Page 27 of 41

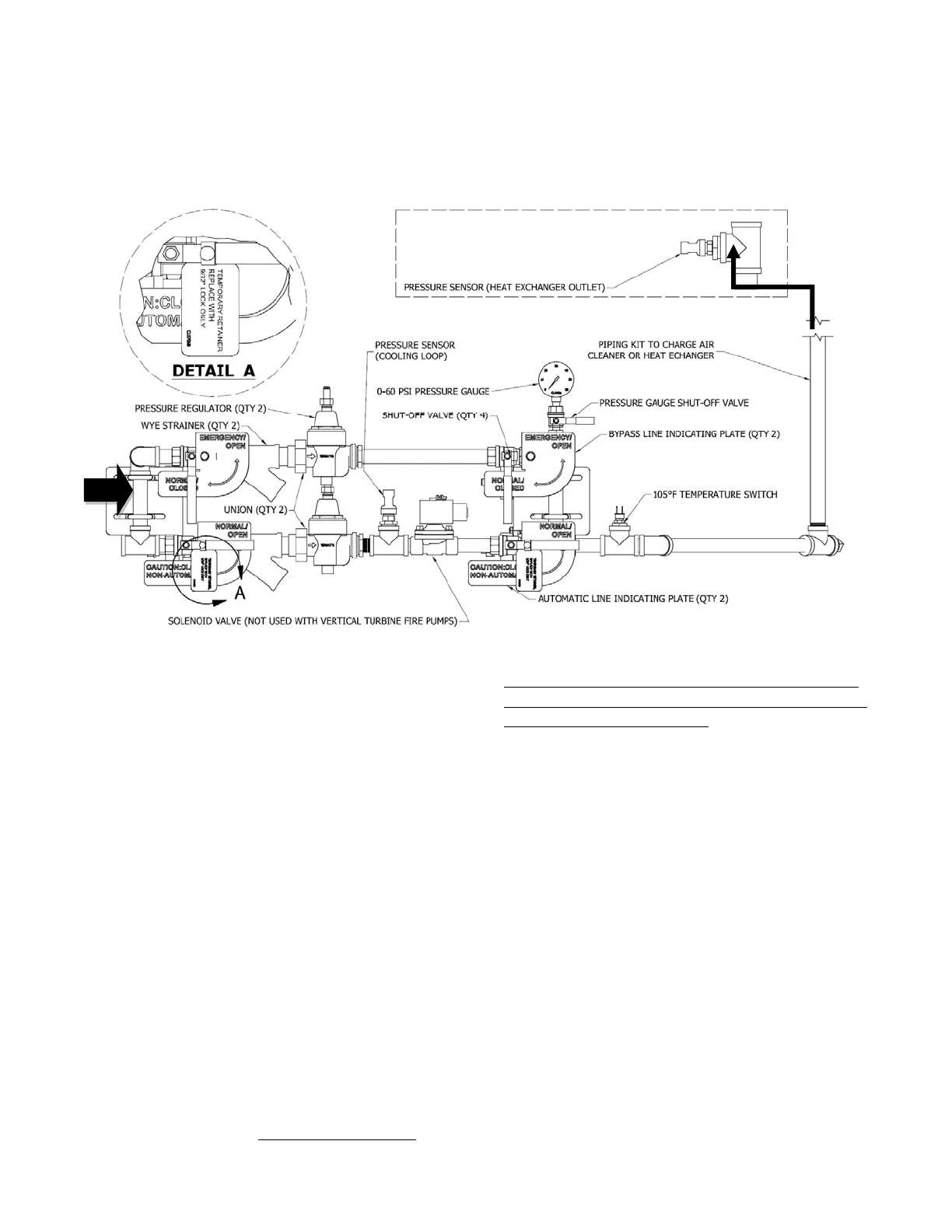

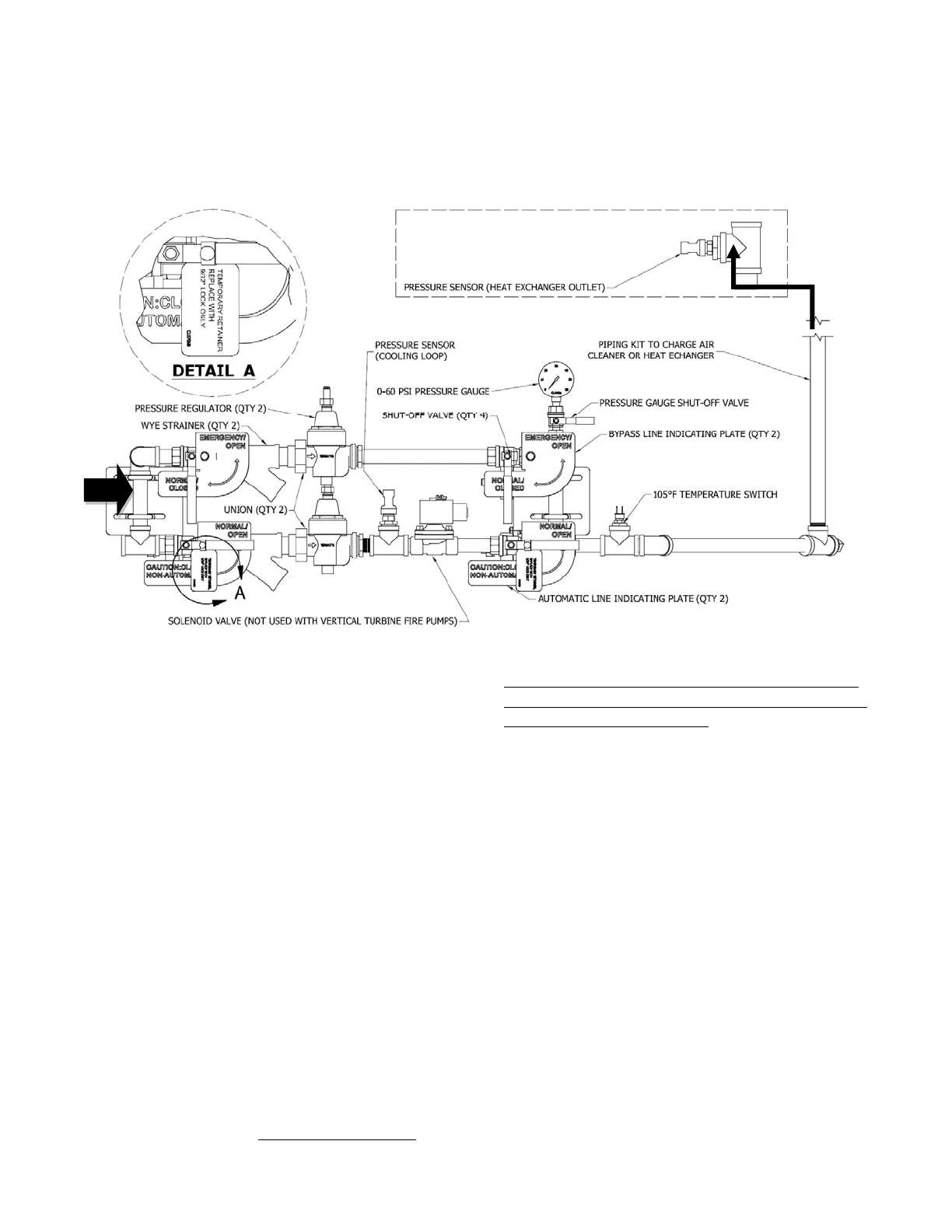

Figure #26

3.4.7.3 Setting Raw Water Flow Rate

The proper amount of raw water flow thru the engine

is of the utmost importance, and the pressure gauge

value does little to indicate if there is sufficient flow.

When the engine is exercised weekly, the amount of

raw water flow exiting the engine should always be

checked to verify it does not appear to have

diminished.

During initial commissioning of the engine, it is

important to correctly set the raw flow rate going thru

the cooling loop. Each Clarke engine model has an

Installation and Operation (I&O) Datasheet that

provides basic operating conditions of the engine and

most values are given based upon engine speed. You

will find this datasheet in the documentation bag that

is shipped with the engine for your specific Clarke

model. This datasheet must be available during

commissioning in order to set the proper minimum

raw water flow. With the fire pump flowing 150%

of rated flow, and the Automatic flow line open; set

minimum flow by using the adjusting screw at the top

of the pressure regulator. If proper cooling water

flow rate is established then no fire pump controller

alarm will be triggered to indicate clogged raw water

strainer (low raw water flow).

NOTE: To increase flow turn the adjusting screw

clockwise and to reduce flow turn the adjusting screw

counterclockwise. Do not exceed 60 psi on the

cooling loop pressure gauge!

You will need to capture the flow for a specific

amount of time coming out of the heat exchanger and

going to a floor drain in order to establish a

reasonably accurate flow rate value. Using a

container or bucket of known volume, record the time

required to fill the container and compare to the gpm

or L/min value provided on the I&O datasheet.

THIS IS CRITICAL FOR PROPER ENGINE

COOLING AT MAXIMUM PUMP LOAD! After

setting the pressure regulator in the Automatic

flowline, open the Manual by-pass line valves, and

then close the Automatic flowline valves and repeat

the above process in order to set the flowrate going

thru the pressure regulator in the Manual by-pass

line. Once this is completed; close the Manual by-

Loading...

Loading...