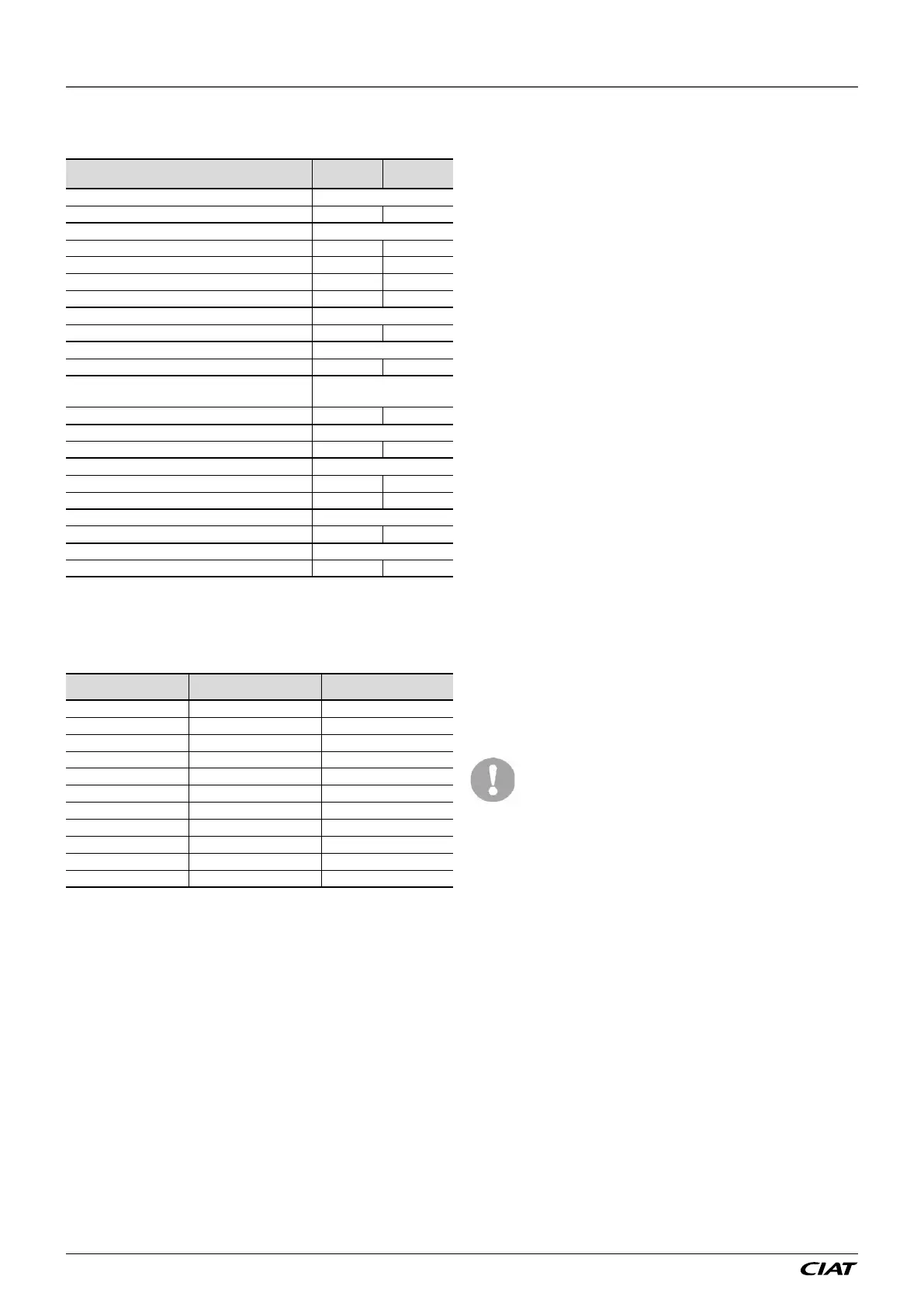

14.4 - Tightening torques for the main

electrical screw connections

Screw type

Designation

in the unit

Torque (N∙m)

Soldered screw (PE) customer connection

M8 PE 80

Screw on switch inlet zones

Switch 3LD2114-0TK51 QS_ 2-2,5

Switch 3LD2214-0TK51 2-2,5

Switch 3LD2514-0TK51 2,5-3

Switch 3LD2714-0TK51 2,5-3

Tunnel terminal screw, compressor protection

Fuse 3NW6120-1 QM

(1)

1,2

Tunnel terminal screw, compressor contactor

Contactor 3RT1034-2AB00 KM

(1)

3-4,5

Tunnel terminal screw, fan, heater, pump

protection

Disconnect switch 3RV1011-1BA10 QM

(1)

0,8-1,2

Tunnel terminal screw, heater relay

Relay 3RH1122-2AB00 KM

(1)

0,8-1,2

Tunnel terminal screw, auxiliary contact

Auxiliary terminal block 3RH1911-2FA11 - 0,8-1,2

Auxiliary terminal block 3RH1921-2FA22

Tunnel terminal screw, control power transformer

Transformer 4AM3496-0FS30-0EN1 TC 0,8-1,2

Compressor earth terminal

M8 Gnd 12

(1) The spring-loaded terminal connections are designed to ensure permanent

afxture on the conductor.

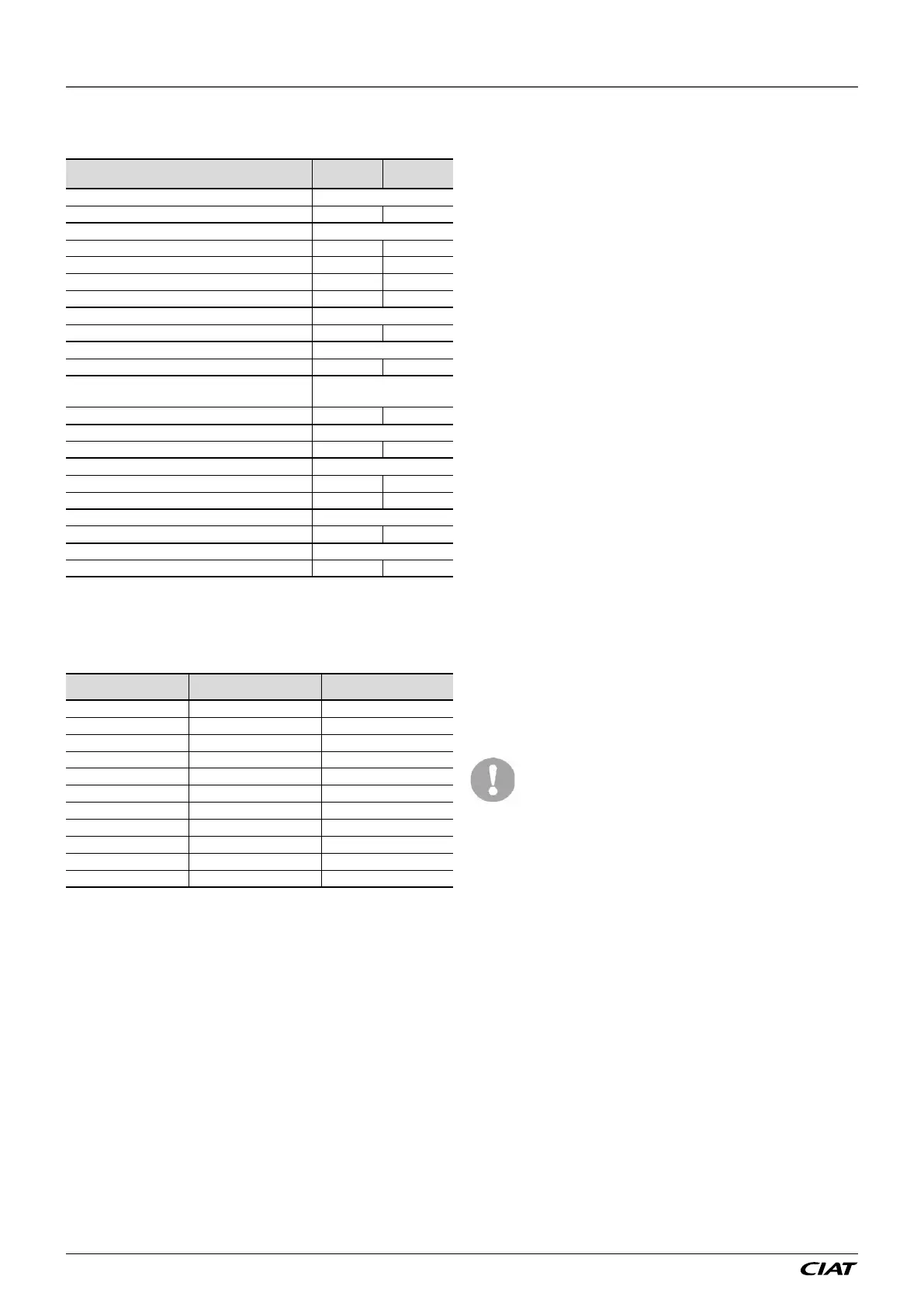

14.5 - Tightening torques for the main bolts

and screws

Screw type Used for Torque (N∙m)

Compressor strut Compressor support 30

M8 nut BPHE

(1)

xing 15

M10 nut Compressor mounting 30

M16 nut Compressor xing 30

Oil nut Oil equalisation line 75

Taptite screw M6 Fan support 7

Taptite screw M8 Fan motor xing 13

H M8 screw Fan scroll xing 18

Metal screw Sheet metal plates 4,2

H M6 screw Stauff clamps 10

Earth screw Compressor 2,8

(1) BPHE = Brazed plate heat exchanger

14.6 - Evaporator coil

We recommend, that nned coils are inspected regularly to check

the degree of fouling. This depends on the environment where

the unit is installed, and will be worse in urban and industrial

installations and near trees that shed their leaves.

For coil cleaning, two maintenance levels are used, based on

the AFNOR X60-010 standard:

Level 1

- If the evaporator coils are fouled, clean them gently in a vertical

direction, using a brush.

- Only work on air evaporators with the fans switched off.

- For this type of operation switch off the heat pump if service

considerations allow this.

- Clean evaporators guarantee optimal operation of your unit.

Cleaning is necessary when the evaporators begin to become

fouled. The frequency of cleaning depends on the season and

location of the unit (venti-lated, wooded, dusty area, etc.).

Level 2

The two cleaning products can be used for any Cu/Al coil with

protection.

Clean the coil, using appropriate products.

We recommend TOTALINE products for coil cleaning:

Part No. P902 DT 05EE: traditional cleaning method

Part No. P902 CL 05EE: cleaning and degreasing.

These products have a neutral pH value, do not contain

phosphates, are not harmful to the human body, and can be

disposed of through the public drainage system.

Depending on the degree of fouling both products can be used

diluted or undiluted.

For normal maintenance routines we recommend using 1 kg of

the concentrated product, diluted to 10%, to treat a coil surface

of 2 m2. This process can either be carried out using a high-

pressure spray gun in the low-pressure position.

With pressurised cleaning methods care should be taken not to

damage the coil ns. The spraying of the coil must be done:

- in the direction of the ns

- in the opposite direction of the air ow direction

- with a large diffuser (25-30°)

- at a minimum distance of 300 mm from the coil.

It is not necessary to rinse the coil, as the products used are pH

neutral. To ensure that the coil is perfectly clean, we recommend

rinsing with a low water ow rate. The pH value of the water used

should be between 7 and 8.

Never use pressurised water without a large

diffuser. Do not use high-pressure cleaners for Cu/

Al coils.

Concentrated and/or rotating water jets are strictly

forbidden. Never use a uid with a temperature

above 45°C to clean the air heat exchangers.

Correct and frequent cleaning (approximately every

three months) will prevent 2/3 of the corrosion

problems.

Protect the control box during cleaning operations.

14.7 - Condenser maintenance

Check that:

- the insulating foam is intact and securely in place.

- the cooler heaters are operating, secure and correctly

positioned.

- the water-side connections are clean and show no sign of

leakage.

14 - STANDARD MAINTENANCE

AQUACIAT

CALÉO™

TD EN-36

Loading...

Loading...