DAILY MAINTENANCE:

Follow same procedure for Shut Down and Storage:

PERIODIC MAINTENANCE:

1. Twice a month, flush a white vineger solution

(one quart vinegar to two gallons water) or anit-

browning solution (mixed as directed) through the

extractor. This will prevent build-up of alkaline

residue in the system.

2. If spray jet becomes clogged, remove the spray

tip, wash it thoroughly, and blow dry. NOTE: DO

NOT USE PINS, WIRE, ETC. TO CLEAN

NOZZLE AS THIS COULD DESTROY THE

SPRAY PATTERN.

3. Apply silicone lubricant to solution nipple.

4. Periodically inspect all hoses, electrical cable

and connections on your machine Frayed or

cracked hoses should be repaired or replaced to

eliminate vacuum or solution pressure loss. If

the cable insulation on the power cord is broken

or frayed, repair or replace immediately. Don't

take chances with electrical fire or shock.

Only qualified maintenance personnel are to

perform the following repairs.

SOLUTION PUMP REPLACEMENT:

1. Turn off all switches and unplug the machine.

2. Unfasten screws holding pump plate to bottom of

solution tank.

3. Remove solution hoses from fittings on pump.

4. Remove pump from brackets and remove fittings

and grounding wire.

5. Reverse process to install new replacement

pump.

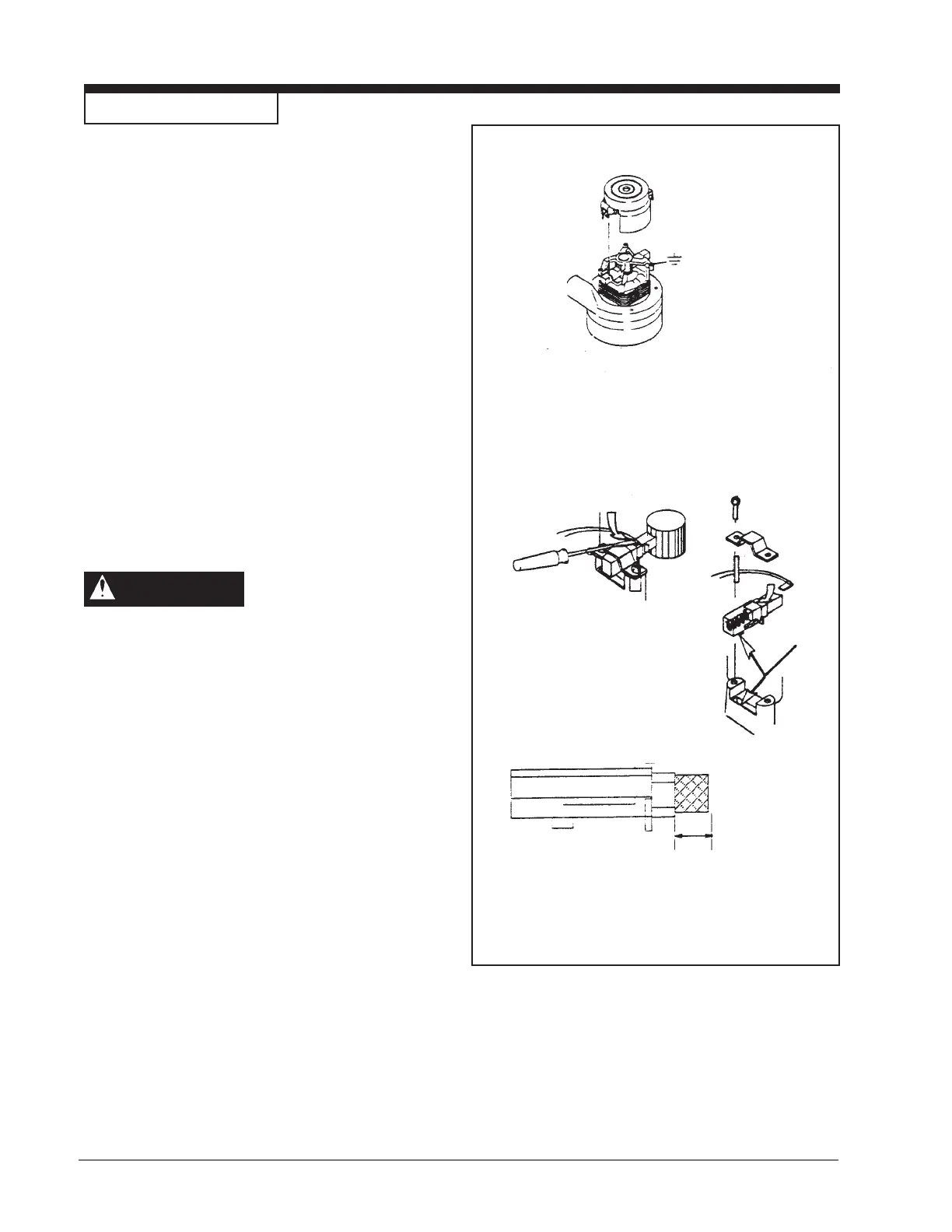

VACUUM MOTOR REPLACEMENT:

1. Turn off all switches and unplug machine.

2. Unfasten latch at back end of machine and

remove recovery tank.

3. Unfasten screws holding switch plate to solution

tank. Remove from solution tank. Locate the

vacuum motor wires and disconnect at the

connector.

4. Unfasten screws holding vac plate to switch

plate. Remove the vacuum motor.

5. Reverse process to install vacuum motor

replacement.

WARNING:

Page 4-1

Clarke

®

Operator's Manual -Image Mini Spot

Vac Motor Carbon Brushes

Replacement

Carbon

Brushes 115V

WARNING: The

green ground wire

must be attached for

safe operation. See

wiring diagram.

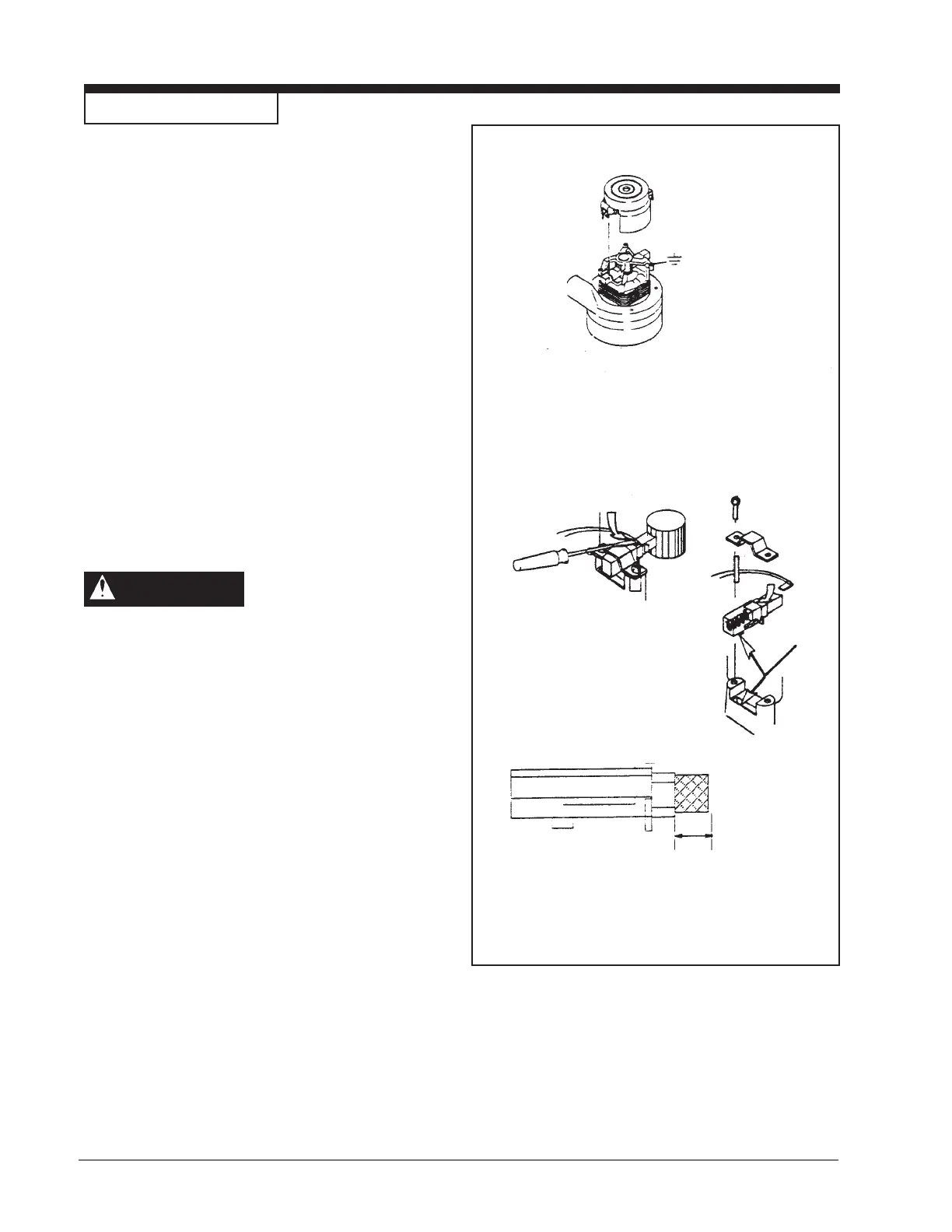

NOTE: When replacing carbon vac motor

brushes, loosen wire terminal BEFORE

removing screws on bracket.

If armature commutator is not concentric,

extremely pitted, or grooved, the motor will

need to be replaced or sent to a qualified

service center to restore vac performance.

Important:

These brushes wear

quicker as the length

shortens due to

increased heat.

Spring inside brush

housing will damage

motor if brushes are

allowed to wear away.

Periodically check the length of the carbon

brushes. Replace both carbon brushes when

either is less than 3/8" long.

MAINTENANCE

Loading...

Loading...