(48) If the carrier requires reconditioning, refer to

Differential Carrier Recondition.

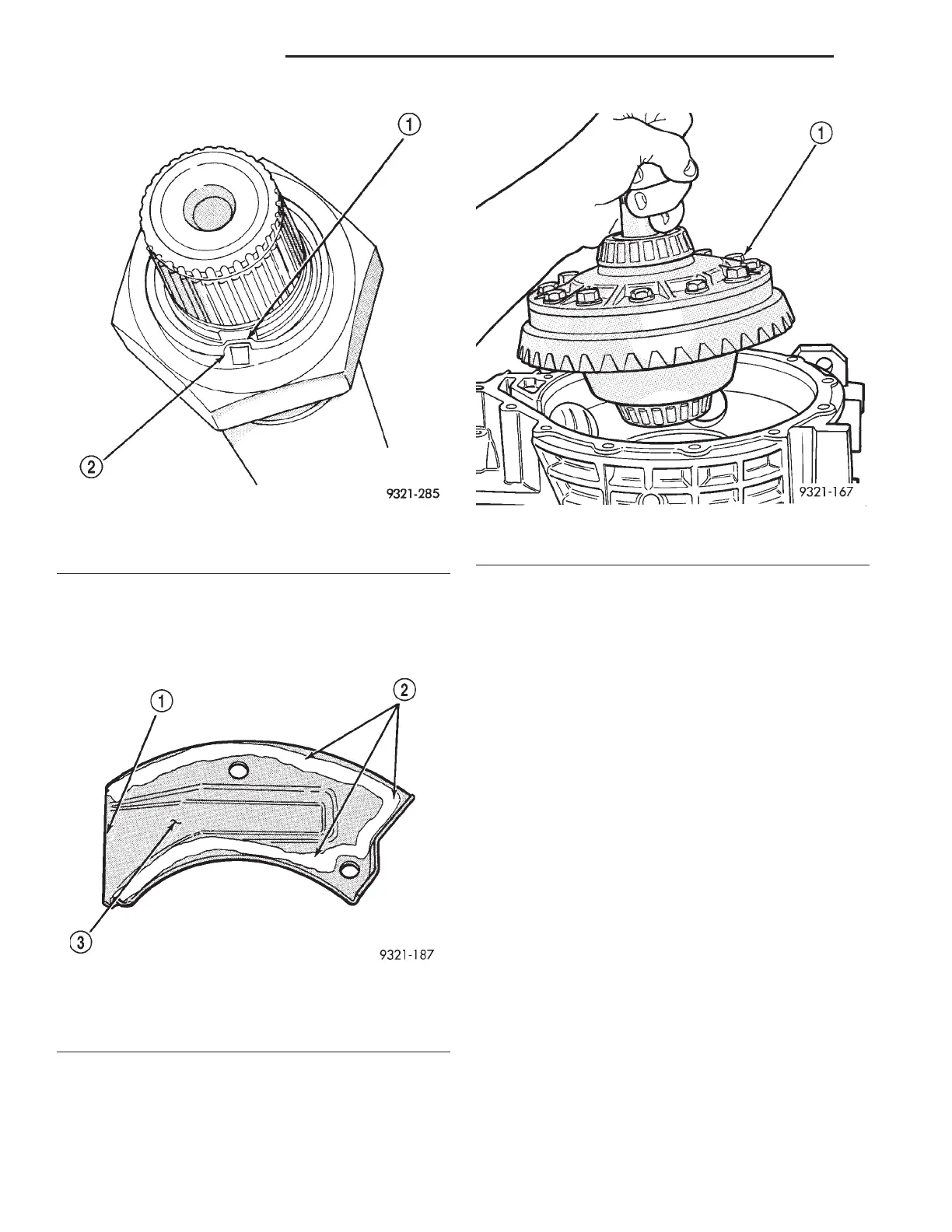

(49) Install vent baffle. Apply sealer as shown in

(Fig. 424).

(50) Install new inner adjuster O-ring. Lube inner

adjuster threads and O-ring. Then install inner

adjuster flush with differential side of case.

(51) Install differential assembly (with ring gear

attached) into transaxle case (Fig. 425).

(52) Transfer shaft to ring gear backlash should be

0.006” to 0.0099 thousands of an inch. To get the

backlash close enough to measure, perform the fol-

lowing steps. Hold the transfer shaft with one hand

and rock the ring gear back and forth (Fig. 426). You

should feel some backlash between the gears. If no

backlash is felt use special tool 6502B to turn the

inner adjuster so that it raises the differential

assembly. This will increase backlash. If there is to

much backlash, use special tool 6502B to turn the

inner adjuster so that it lowers the differential

assembly. This will decrease backlash. Recheck the

backlash after each adjustment.

(53) Apply a 1/8 inch bead of sealant to differential

cover flange. Then install differential cover with seal-

ant (Fig. 427) and tighten cover bolts.

(54) Install seal protector (special tool 6591) on

shaft (Fig. 428).

CAUTION: Lube threads and O-ring on adjuster

before installing. Failure to due so will result in

thread damage to the adjuster and differential

cover.

(55) Install outer adjuster with new O-ring (Fig.

429). Torque the outer adjuster (special tool 6503) to

the torque reading recorded in Step 30. Then seat

bearings by turning differential three or four revolu-

tions in both directions. Tighten adjuster a second

time to same torque recorded in Step 30. Again

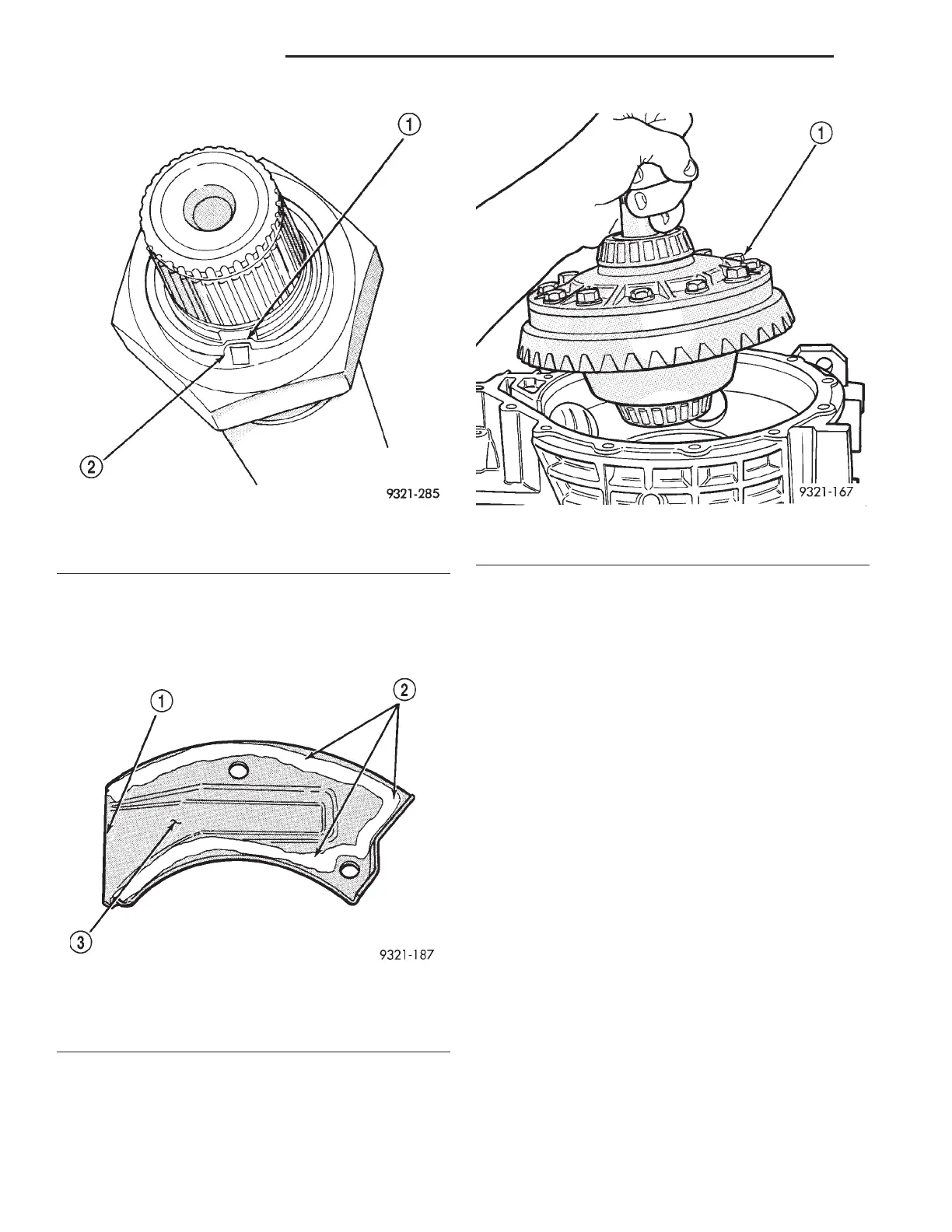

Fig. 423 Correctly Staked Nut

1 – BOTTOMED IN SLOT

2 – CORRECTLY STAKED NUT

Fig. 424 Baffle Installation

1 – NO SEALER ON THIS EDGE

2 – APPLY SEALER

3 – VENT BAFFLE

Fig. 425 Differential Assembly Installation

1 – DIFFERENTIAL ASSEMBLY

21 - 136 42LE TRANSAXLE LH

DISASSEMBLY AND ASSEMBLY (Continued)

Loading...

Loading...