Support special tool P-334 on press table so that

pinion head of transfer shaft can be pressed through

table (Fig. 388).

ASSEMBLE AND BEARING ADJUSTMENT

PROCEDURE

The following steps will determine the correct shim

thickness required to obtain proper pinion depth. All

special tools described in this procedure must be

used to obtain correct results.

CAUTION: Failure to adjust pinion depth correctly

could cause gear noise or transaxle failure.

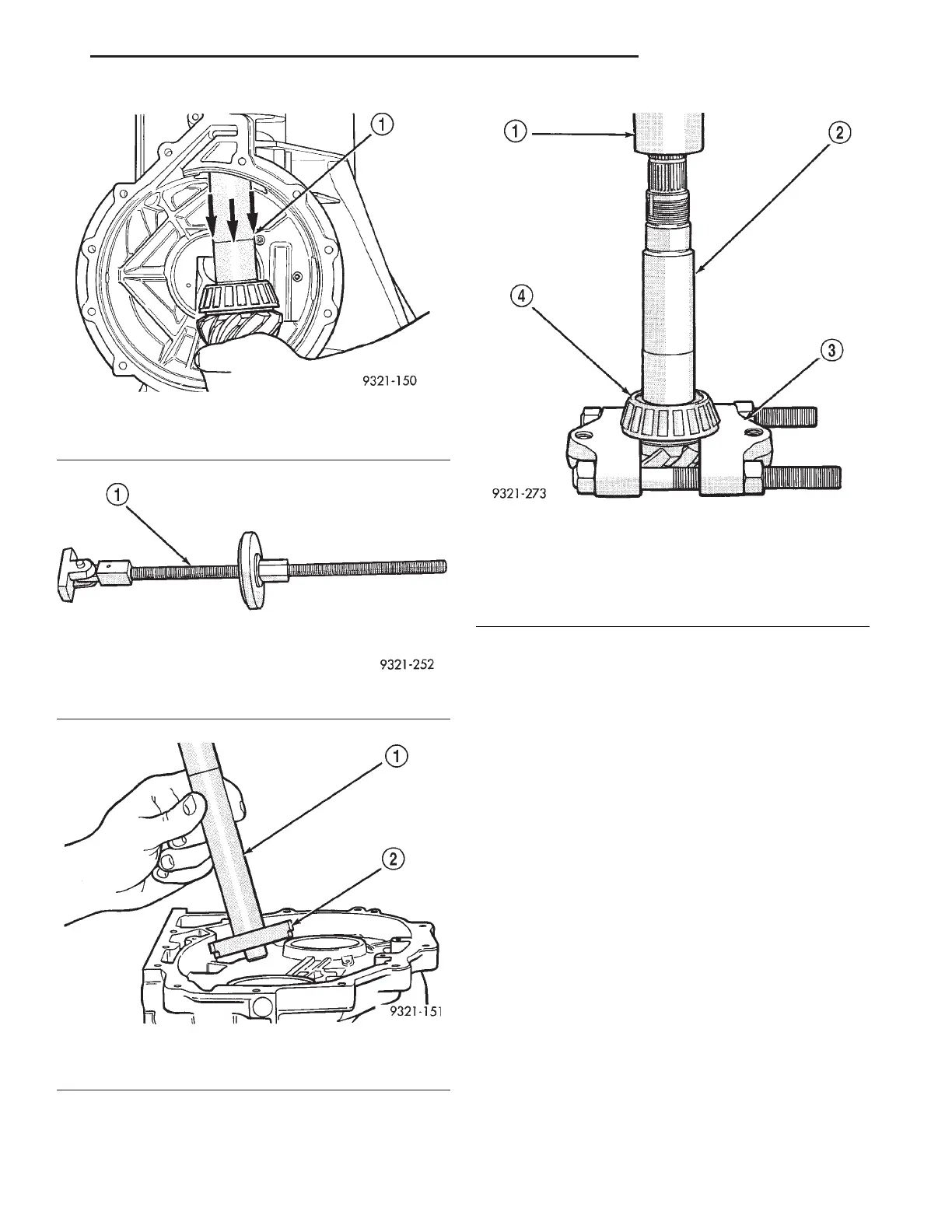

(1) Install front transfer shaft bearing cup (Fig.

389). The transfer shaft bearing cup must be

installed before making pinion depth measurement.

Use special tool 6494 to install bearing cup. There

are no shims located behind this bearing cup.

CAUTION: The bearing cup is seated in the case

correctly if there is no clearance between the bot-

tom of the bearing cup and case. If a 0.001” or

0.002” feeler gauge does not fit, the bearing cup is

completely seated into transaxle case.

(2) Install centering block (special tool 6549-2) into

the transaxle case (Fig. 390). Screw centering block

into inner adjuster hole of case until it bottoms. The

pegs on the special tool are only used for installation.

Orientation with in the case is not required.

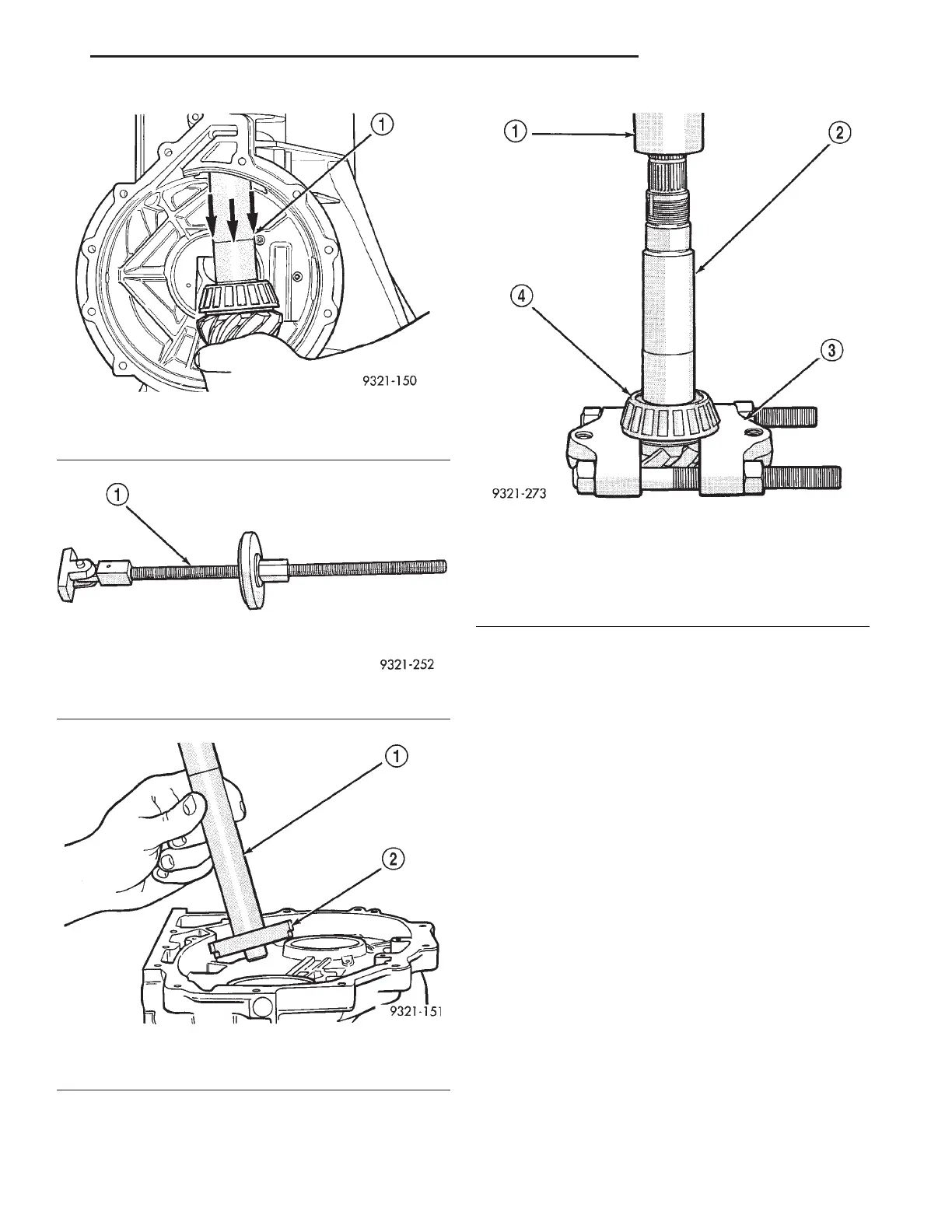

Fig. 385 Remove Transfer Shaft Assembly From

Case

1 – TRANSFER SHAFT

Fig. 386 Transfer Shaft Seal Remover

1 – SPECIAL TOOL 6310

Fig. 387 Front Transfer Shaft Cup Removal

1 – SPECIAL TOOL C-4171

2 – SPECIAL TOOL 6495

Fig. 388 Remove Front Transfer Shaft Bearing And

Pinion Depth Shim

1 – ARBOR PRESS

2 – TRANSFER SHAFT

3 – SPECIAL TOOL P-334

4 – FRONT TRANSFER SHAFT BEARING

LH 42LE TRANSAXLE 21 - 125

DISASSEMBLY AND ASSEMBLY (Continued)

Loading...

Loading...