8

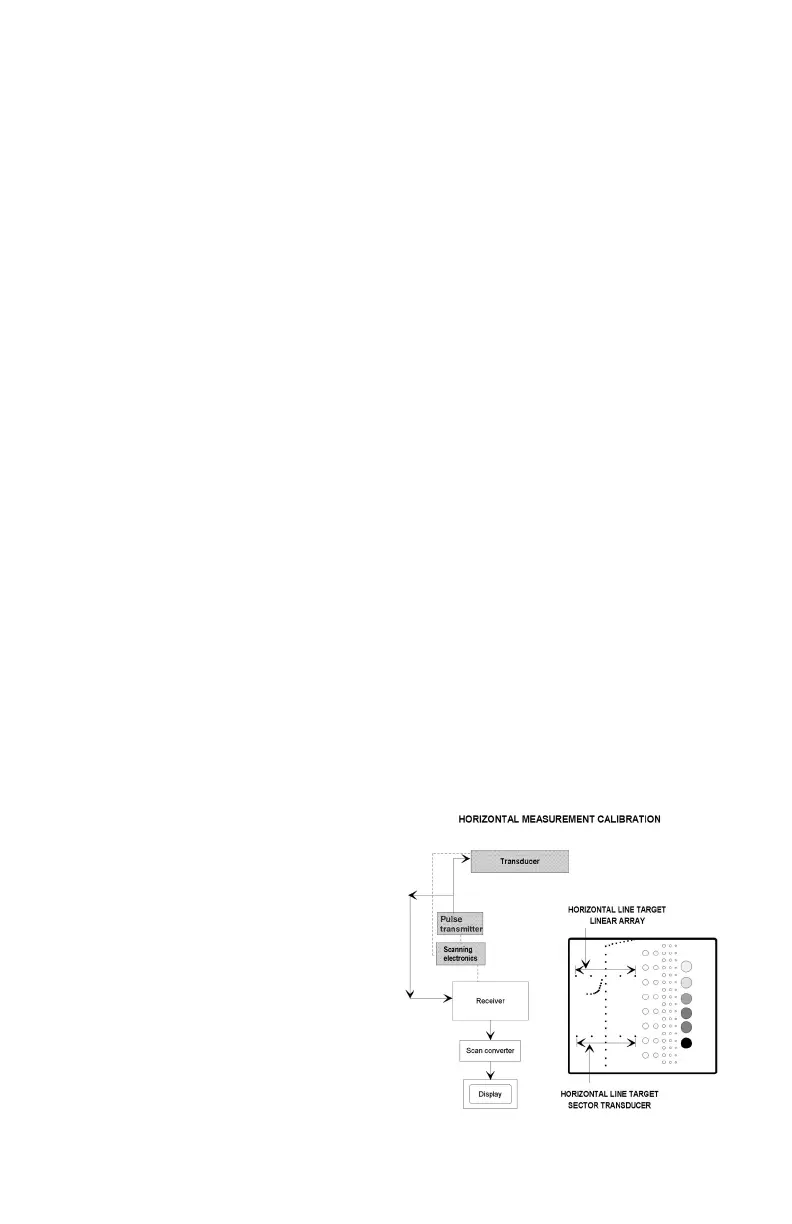

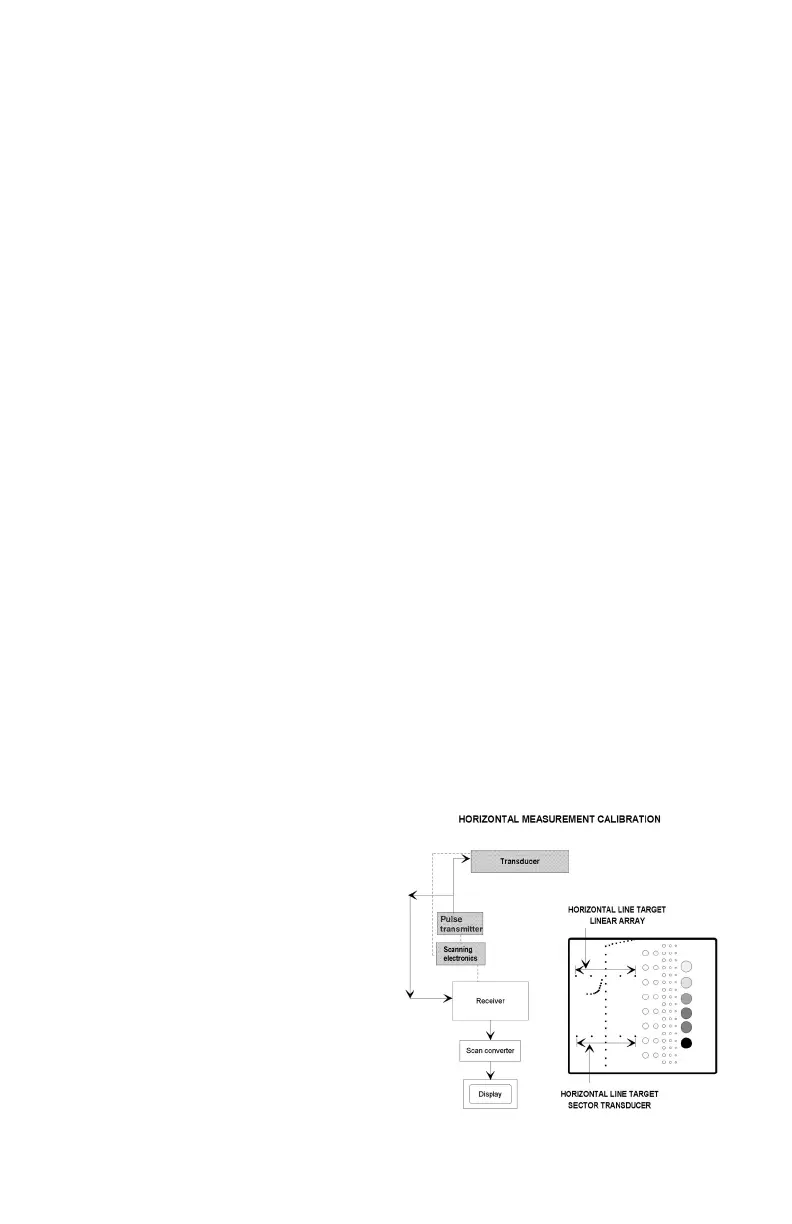

HORIZONTAL DISTANCE MEASUREMENTS

Horizontal distance measurements are obtained perpendicular to the axis of the

sound beam. Proper diagnosis is dependent upon the accurate representation of

the size and volume of a structure being examined. Most imaging systems use

distance markers and/or electronic calipers to obtain these measurements. The

phantom is scanned and a distance measurement obtained. The resulting mea-

surement is then compared to the known distance in the phantom. The accuracy

of the horizontal distance measurements is dependent upon the integrity of the

transducer, the output intensity and the resolution of the imaging system. Testing is

performed as follows:

Note: The Model ATS539 Multipurpose phantom provides two scanning surfaces

used to evaluate horizontal measurement calibration. Linear array scanning sys-

tems should use #1 scanning surfaces. Sector scanning systems should use #3

scanning surfaces.

1. Place the phantom on a clean, at surface

2. Apply an adequate amount of low viscosity gel or water to the scan surface. If

water is used, ll the scanning well slowly to avoid introduction of air bubbles.

3. Adjust the instrument settings (TGC, output, etc.) to establish baseline values

for "normal" scanning. If the bottom of the phantom is seen, adjust

the gain settings until the image goes entirely black. Record these settings

on the quality assurance record. These settings should be used for subsequent

testing.

4. Position the transducer over the horizontal group of line targets until a clear

image is obtained. Freeze the image.

5. Using the electronic calipers or the timing markers measure the greatest

distance that can be clearly imaged between line targets displayed.

Note: Some sector scanners have distance markers on the outside edges of the

sector image with no other indicators available. Hand-held calipers must be used

for distance measurements within the

image on the monitor.

6. Document all of the measurements

on the quality assurance record.

Results:

Interval Spacing: 2.0 cm ± 1 mm

Depths: 5.0 cm ±.1 mm (Scan surface

#1) 5.0 cm ±.1 mm (Scan surface #3)

Loading...

Loading...