Manual 0-5406 4-3 OPERATION

4T (Latch Mode)

This mode of welding is mainly used for long welding runs to reduce operator fatigue. In this mode the opera-

tor can press and release the torch trigger and the output will remain active. To deactivate the power source,

the trigger switch must again be depressed and realised, thus eliminating the need for the operator to hold

the torch trigger.

NOTE

(Optional) Foot Control will not work properly in 4T mode and should not be used in this mode.

Note: If Triggerswitch is released

duringthe Downslope time then

weld current ceases and Postflow

time begins.

.

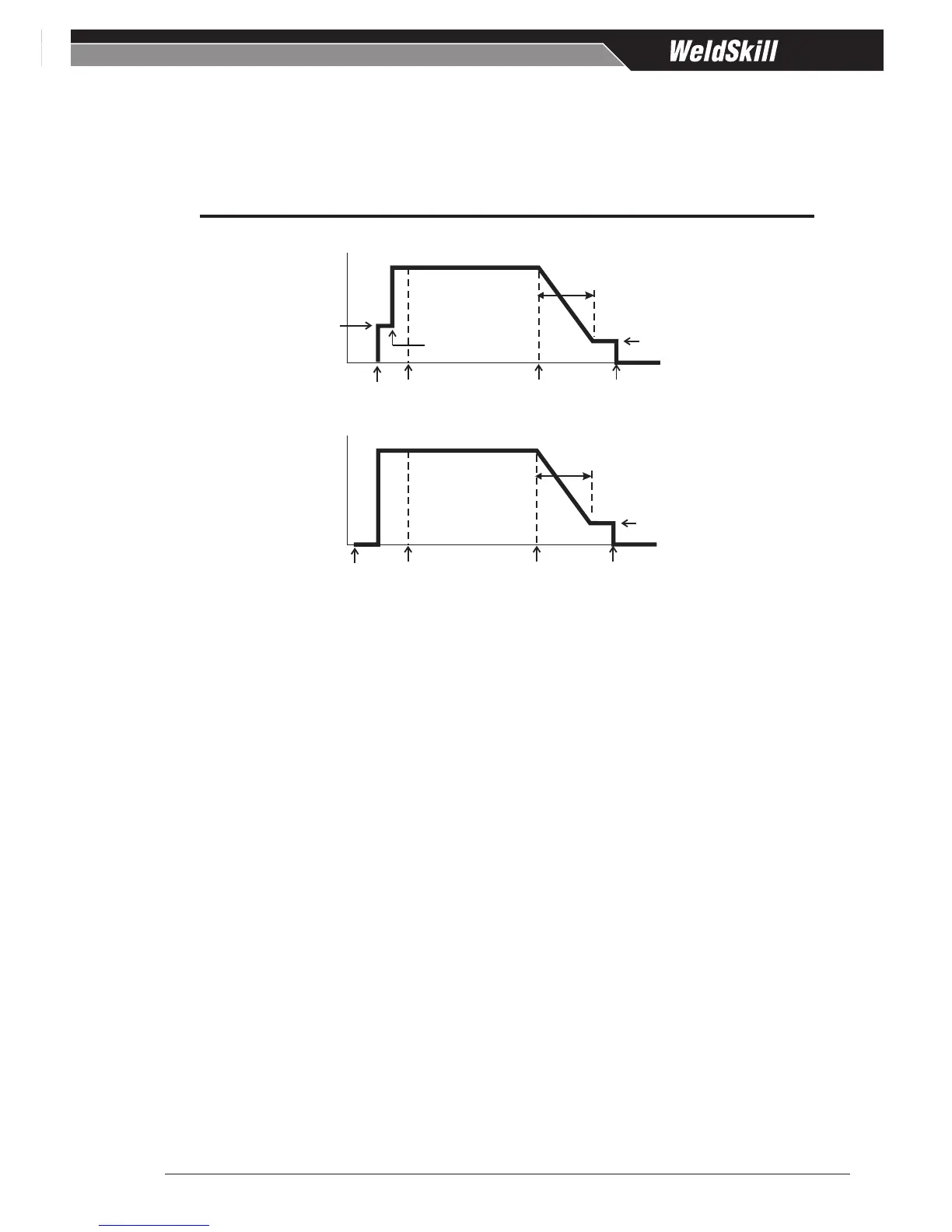

Figure 4-3: 4T Timing Sequence

Note that when operating in GTAW (LIFT TIG & HF TIG modes), the power source will remain activated until

the selected down slope time has elapsed. At any time whilst in 4T Mode if the TIG Torch Trigger Switch is

depressed and released welding will cease immediately.

6. Arc Force/Down Slope Control

Arc Force Feature (Not Shown)

This feature operates in Stick (Manual Arc) mode.

Stick electrodes can sometimes ‘stick’ to the work piece when pushed into a tight corner or joint fit-up with

particular stick electrodes. The Arc force feature can be particularly beneficial in helping to overcome this by

automatically increasing current when the machine senses a decrease in voltage levels. with particular elec-

trodes. In general increasing the Arc Force control toward '10' (maximum Arc Force) allows greater penetration

control to be achieved.

Down Slope

Downslope is used to set the time for weld current to ramp down.

Note: When using an (optional) Foot Control it is recommended that the downslope control is turned to 0

(minimum) and downslope is controlled manually by the Foot Control.

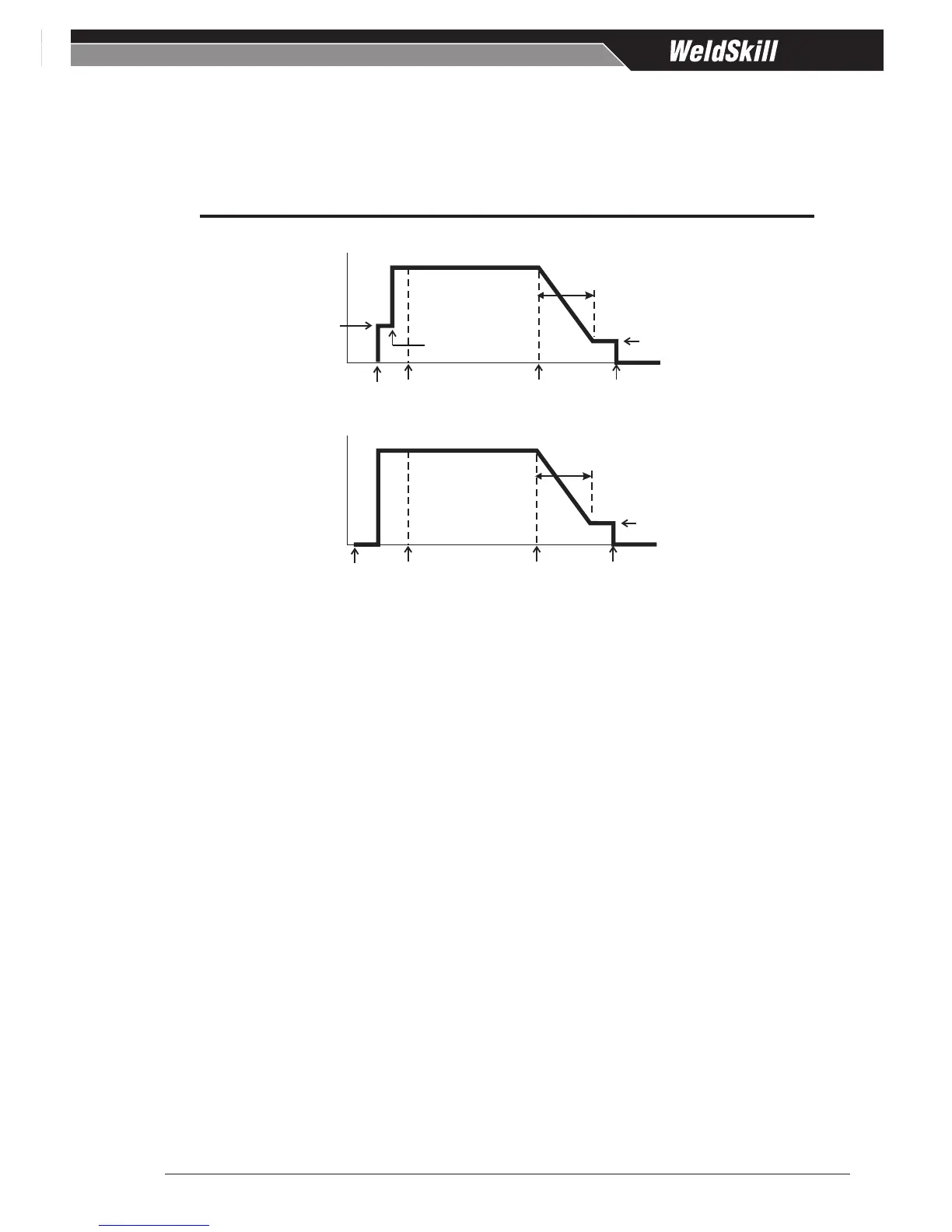

Down Slope in 2T (Normal Mode)

Whilst welding if the TIG Torch Trigger Switch is released, the welding current ramps down to zero current

over a defined period of time. The time period is determined by the setting of the Downslope Control Knob.

Downslope Range is 0 to 10 seconds.

Loading...

Loading...