Page 23 of 41

The installation of the exhaust system should consist

of the following:

Personnel protection from hot surfaces.

Adequate supports to prevent strain on the

engine exhaust outlet and minimize

vibration.

Protection against entry of water and other

foreign matter.

While the engine is running inspect exhaust pipe

outlet outside of the pump room itself for

environmental hazards such as excessive smoke

conditions. The following could be used as a guide

for general engine operating conditions.

1) Blue Smoke – Possible engine oil

consumption.

2) White Smoke – Possibility of water in

cylinders, water in fuel or internal engine

problem.

3.3 LUBRICATION SYSTEM

3.3.1 Checking Sump Oil

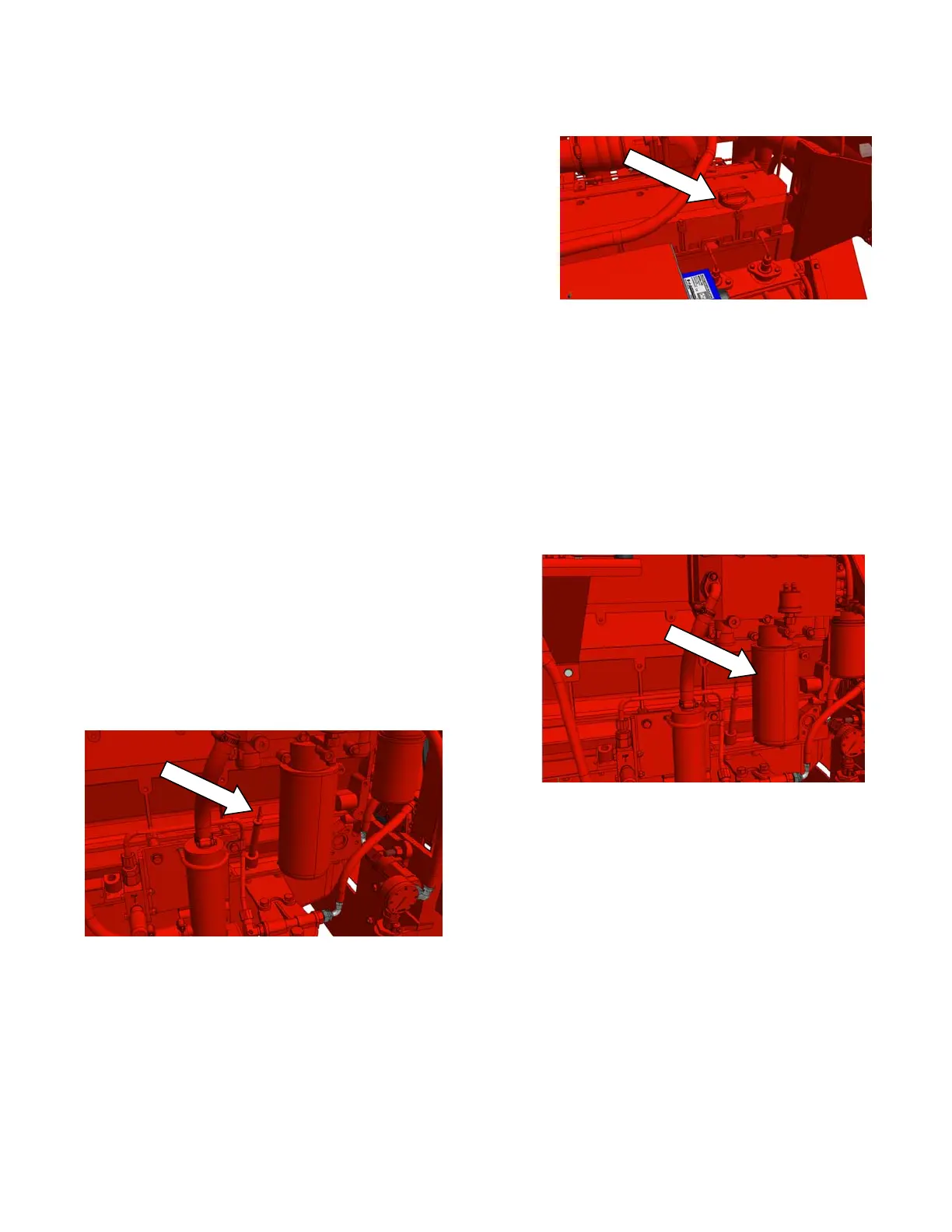

Check the sump oil level using the dipstick on the

engine as shown in Figures #18A and 18B.

This level must always be between the dipstick marks

Min. and Max. with the engine not running. On

DT2H engines the dipstick should be reinserted for

measurement very slowly so that the level on the

dipstick is accurate.

Figure #18A – ZF6H

3.3.2 Changing Engine Oil

1) Operate the engine until it is warm.

2) Stop the engine. Remove the sump drain

plug and drain the lubricating oil from the

sump. Fit the drain plug tighten the plug to

34 Nm (25.1lbf-ft) /3.5 kgf-m.

3) Fill engine with oil at the oil filler neck on

the valve cover. Check that the oil is at the

‘FULL” mark on the dipstick with new and

clean lubricating oil of an approved grade.

(see Figure 19D)

Figure #19D

4) Return the unit back into service by returning

the main pump controller selector to

“automatic”.

5) Dispose used oil properly.

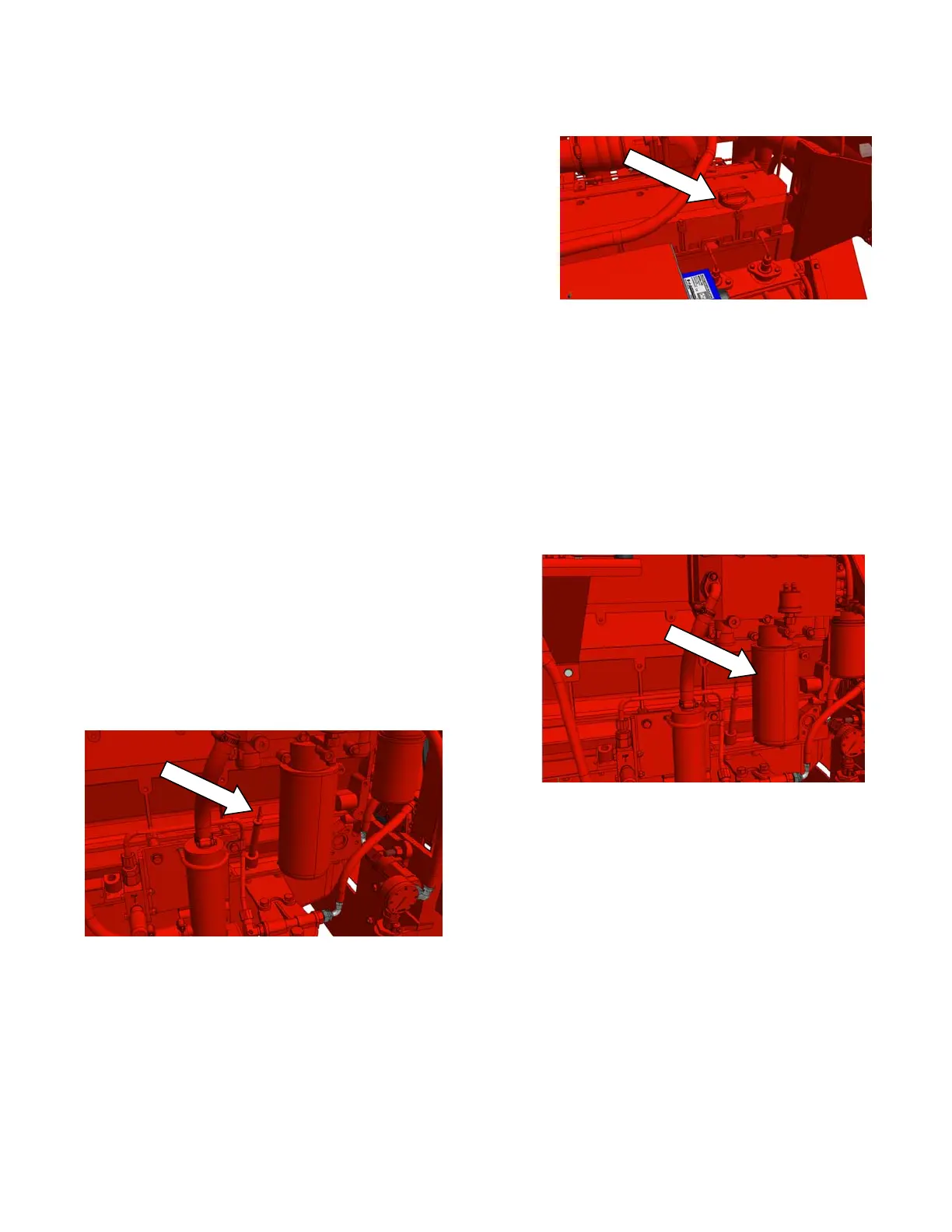

3.3.3 Changing Oil Filter Cartridge

1) Turn engine off.

2) Put a tray under the filter to retain spilt

lubricating oil.

Figure 14 - ZF6H

3) Remove the filter with a strap wrench or

similar tool. Then dispose of the filter

properly (Ref Figure #14).

4) Clean the filter head.

5) Lubricate the top of the filter seal with clean

engine lubricating oil.

6) Fit the new filter and tighten it until sealing

face is against the 0-ring. Turn 3/4 – 1 turns

further with the filter strap wrench.

7) Ensure that there is lubricating oil in the

sump. On turbocharged engines, ensure that

the engine will not start and operate the

starter motor until oil pressure is obtained.

8) Refer to alarm 5 of section 3.5.5 for over

crank/start disable instructions. Operate the

engine and check for leakage from the filter.

Loading...

Loading...