7

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

IMPORTANT: An air leak in the suction line will prevent priming, and reduce

the performance of the pump.

3. Pay particular attention to the following:

• Always ensure the hose adaptor sealing ring is in place and correctly

fitted.

• Always use a flexible hose at the pump body connection of at least

1ft (300 mm) length.

• Keep all pipes/hoses as short and straight as possible and avoid

sharp bends. If a flexible hose must be laid across a roadway,

protect it with planking.

• Ensure there is adequate drainage for the discharged water, and

that there is no danger of damage to property as a result of the

pumping activity.

NOTE: Instantaneous shut off pressure, applied when a vehicle runs

across an unprotected hose, will cause “hydraulic shock”, which

can damage the pump and/or the hose.

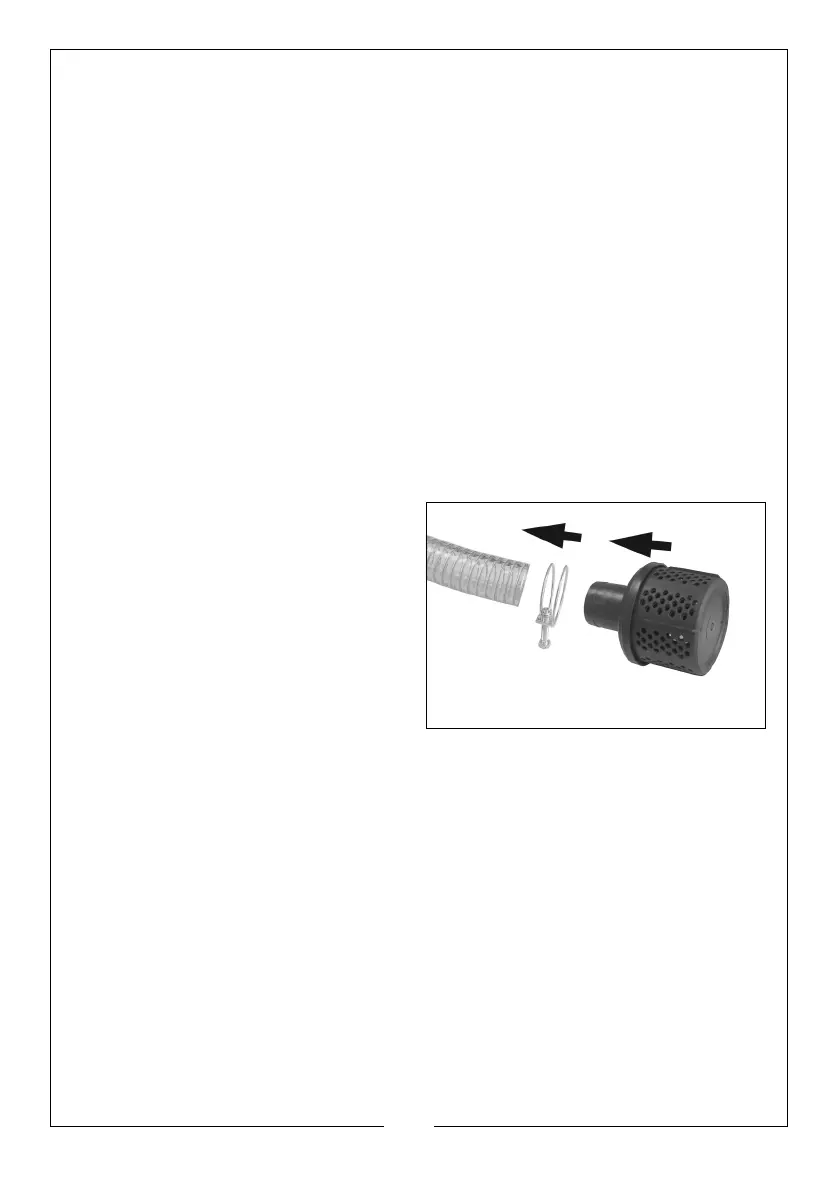

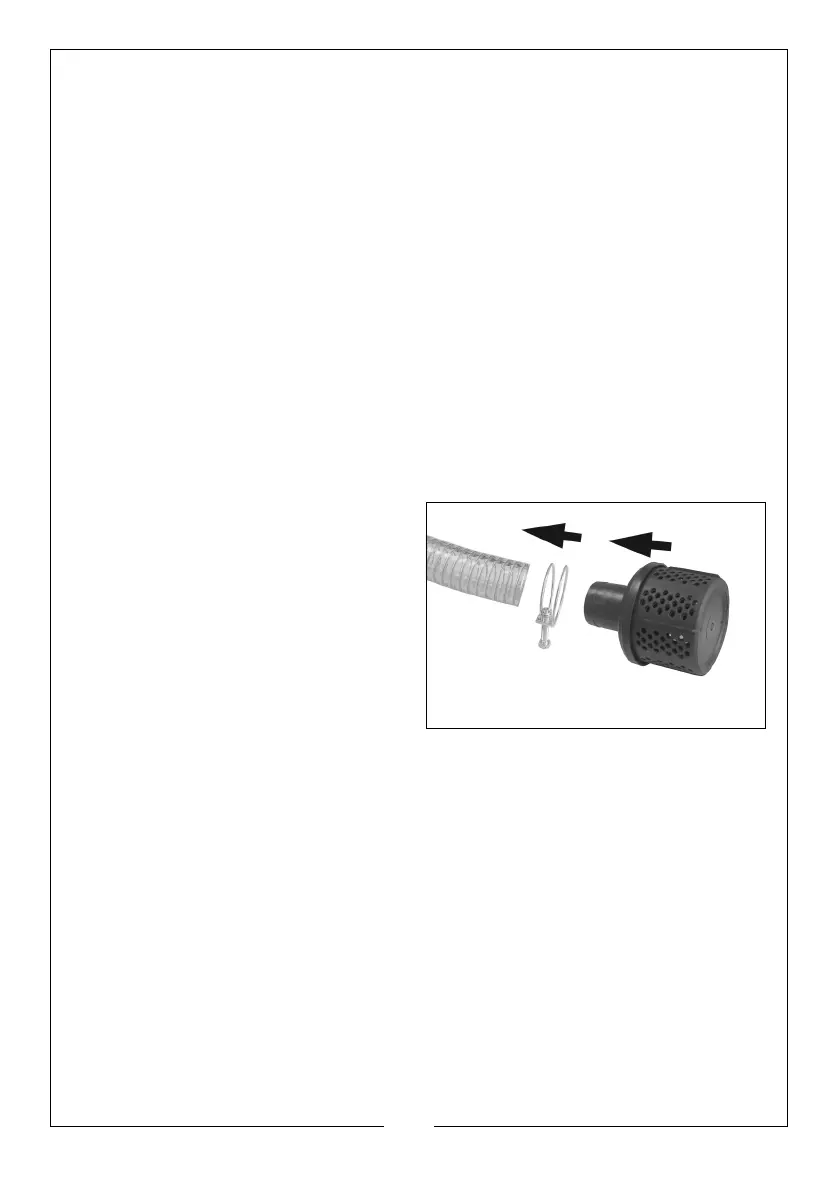

4. Attach the inlet strainer to the end

of suction hose using a further

hose clamp, to prevent large

stones etc, from being drawn up

which could cause severe

damage. Keep the strainer free of

debris.

5. If it is likely to clog with dirt or

debris, proceed by either:

• preparing a bed of stones on

which to rest the strainer.

• tying the strainer so that it stays off the bottom of the pit, pond or

excavation.

• rest the strainer inside a basket or bucket to keep undue debris

away.

Loading...

Loading...