EN

ENGLISH

Clarke

®

American Sanders Operator's Manual (EN) - OBS-18/18DC HDTR FORM NO. 70403B - 9 -

Sanding Cuts and Sandpaper

Initial Cut

The purpose of the initial cut is to remove old fi nish and gross imperfections on the fl oor surface. Use a course (20-36 grit) grain

abrasive.

Final Cuts

The purpose of a fi nishing cut is to remove the scratches produced during the initial cut. Use a fi ne (60-80 grit) grain abrasive.

If the surface remains rough after a fi nishing cut, it may be necessary to use an even fi ner grain of abrasive (80-100grit). Care should

be taken in selecting the grit size of the abrasive. A very fi ne grain will close the pores on a wood fl oor making admission of a stain

diffi cult.

If glazing or burning should occur the abrasive has dulled and must be replaced.

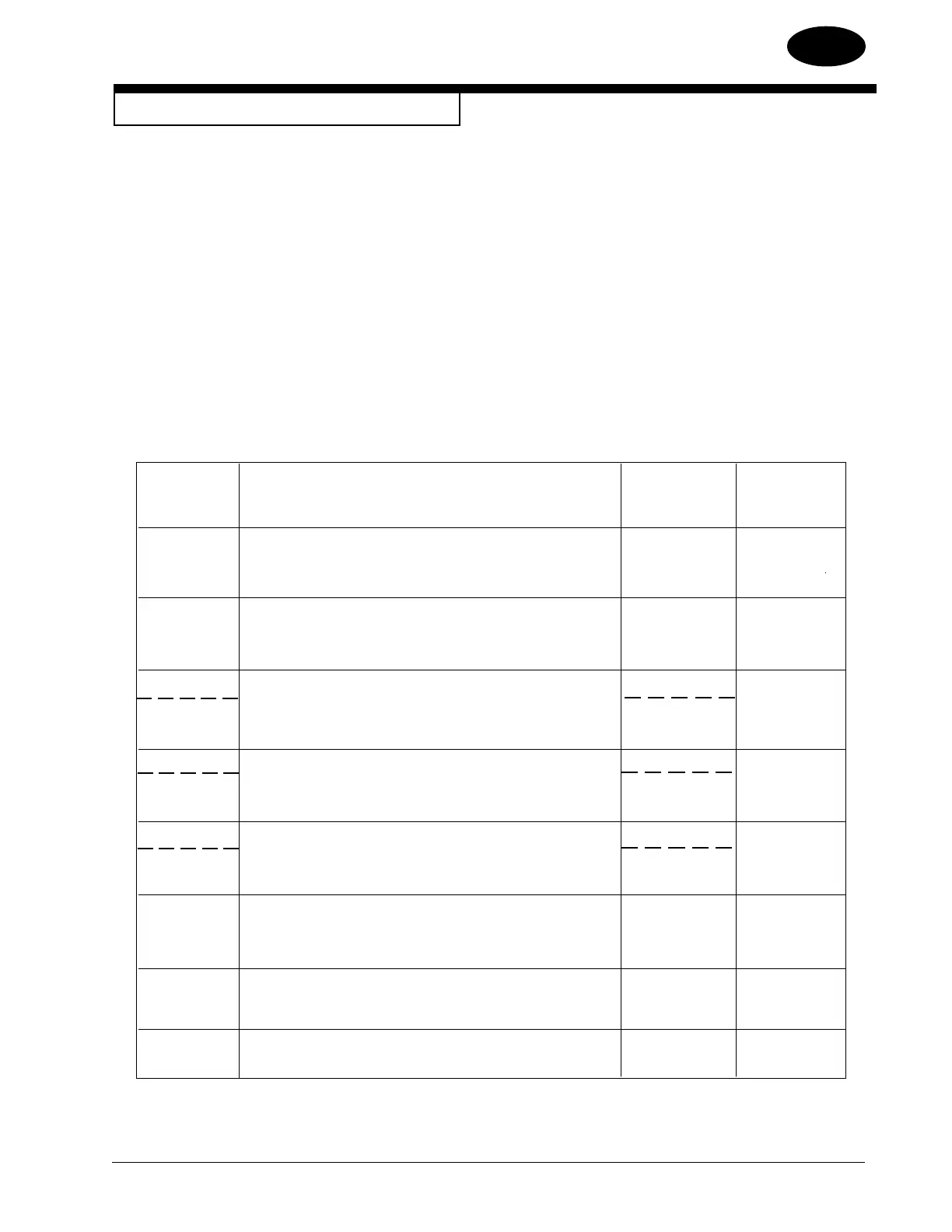

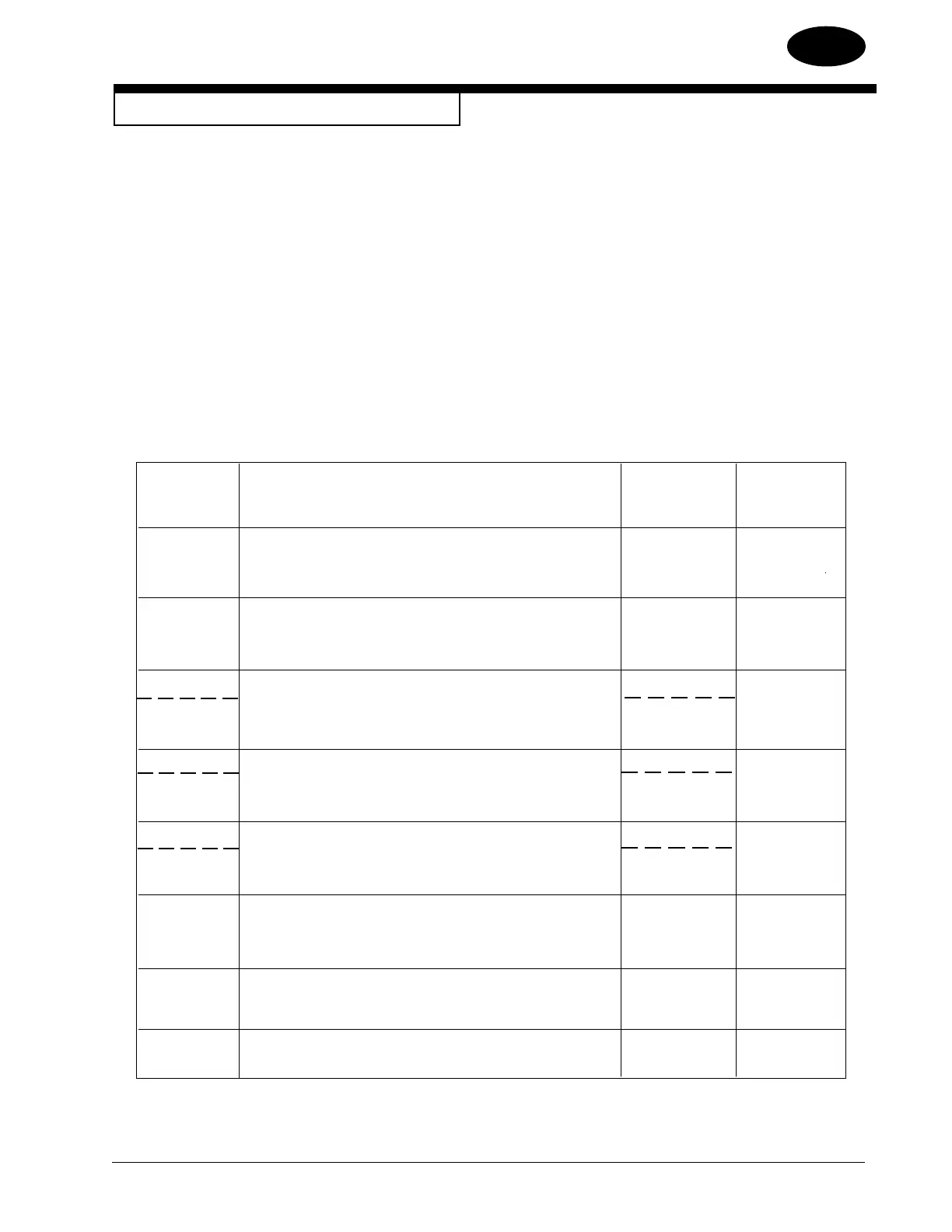

Standard Professional

Grain Use Grade Grade

Part # / Qty Part # / Qty

20 grit For removing gross imperfections and restoring

evenness to old fl ooring. To remove build-up of 945950 / 10

paints and varnishes.

36 grit For fi rst sanding of new fl ooring (maple, oak).

For removing minor imperfections and fi nishes 945951 / 20

from old fl ooring.

60 grit For cleanup from initial cut 36 grit. 945954 / 20

60 grit 945960 / 20

screen mesh

80 grit For fi nal sanding of certain hardwoods. For 945955 / 20

80 grit cleanup of initial cuts (60 grit). 945961 / 20

screen mesh

100 grit For fi nal sanding of certain hardwoods and 945956 / 20

100 grit conifers where a smooth surface is desired. 945962 / 20

screen mesh

120 grit For fi nal sanding of certain hardwoods and

screen mesh conifers where a smooth surface is desired. 945963 / 20

For leveling after initial fi nish coat.

150 grit For scratching surface between coats of fi nish. 945964 / 20

screen mesh

180 grit For surface roughing between coats of fi nish.

screen mesh

Loading...

Loading...