6

3. Adjust the instrument settings (TGC, output, etc.) to establish baseline

values for "normal" scanning. If the bottom of the phantom is seen,

adjust the gain settings until image goes entirely black. Record these settings

on the quality assurance record. These settings should be used for subsequent

testing.

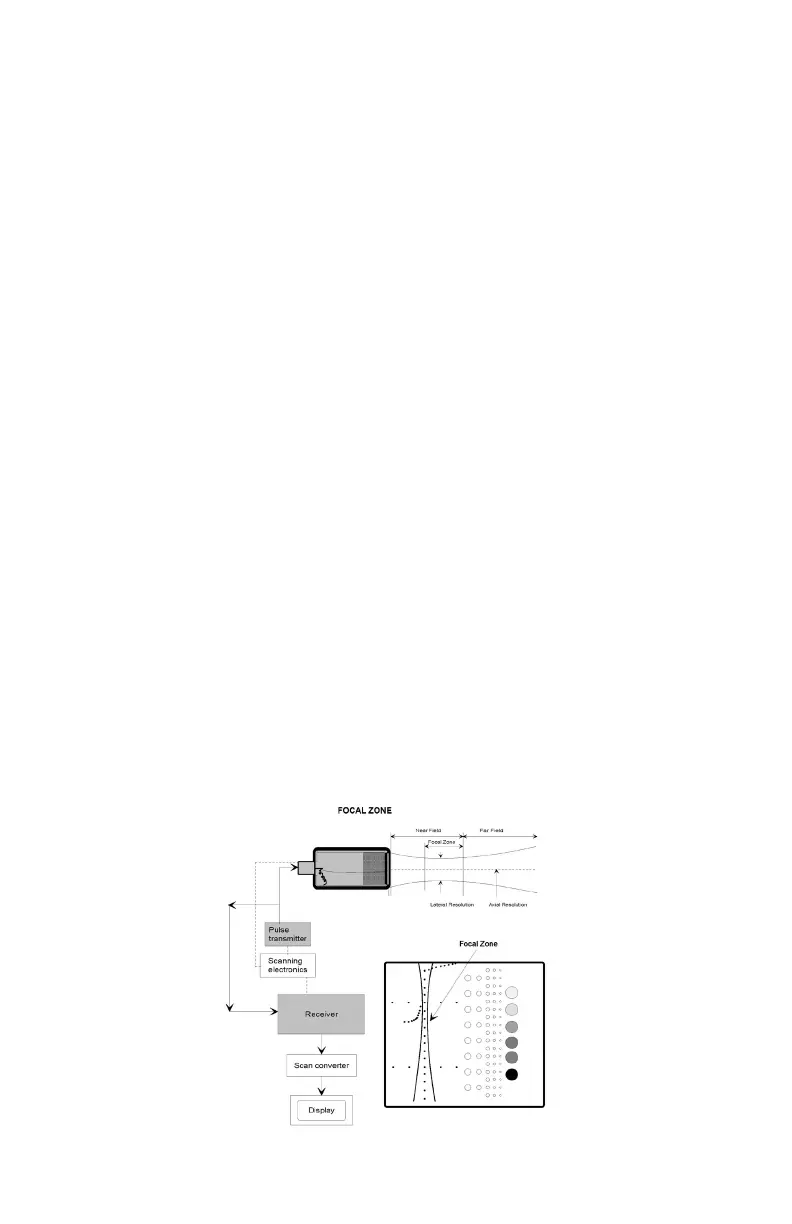

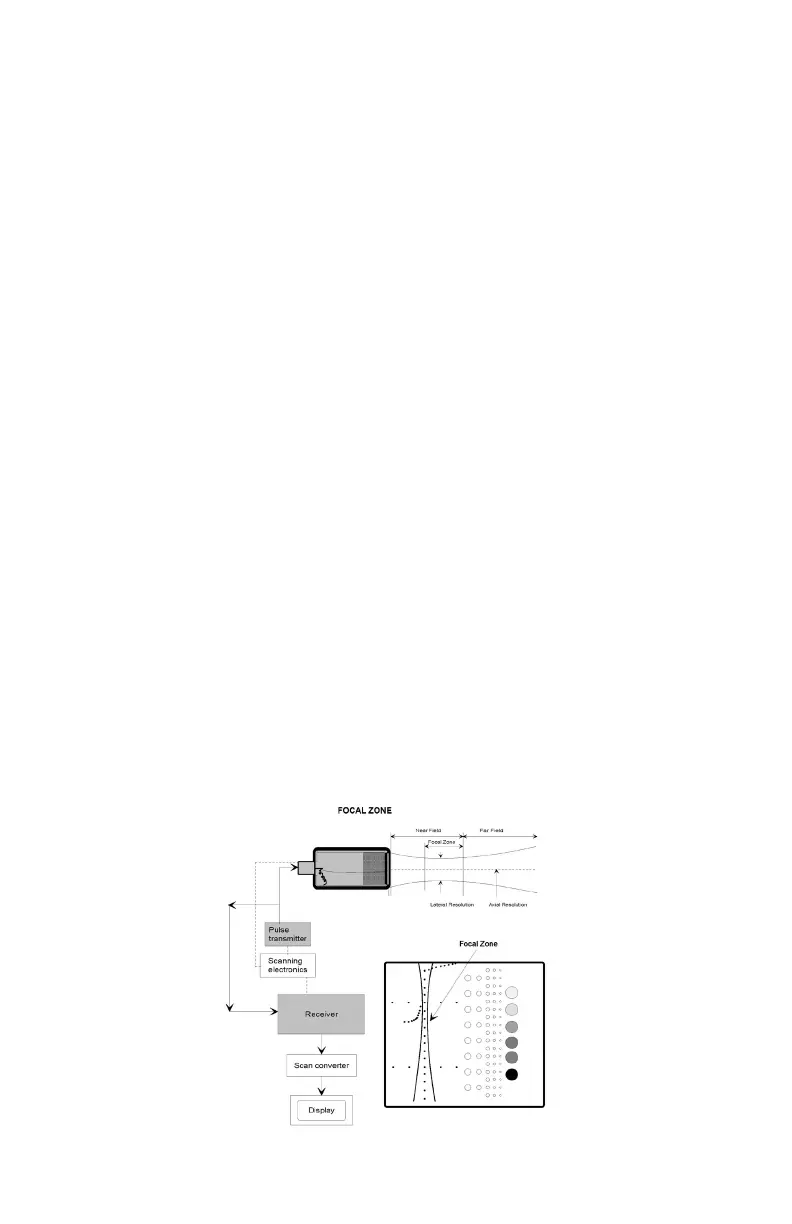

4. Position the transducer over the vertical group of line targets on the phantom,

until a clear image is obtained. Freeze the display and obtain a hard copy.

NOTE: A line rather than a dot is produced on the display. The length of the line is

indicative of the width of the beam. Therefore, targets inside the focal zone form a

shorter line than those outside of the focal zone. Adjustments in the gain settings

will change the length of the line targets displayed.

5. For a variable focused transducer, scans with several different focal zone

settings should be performed. Dynamically focused transducers may not

display changes in the width of the line targets. However a change in the

intensity can be observed upon adjustment of the transmitting focus of the

transducer.

6. Using the hard copy, draw a line connecting the ends of the echoes received

from the line targets (both sides), the line should form a smooth curve. This will

illustrate the shape of the sound beam. Now locate the narrowest portion,

this is the focal zone. Measure the width of the beam and the depth at this

point.

7. Document the depth of the focal zone and the measurement of the focal width

on the quality assurance record.

Results:

The location of the focal zone should agree with the manufacturer's specica-

tions and should not change with time. This applies to both xed and dynamically

focused systems. If changes occur corrective action should be considered.

Loading...

Loading...