WS1 & 1.25 Man u al Page 5

Table 4 shows the order of the cycles when the valve is set up as a lter. When the control valve is used as a down ow

re gen er at ing lter, the OEM has the option to specify one backwash or two backwashes. If the control valve is set to

regenerate for a lter, the OEM has the option of having the regenerant re ll after the rinse cycle or have the regenerant pre ll

before regeneration. If the OEM chooses to have the regenerant pre ll before regeneration, the pre ll starts two hours before

the regeneration time set. During the 2-hour period in which the regenerant is being made, treated water is still available. For

example: regeneration time = 2:00 am, pre ll option selected, down ow lter. Fill occurs at 12:00 a.m., start of backwash

cycle occurs at 2:00 a.m. There is only one rinse. Backwashes can be set to normal or longer. The option selected will apply to

all backwashes. Tables 5 and 6 show the length of the cycles when the valve is set up as a lter.

2

These are reference numbers that approximate the amount of salt needed. The actual capacity in grains per pound of salt is

used in cal cu la tions.

3

Total time does not include ll time, which is dependent upon the amount of salt needed. When in the ll mode the system

is providing treated water.

When the control valve is used as a non-regenerating lter, the OEM has the option to specify one backwash or two

backwashes. If two backwashes are speci ed, two rinses occur. Tables 5 and 6 show the length of the cycles when the valve

is set up as a lter. When used as a non-regenerating lter, the down ow piston must be installed, the regenerant piston

removed, injector plugs must be installed in both the DN and UP injector locations and the re ll elbow must be replaced with

a re ll port plug.

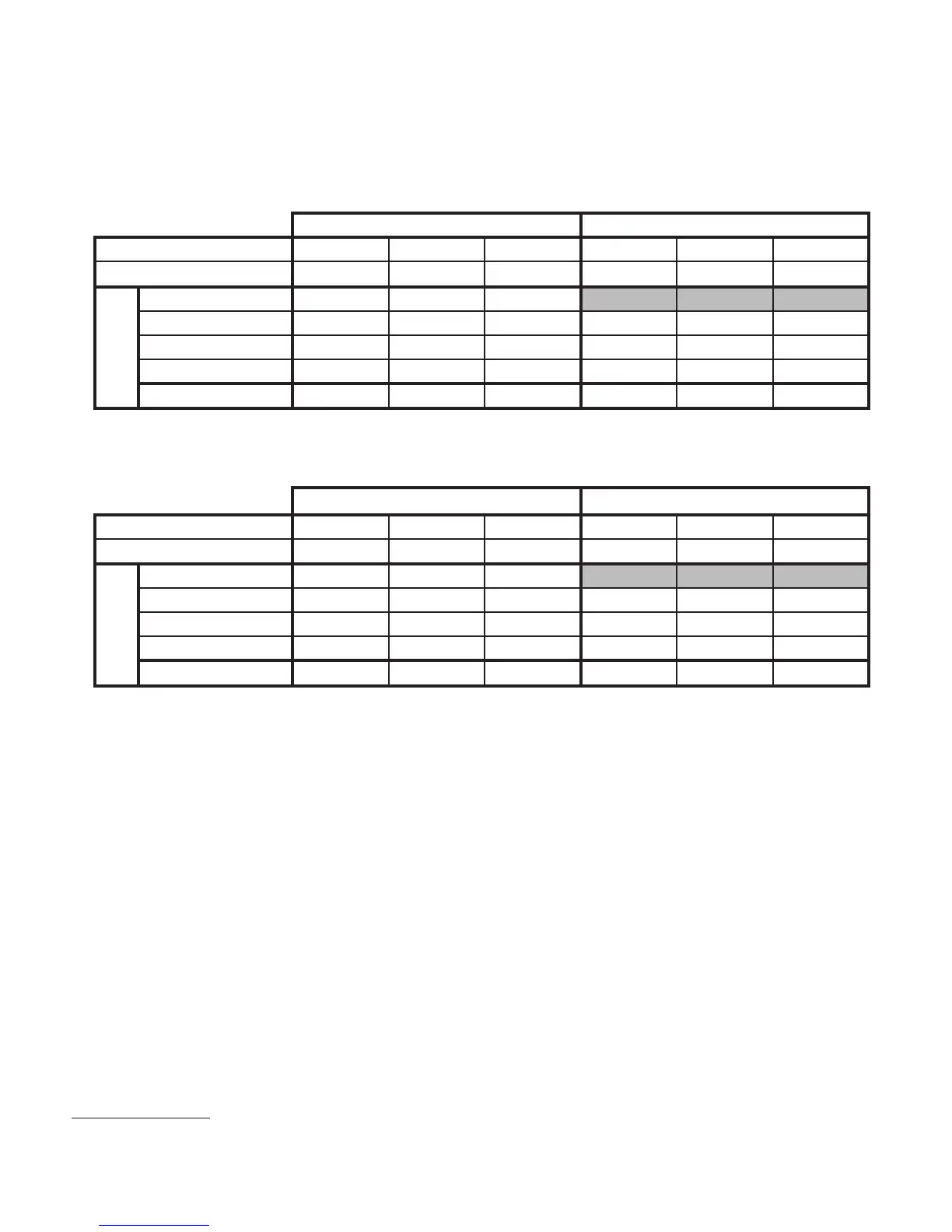

Table 2

Backwash Normal Length Softener

Cycle Times in Minutes

WS1 & WS1.25 Downfl ow Softener WS1 & WS1.25 Upfl ow Softener

Grains Capacity/lb NaCl 6000 to 3501 3500 to 2501 2500 to 1700 6000 to 3501 3500 to 2501 2500 to 1700

lbs NaCl/cu ft resin

2

Less than 7.5 7.5 to 12 More than 12 Less than 7.5 7.5 to 12 More than 12

Backwash Normal 6 8 8

Regenerate 45 60 75 45 60 75

Backwash Normal 3 8 10 6 10 12

Rinse 346346

Total

3

57 80 99 54 74 93

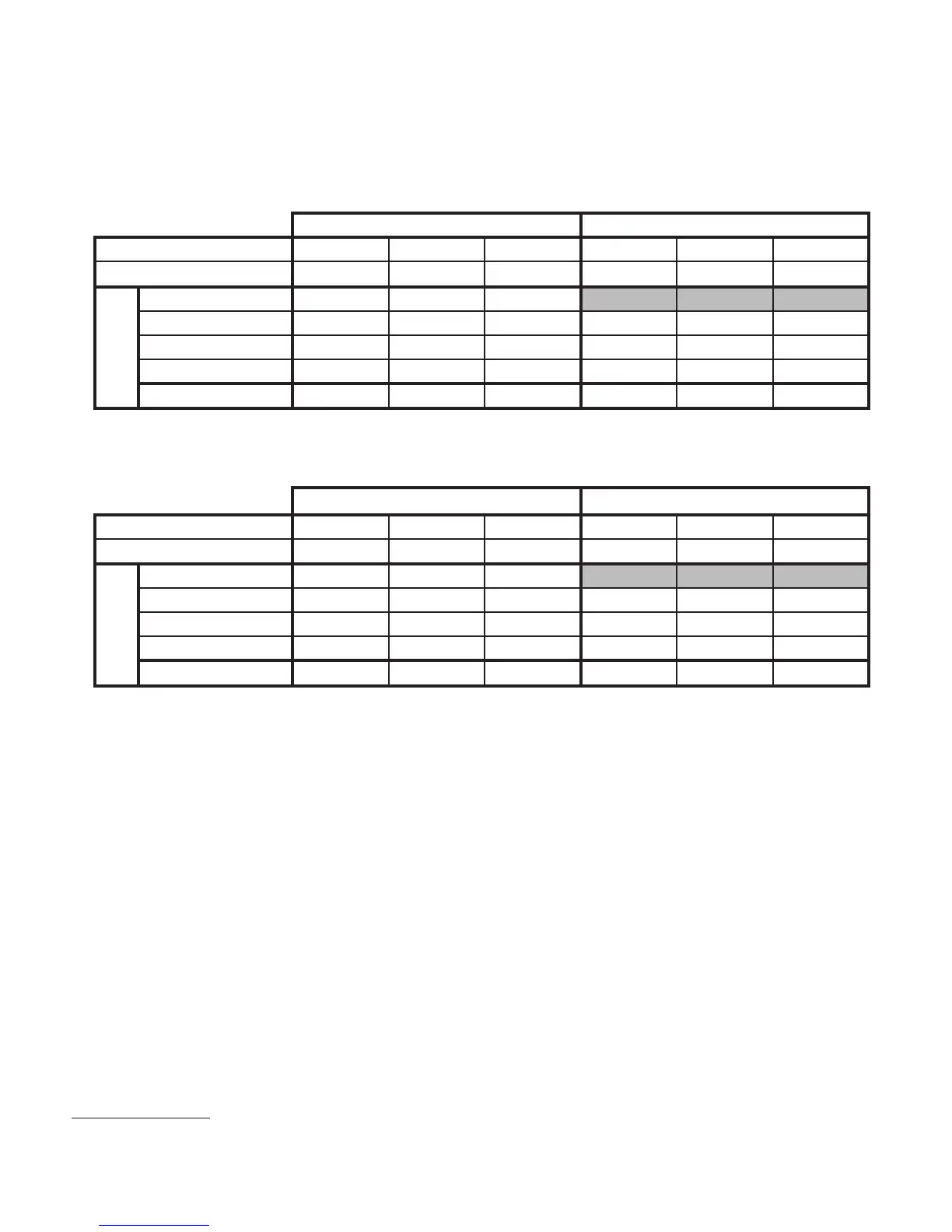

Cycle time

in Minutes

WS1 & WS1.25 Downfl ow Softener WS1 & WS1.25 Upfl ow Softener

Grains Capacity/lb NaCl 6000 to 3501 3500 to 2501 2500 to 1700 6000 to 3501 3500 to 2501 2500 to 1700

lbs NaCl/cu ft resin

2

Less than 7.5 7.5 to 12 More than 12 Less than 7.5 7.5 to 12 More than 12

Backwash Longer 8 10 12

Regenerate 45 60 75 60 70 80

Backwash Longer 8 10 12 12 14 16

Rinse 468579

Total

3

65 86 107 77 91 105

Cycle time

in Minutes

Table 3

Backwash Longer Length Softener

Cycle Times in Minutes

When set up as a softener the backwash and rinse cycles automatically increase with increasing salt dosage. Backwashes can

be set to be NORMAL or LONGER. The option selected will apply to all backwashes. Tables 2 and 3 show the length of the

cycles when the valve is set up as a softener.

Loading...

Loading...