

3. The communication parameter setting is

incorrect

Correctly set communication

parameters

E.SHt

Abnormal

contactor

1. Grid voltage is too low Check grid voltage

2. The contactor is damaged

Replace the main circuit contactor

3. The power-on snubber resistor is

damaged

Replace snubber resistor

4. The control circuit is damaged

seek service

5. Input phase loss

Check input RST wiring

E.ItE

Abnormal current

detection circuit

1. The control board connection or plug-in

is loose

Check and rewire

2. The auxiliary power supply is damaged

seek service

3. The Hall device is damaged

4. The amplifier circuit is abnormal

4. Self - learning timeout

Check F0.08 ( operating frequency

upper limit ) to see if the set value of

F0.08 is lower than the rated frequency

E.Fb L

PID feedback lost

at runtime

PID feedback is less than FE .18 set value

Check the PID feedback signal or set

FE. 18 to a suitable value

E.OS

Motor Overspeed

Fault

1. The encoder parameter setting is incorrect

Correctly set the encoder parameters

2. No parameter identification

Carry out motor parameter

identification

3. Motor overspeed detection parameters

FE.20 , FE.21 settings are unreasonable

Set the detection parameters

reasonably according to the actual

situation

E . dEv

Excessive speed

deviation fault

1. The encoder parameter setting is incorrect

Correctly set the encoder parameters

2. No parameter identification

Carry out motor parameter

identification

3. The setting of detection parameters FE.22

and FE.23 for excessive motor speed

deviation is unreasonable

Set the detection parameters

reasonably according to the actual

situation

079

NVF2G-S Series Inverter User's Guide

Loading...

Loading...