should be 0.5 to 1.3 N·m (5 to 12 in. lbs.). If the turn-

ing torque is too high, install a thicker transfer shaft

preload shim. If the turning torque is too low, install

a thinner transfer shaft preload shim.

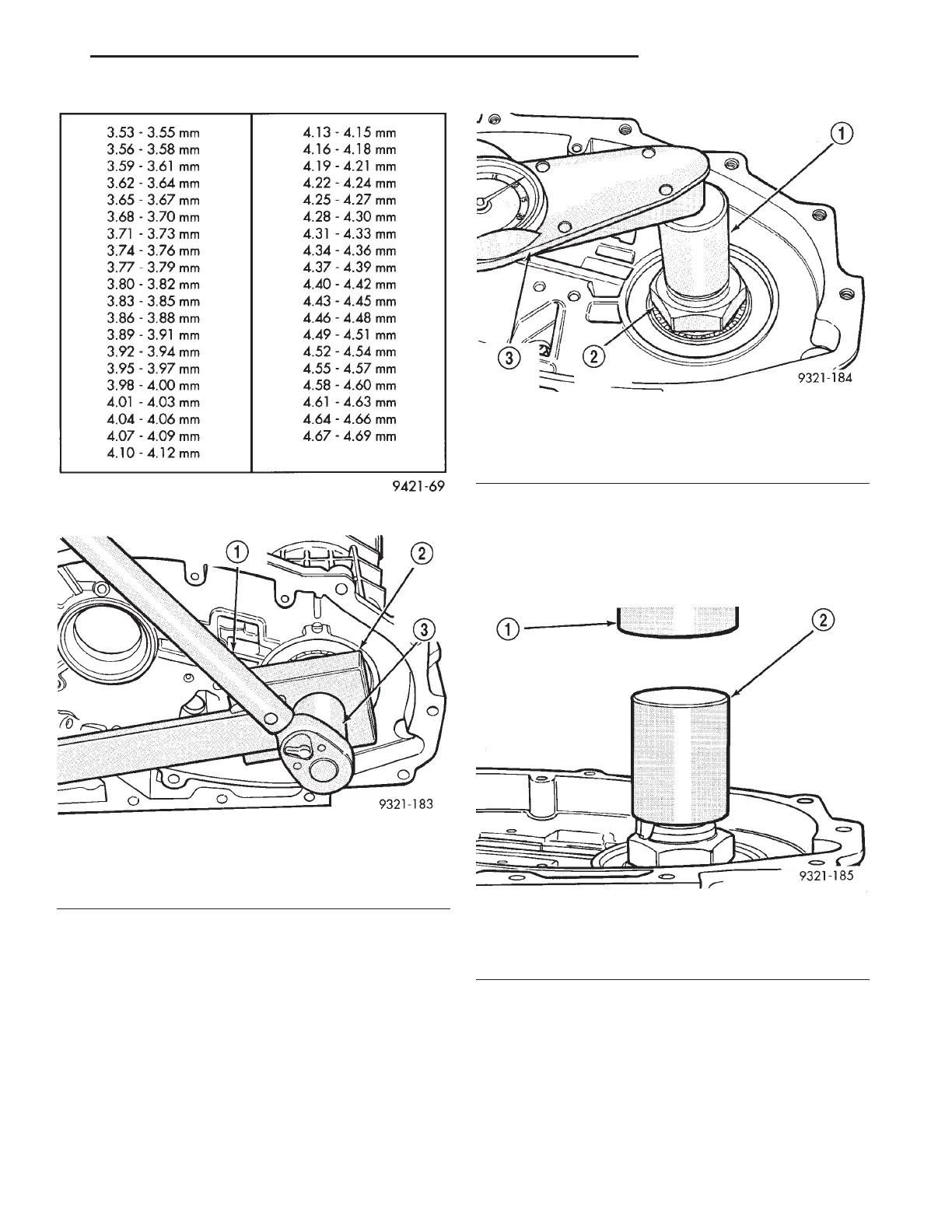

CAUTION: A press and special tool 6589 must be

used when staking the transfer shaft nut. Do not use

a hammer and the special tool to stake nut. If a ham-

mer is used; seal, bearing, and/or tool damage may

result. Also the stake will not be seated against the

shaft correctly. This will allow the nut to loosen.

(46) After the correct turning torque is obtained,

use special tool 6589 to stake the new transfer shaft

nut (Fig. 422). Be sure that the tool arms line up

with slots in the transfer shaft. Use a press with the

special tool to make the stakes in the nut.

CAUTION: Failure to stake the transfer shaft nut

correctly may allow the nut to loosen during tran-

saxle operation. This will cause transaxle failure.

(47) At this point the transfer shaft, new oil seals,

pinion depth and transfer shaft preload have been

set. The following steps will set the backlash between

the transfer shaft and the ring gear.

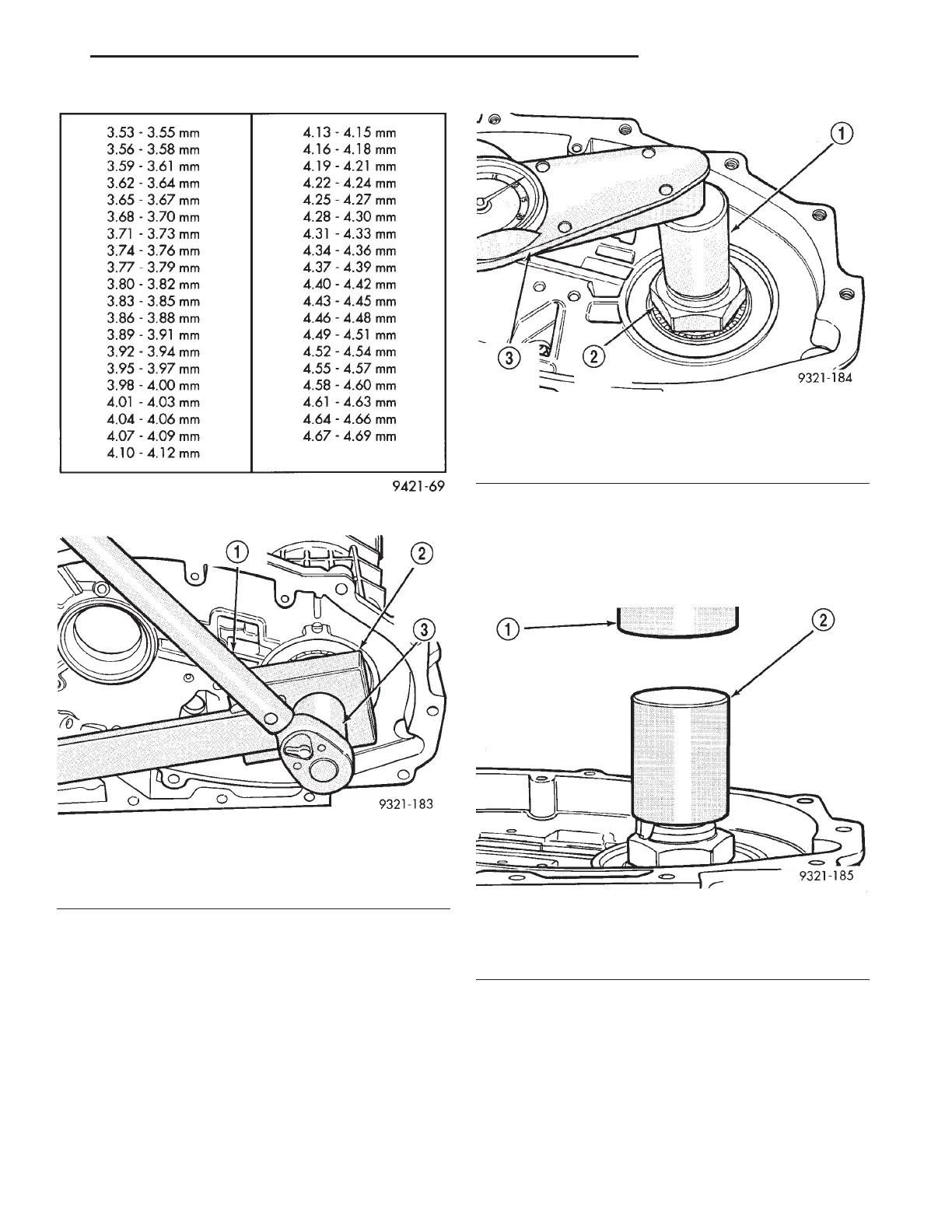

Transfer Shaft Rear Shim Chart

Fig. 420 Transfer Shaft Nut Installation

1 – TORQUE WRENCH

2 – HOLDER (6497)

3 – SHAFT SOCKET (6498)

Fig. 421 Checking Turning Torque

1 – SOCKET (6498)

2 – TRANSFER SHAFT NUT

3 – IN. LBS. TORQUE WRENCH

Fig. 422 Staking New Nuts

1 – ARBOR PRESS

2 – STAKING TOOL

(6589)

LH 42LE TRANSAXLE 21 - 135

DISASSEMBLY AND ASSEMBLY (Continued)

Loading...

Loading...