56 • Maintenance Operating Manual Freeze Dryer ALPHA 1-2 LDplus

valve with warm water (max. +50°C). Finally it is necessary to wipe

the ice condenser chamber dry.

It is n o t

recommended to defrost the unit simply by leaving it at

room temperature over a long period of time. In this case the

tungsten wire reacts with the ambient atmosphere!

After defrosting and drying the unit, it is additionally recommended

to evacuate the unit for 30 minutes with o p e n

gas ballast valve.

All residues that may harm the tungsten wire are removed in this

way.

7.3.2. Replacement and adjustment

The vacuum sensor has to be replaced if “---“ is shown in the

vacuum field after the aeration of the system instead of “Atm” and

if the process and equipment information window shows the

message “Vacuum sensor defective”. If after the warm-up phase

and the aeration of the unit the vacuum display still does not show

“Atm” but a value equal to or smaller than 900 mbar, the vacuum

sensor has to be readjusted. The warm-up phase of the vacuum

sensor takes at least 5 minutes.

7.3.2.1. Vacuum sensor adjustment

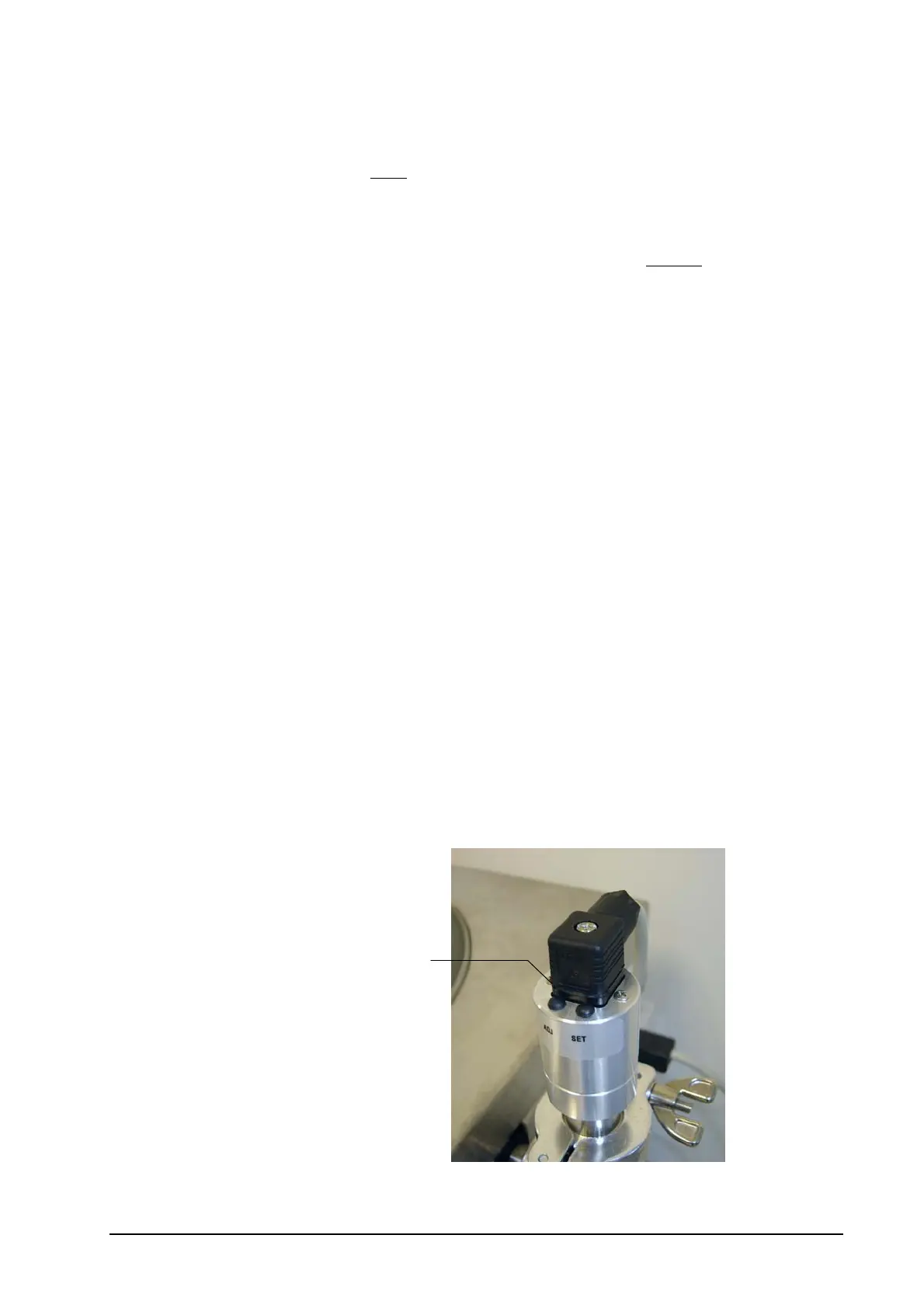

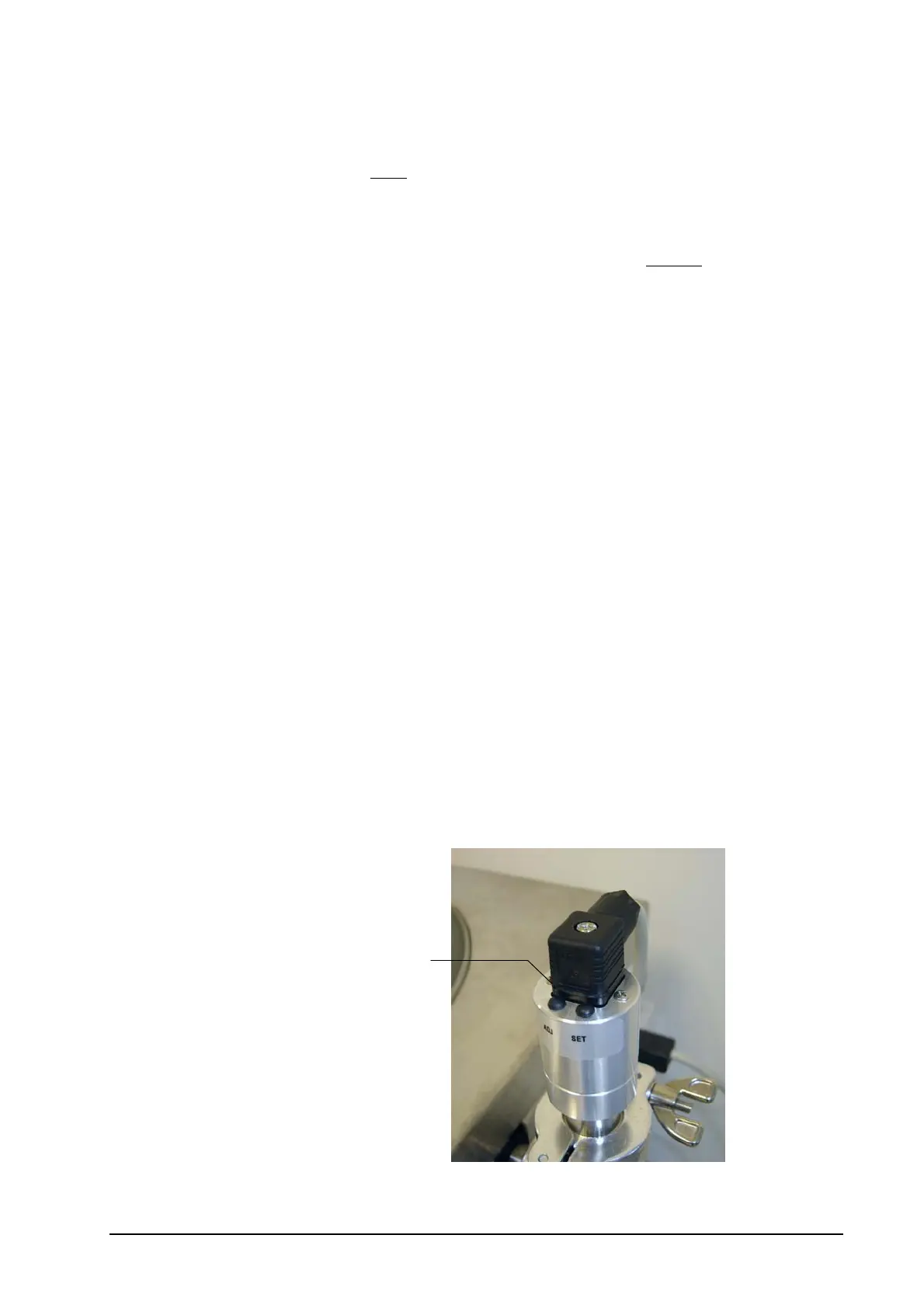

The vacuum sensor has two adjustment buttons labelled “adj” and

“set”. The buttons are protected by protective caps. Remove the

protective caps of the buttons prior to adjusting the sensor. Use a

small pen (max. ∅ 2.5mm) to actuate the buttons. Refit the

protective caps after the adjustment.

A digital readjustment to atmospheric pressure (Atm) and zero is

possible directly at the vacuum sensor using the button labelled

“adj” (adjust). The measuring transducer automatically recognises

the adjustment point. If a zero adjustment has to be performed, the

actual pressure should be smaller than 5.0x10

-5

mbar (factory

setting). Alternatively, the sensor can also be adjusted to a

reference value (see below). We recommend a warm-up phase of

at least 5 minutes before the adjustment.

Buttons with protective caps

for adjusting the senso

Loading...

Loading...