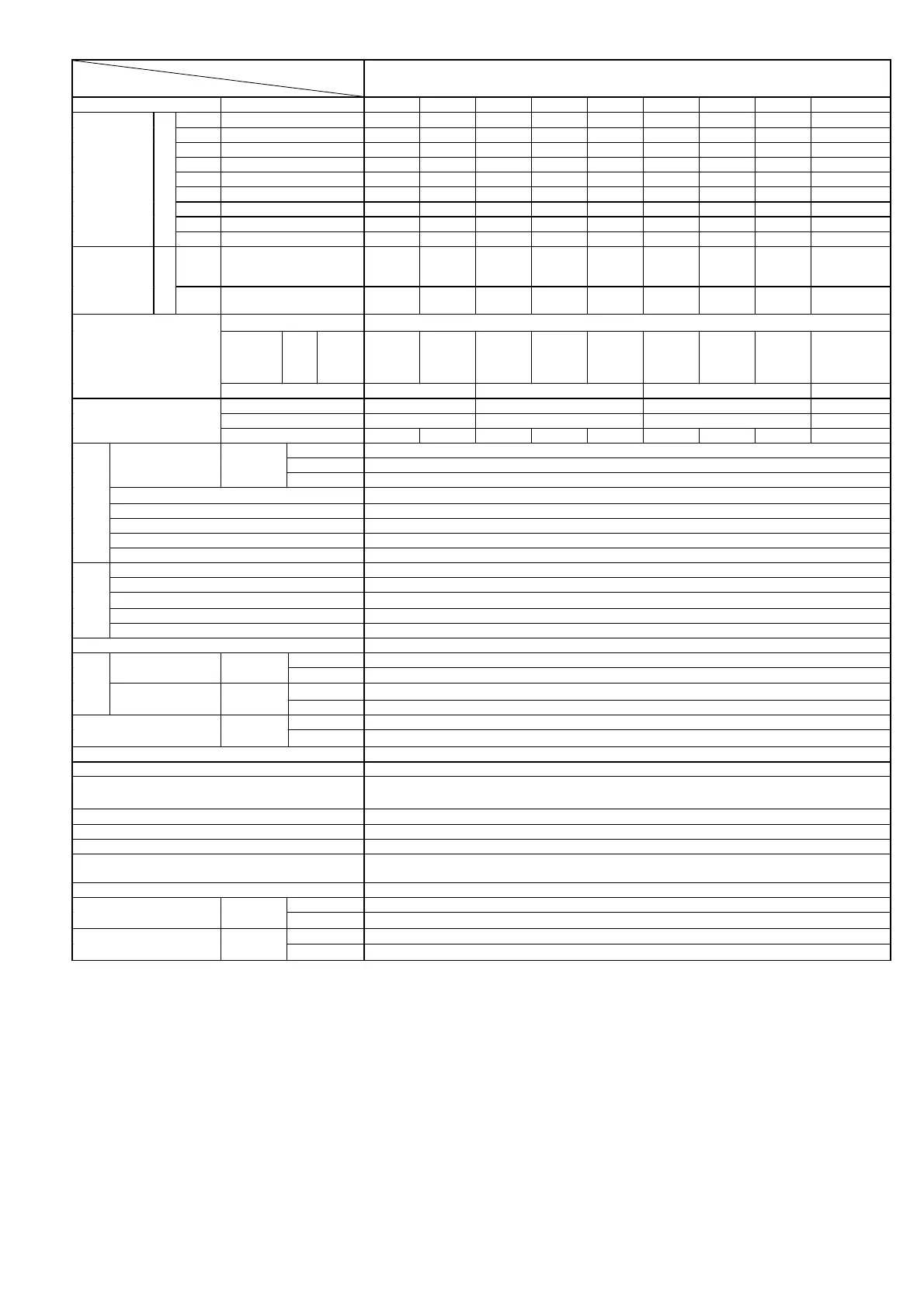

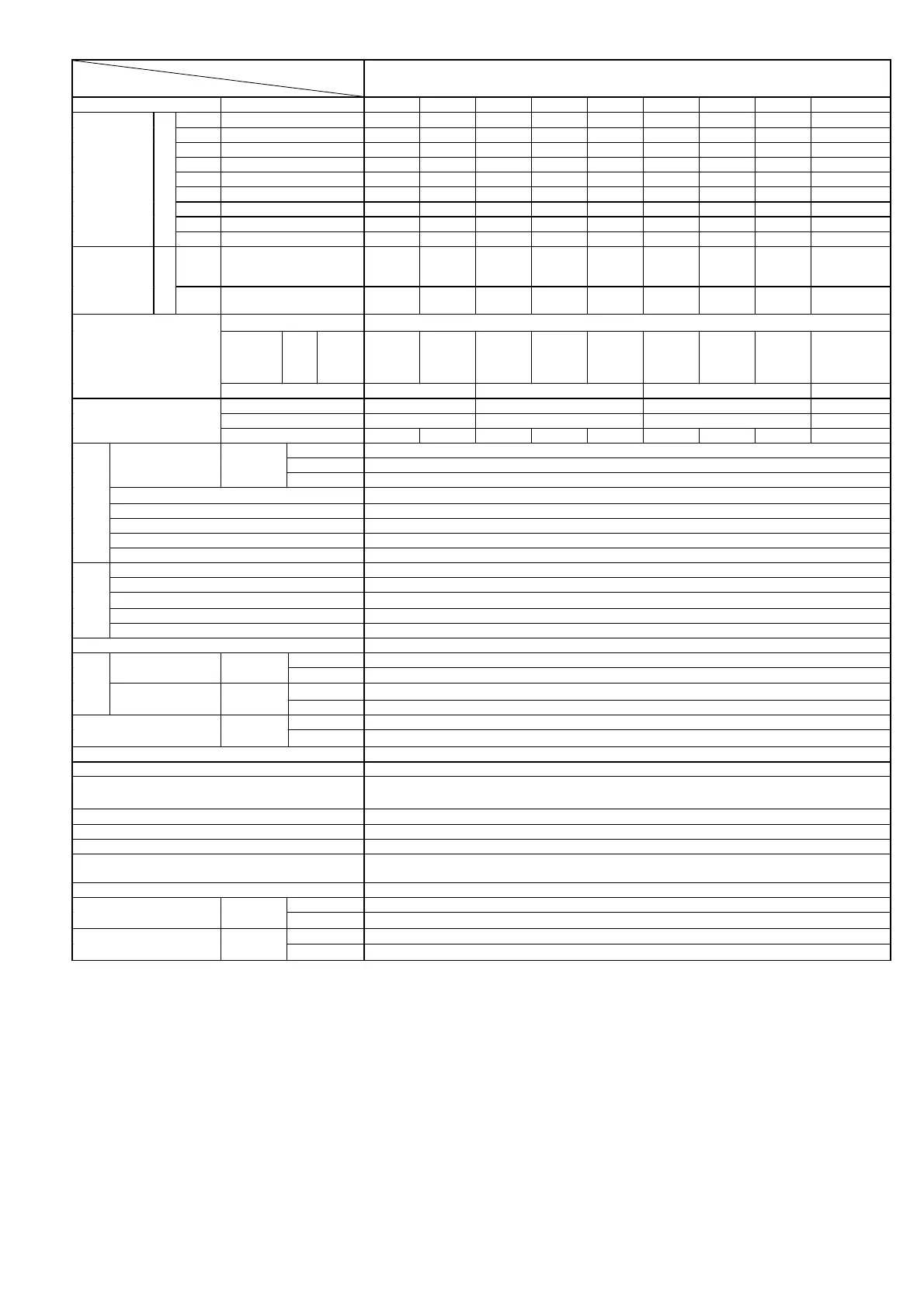

Integrated indicator type (Stainless body)

Model no.

Descriptions

Integrated indicator type (Stainless body)

FSM2-[*1][*2][*3][*4]-[*5][*6]

Full scale flow rate 005 010 020 050 100 200 500 101 201

005 500mL/min

●

010 1L/min

●

020 2L/min

●

050 5L/min

●

100 10L/min

●

200 20 L/min

●

500 50 L/min

●

101 100 L/min

●

Full scale

flow rate

Note 1

*4

201 200 L/min

●

S06 Rc1/8 / Stainless

● ● ● ● ● ●

●

(only Air,

Ar)

Poet size/

Body

material

*5

S08 Rc1/4 / Stainless

● ●

●

(only Air, Ar)

Type of display Dual (2×4-digit 7-segment) Two-color LCD

Flow

rate

range

*3 F

0 to

500

mL/min

0 to

1000

mL/min

0 to

2.00

L/min

0 to

5.00

L/min

0 to

10.00

L/min

0 to

20.0

L/min

0 to

50.0

L/min

0 to

100.0

L/min

0 to

200

L/min

Flow rate display

Note 1、2

Display resolution 1mL/min 0.01L/min 0.1L/min 1L/min

Flow rate range 9999999mL 99999.99L 999999.9L 9999999L

Display resolution 1mL 0.01L 0.1L 1L

Integrating function

Note 3、7

Integrating pulse output rate

5mL

10mL 0.02L 5mL 10mL 0.02L 5mL 10mL 2L

Blank Clean air (JIS B 8392-1.1.1 to 5.6.2), Compressed air (JIS B 8392-1.1.1~ 1.6.2), and Nitrogen gas

AR Argon

Working fluid

Note 4

*6

C2 Carbon dioxide

Maximum working pressure 1.0MPa

Minimum working pressure -0.09MPa

Withstanding pressure 1.5MPa

Ambient temperature / humidity 0 to 50°C and 90%RH or less

Working

conditions

Working fluid temperature 0 to 50°C (to be no dew condensation.)

Flow rate range 3 to 100%F.S.

Linearity (display / analog output) ±3%F.S. or less (25°C, 1 atmospheric pressure)

Pressure characteristics ±5%F.S. or less (-0.09 to 0.7MPa, 25°C, 1 atmospheric pressure criteria)

Temperature characteristics ±0.2%F.S./°C or less (15 to 35°C, 25°C criteria)

Accuracy

Repeatability ±1%F.S. or less

Response time Note3 50ms or less

N 2 points (NPN open collector output, 50mA or less, voltage drop 2.4V or less)

Switch output *1

P 2 points (PNP open collector output, 50mA or less, voltage drop 2.4V or less)

V 1 point (1 to 5V voltage output and connected load impedance 50kΩ and over)

Output

Analog output *2

A 1 point (4 to 20mA current output and connected load impedance 300Ω or less)

V DC12 to 24V (10.8 to 26.4V)

Power supply voltage *2

A DC24V (21.6 to 26.4V)

Current consumption Note8 50mA or less

Lead wire φ3.7 AWG26×5

Functions

Flow rate display, flow rate display-peak hold, switch output and analog output,

Outside diam eter of insulator is Φ 1.0

Installation attitude Both vertical and horizontal

Strait piping section Not required

Protective structure Note 9 IEC standards IP40

Protective circuit Note5

Power supply and switch output reverse connection protections, and switch output

load short-circuit protection

EMC instruction Acceptable goods

S06 Approx. 160g Mass

(Only the main body)

*5

S08 Approx. 200g

P70 Particle occurrence prevention Note10

Clean specification *7

P80 Oil treatment prohibited

Note11

-9-

Note1: Converted to volumetric flow at 20°C and 1 atmospheric pressure (101kPa)

Note2: Flow late display is only the read within rough±1%F.S.

Note3: Integranted flow display is reference value.

Note4: When using compressed air, use clean air complying with JIS B 8392-1:2003 class over 1.1.1 to 1.6.2. Compressed air from the compressor contains drainage (water, oxidized oil,

foreign matter, etc.). Install a filter(filtration rating:5µm), air dryer(minimum pressure dew point 10℃ or less) and oil mist filter(maximum oil concentration 0.1mg/m

3

) on the primary

side of the product to maintain product function.

When using for purposes other than compressed air, use dry gas that does not contain corrosive elements such as chlorine, sulfur or acids, and clean gas that does not contain dust

or oil mist.

Note5: The response time can be selected from 50ms to 1500ms.

Note6: Current consumption is different according to the state of the load.

Note7: Integrated flow value is reset by turning power off.

Note8: Current consumption is characteristics 24VDC and no load. It is changed by load. Please note it.

Note9: This product’s protective circuit is effective only for specific incorrect connections and load short-circuits. It does not necessarily provide protection for all incorrect connections.

Note10:<P70>Particle occurrence prevention (It is washing of remove fat to surface of product before it wraps it. And heat seal wrapping to antistatic bag inside clean work

station.(Class:100 or more ))

Note11:<P80>Oil treatment prohibited (In addition to the P70 specification, It is washing of removing fat to touching gas. Please refer, Touching gas material is internal structural chart.)

Loading...

Loading...