Maintain sufficient distance between the communication cable and the power and motor cable.

Do not bundle communication and power cable as it may cause communication errors and failures due to

instability caused by noise.

Refer to materials such as DeviceNet laying manual for details on laying the cables.

Safety precautions

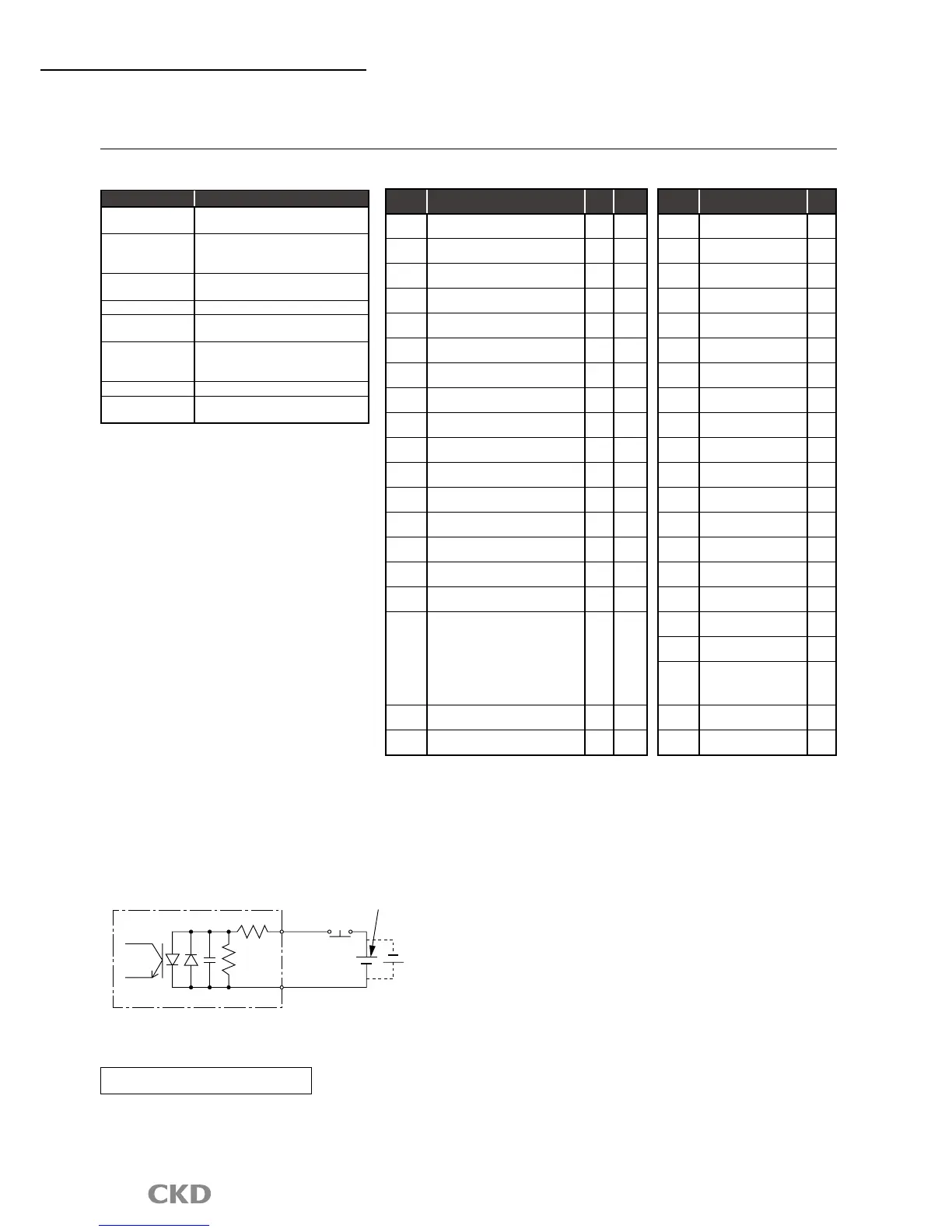

I/O signal

Byte

No.

Signal name

Logic

Judgment

0.0

Program no. selection input (bit 0)

Positive

Level

0.1

Program no. selection input (bit 1)

Positive

Level

0.2

Program no. selection input (bit 2)

Positive

Level

0.3

Program no. selection input (bit 3)

Positive

Level

0.4

Program no. selection input (bit 4)

/program no. setting input the second digit

Positive

Level

edge

0.5

Program no. setting input the first digit

/program no. selection input (bit 5)

Positive

Level

edge

0.6 Reset input

Positive

Edge

0.7 Return to origin command input

Positive

Edge

1.0 Start input

Positive

Edge

1.1

Servo on input

/program stop input

Positive

Level

edge

1.2

Ready return input

/continuous rotation stop input

Positive

Edge

1.3

Answer input

/position deviation count reset

Positive

Edge

1.4 Emergency stop input

Negative

Level

1.5 Brake release input

Positive

Level

1.6 Not available

1.7 Not available

2.0

to

2.5

Not available

2.6 Monitor output action request

Positive

Level

2.7 Command execution request

Positive

Edge

Communication specifications

Descriptions Specifications

Power supply for

communication

11 to 25 VDC

Current consumption

of power supply for

communication

50mA or less

Communication

protocol

DeviceNet compliant: remote I/O

Occupying nodes Input 8 byte/output 8 byte

Communication speed

500k/250k/125kbps

(Select with the parameter setting.)

Connection cable

DeviceNet compatible cable

(Shielded 5 wire cable,

2 signal lines, 2 power lines, 1 shield)

Node address 0 to 63 (set with parameter)

Connection

quantity

Max.64 unit (including master)

DeviceNet specifications (available soon)

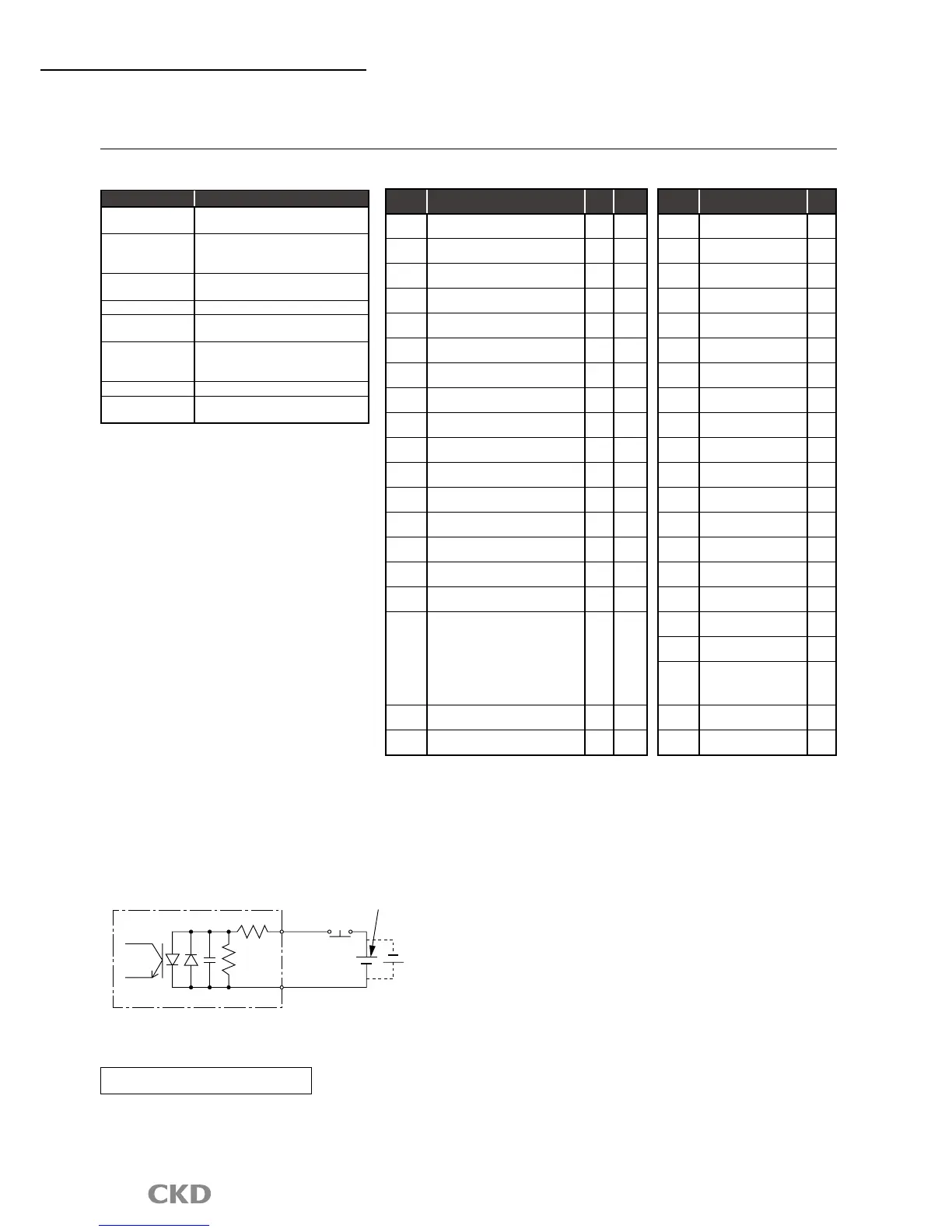

Byte

No.

Signal name

Logic

0.0 M code output (bit 0)

Positive

0.1 M code output (bit 1)

Positive

0.2 M code output (bit 2)

Positive

0.3 M code output (bit 3)

Positive

0.4 M code output (bit 4)

Positive

0.5 M code output (bit 5)

Positive

0.6 M code output (bit 6)

Positive

0.7 M code output (bit 7)

Positive

1.0 Inposition input

Positive

1.1

Positioning complete

output

Positive

1.2

Start input waiting

output

Positive

1.3 Alarm output 1

Negative

1.4 Alarm output 2

Negative

1.5

Output during indexing 1

/origin position output

Positive

1.6

Output during indexing 2

/servo state output

Positive

1.7 Ready output

Positive

2.0 Output

Positive

2.1 M code strobe output

Positive

2.2

to

2.5

Not available

2.6 Monitor medium

Positive

2.7

Command completion

Positive

PLC

→

AX(Input)

AX

→

PLC(Output)

Loading...

Loading...