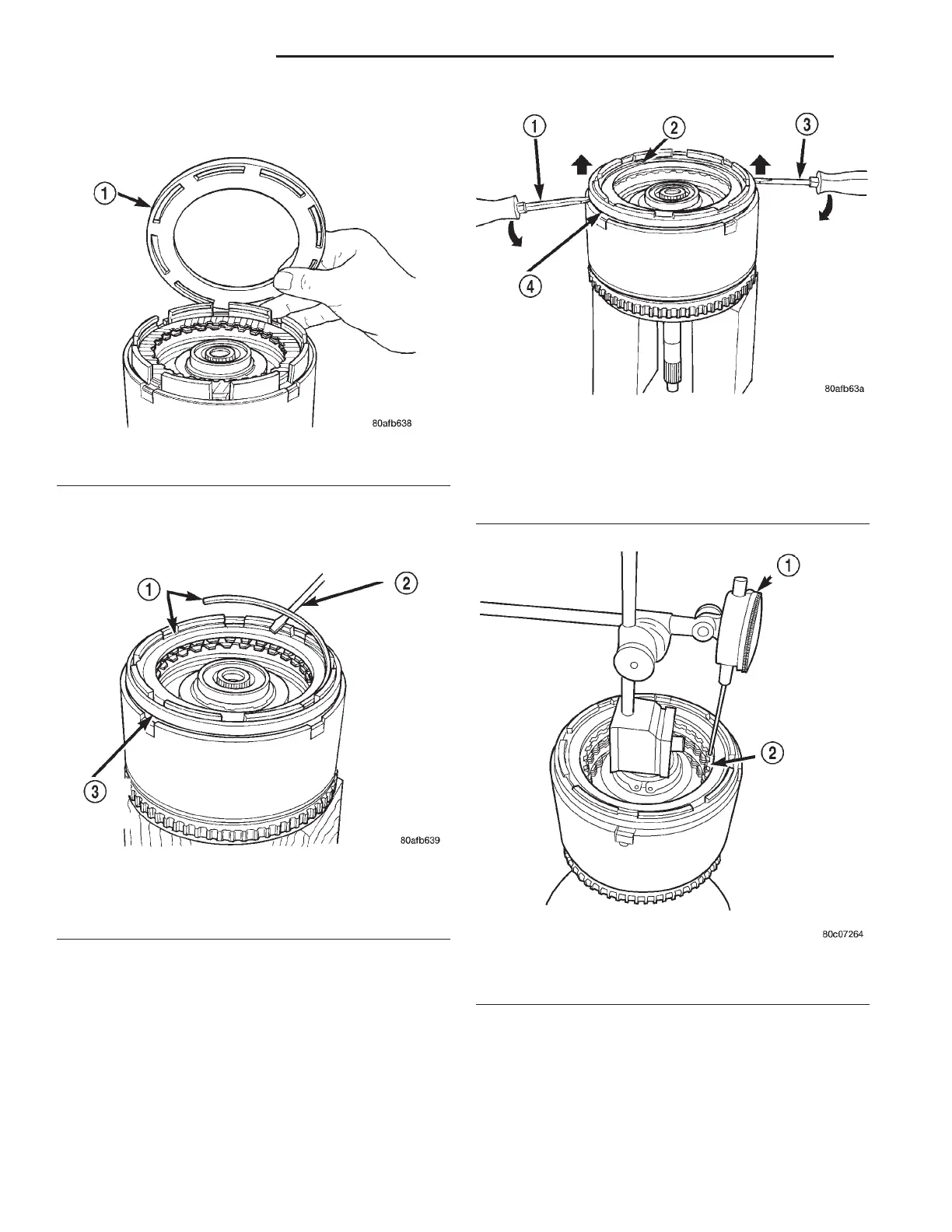

(29) Install reverse clutch reaction plate with the

flat side down towards reverse clutch (Fig. 280).

(30) Tap reaction plate down to allow installation

of the reverse clutch snap ring. Install reverse clutch

snap ring (Fig. 281).

(31) Pry up reverse reaction plate to seat against

snap ring (Fig. 282).

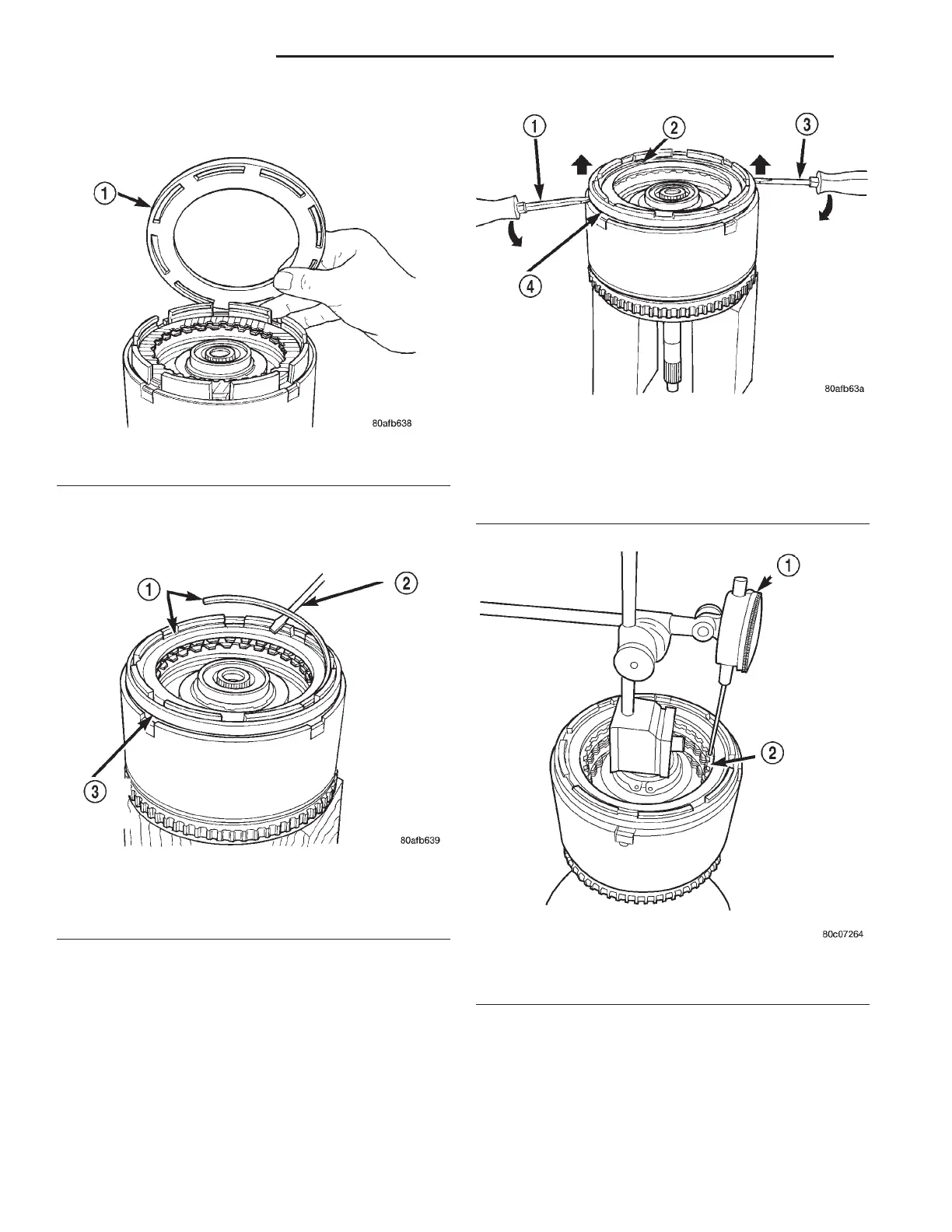

(32) Set up a dial indicator on the reverse clutch

pack as shown in (Fig. 283).

(33) Using moderate pressure, press down and

hold (near indicator) reverse clutch disc with screw-

driver or suitable tool and zero dial indicator (Fig.

284). When releasing pressure, indicator should

advance 0.005-0.010. as clutch pack relaxes.

(34) Apply 30 psi (206 kPa) air pressure to the

reverse clutch hose on Tool 8391. Measure and record

reverse clutch pack measurement in four (4) places,

90° apart.

(35) Take average of four measurements and com-

pare with reverse clutch pack clearance specification.

The reverse clutch pack clearance is 0.89-1.37

mm (0.035-0.054 in.). Select the proper reverse

clutch snap ring to achieve specifications:

Fig. 280 Install Reaction Plate

1 – REVERSE CLUTCH REACTION PLATE (FLAT SIDE DOWN)

Fig. 281 Install Reverse Clutch Snap Ring

1 – REVERSE CLUTCH SNAP RING (SELECT)

2 – SCREWDRIVER

3 – REVERSE CLUTCH REACTION PLATE

Fig. 282 Pry Up Reaction Plate to Seat Against Snap

Ring

1 – SCREWDRIVER

2 – SNAP RING

3 – SCREWDRIVER

4 – MUST RAISE REVERSE REACTION PLATE TO RAISE SNAP

RING

Fig. 283 Measure Reverse Clutch Pack Clearance

1 – DIAL INDICATOR

2 – REVERSE CLUTCH

21 - 98 42LE TRANSAXLE LH

DISASSEMBLY AND ASSEMBLY (Continued)

Loading...

Loading...