Page 10 of 41

injured person permission from that person must be

received until you can help him. Unless the injury is

life threatening, move the injured person with

extreme care and then only if strictly necessary.

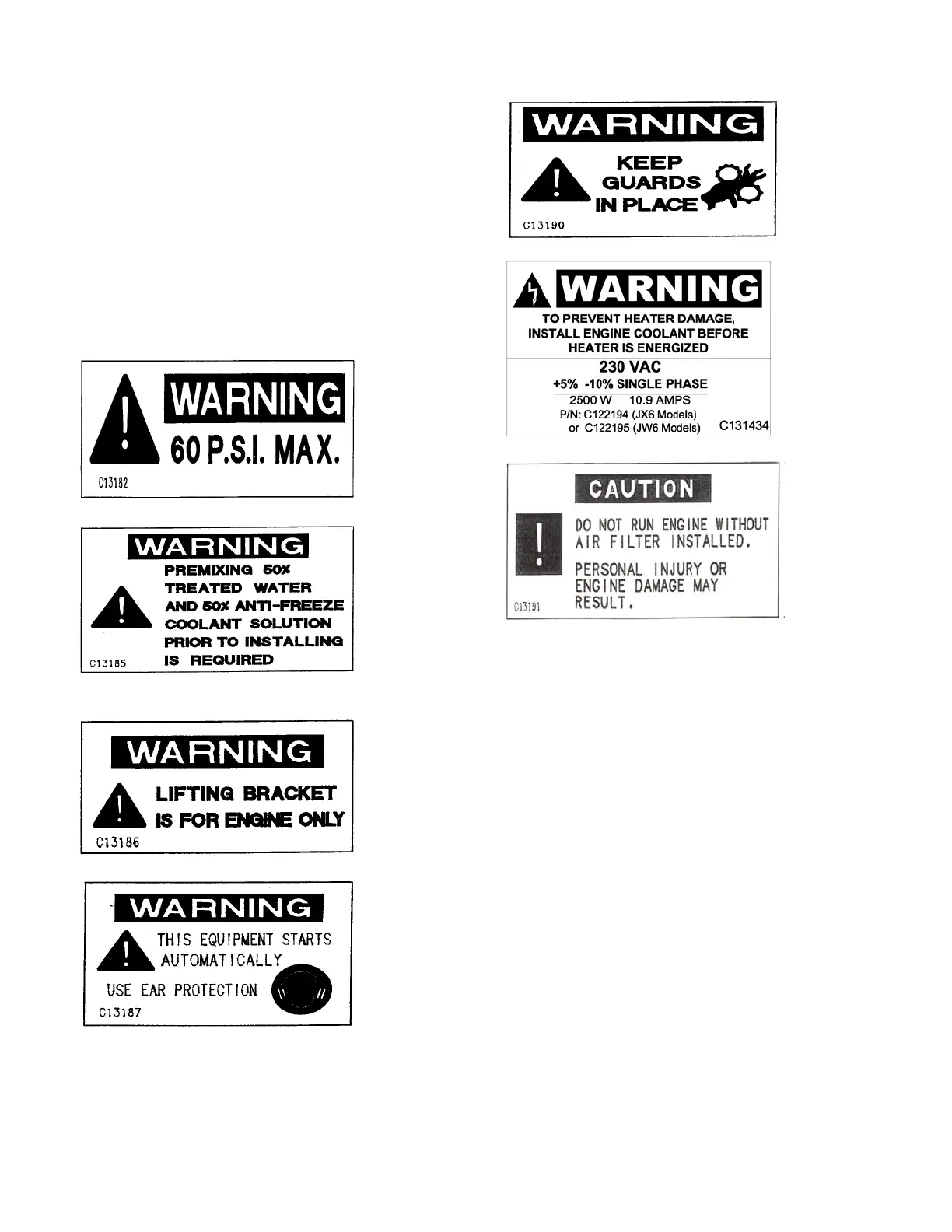

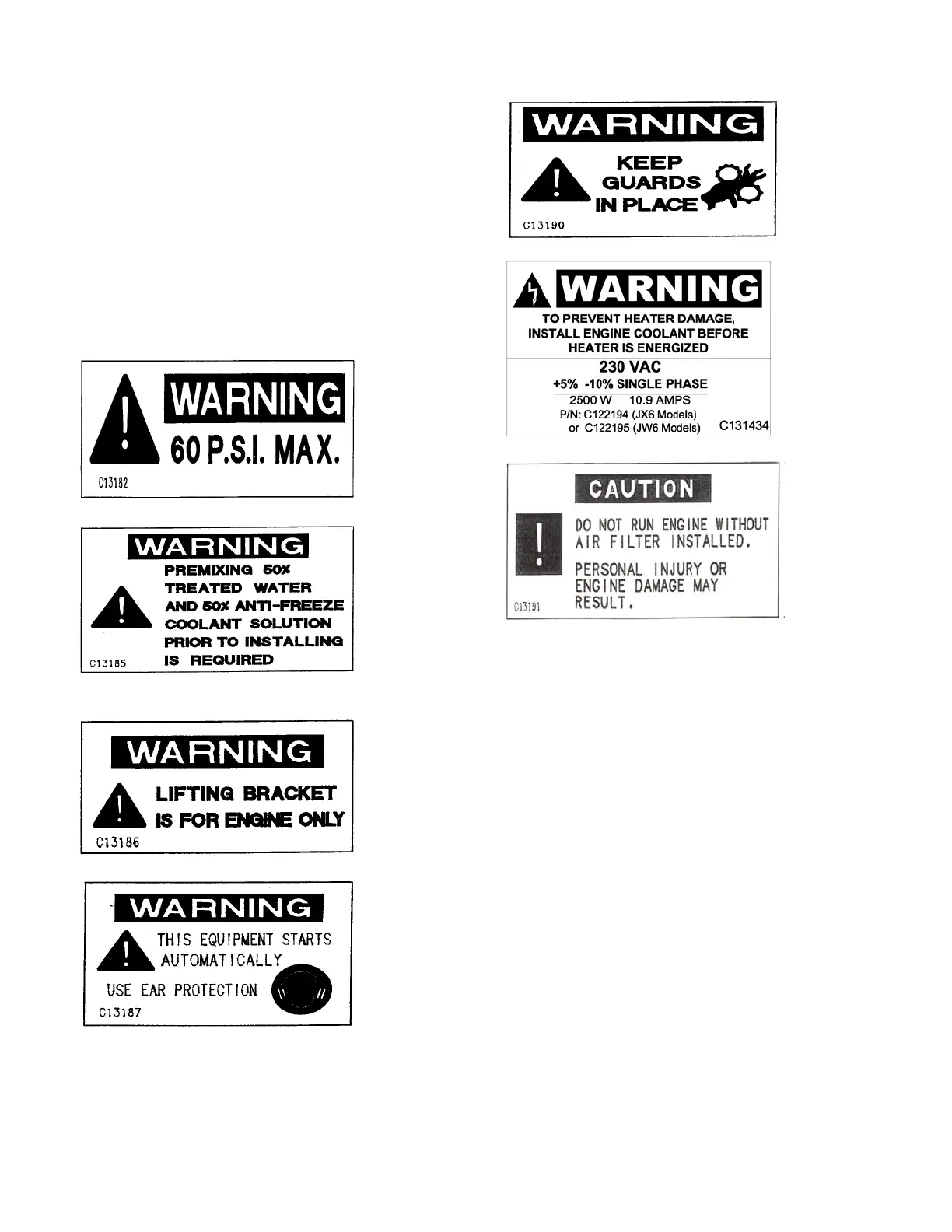

WARNING LABELS

Warning labels, in picture form, are applied to the

engine. Their meanings are given below.

Important Note: Labels that show an exclamation

mark indicate that there is a possibility of danger.

Heat Exchanger Maximum Working Pressure

Coolant Mixture

Lifting Point

Automatic Start

Rotating Parts

Jacket Water Heater Voltage

Air Filter Installation

2.0 INSTALLATION/OPERATION

2.1 TYPICAL INSTALLATION

A typical Fire Pump installation is shown in Figures

#6 & 6A.

1. Pump/Engine set

2. Main Pump Controller

3. Pump discharge

4. Air louver

5. Entrance door with air louver

6. Exhaust silencer

7. Exhaust system supports

8. Exhaust outlet pipe

9. Concrete base

10. Exhaust flexible connection joint/pipe

11. Air Discharge Duct from Radiator

NOTE: For radiator cooled engines, the total air

supply path to the pump room, which includes any

louvers or dampers, shall not restrict the flow of the

air more than 0.2” (5.1mm) water column. Likewise,

the air discharge path, which includes any louvers,

dampers, or ducting, shall not restrict the flow of air

more than 0.3” (7.6mm) water column.

Loading...

Loading...