Page 14 of 41

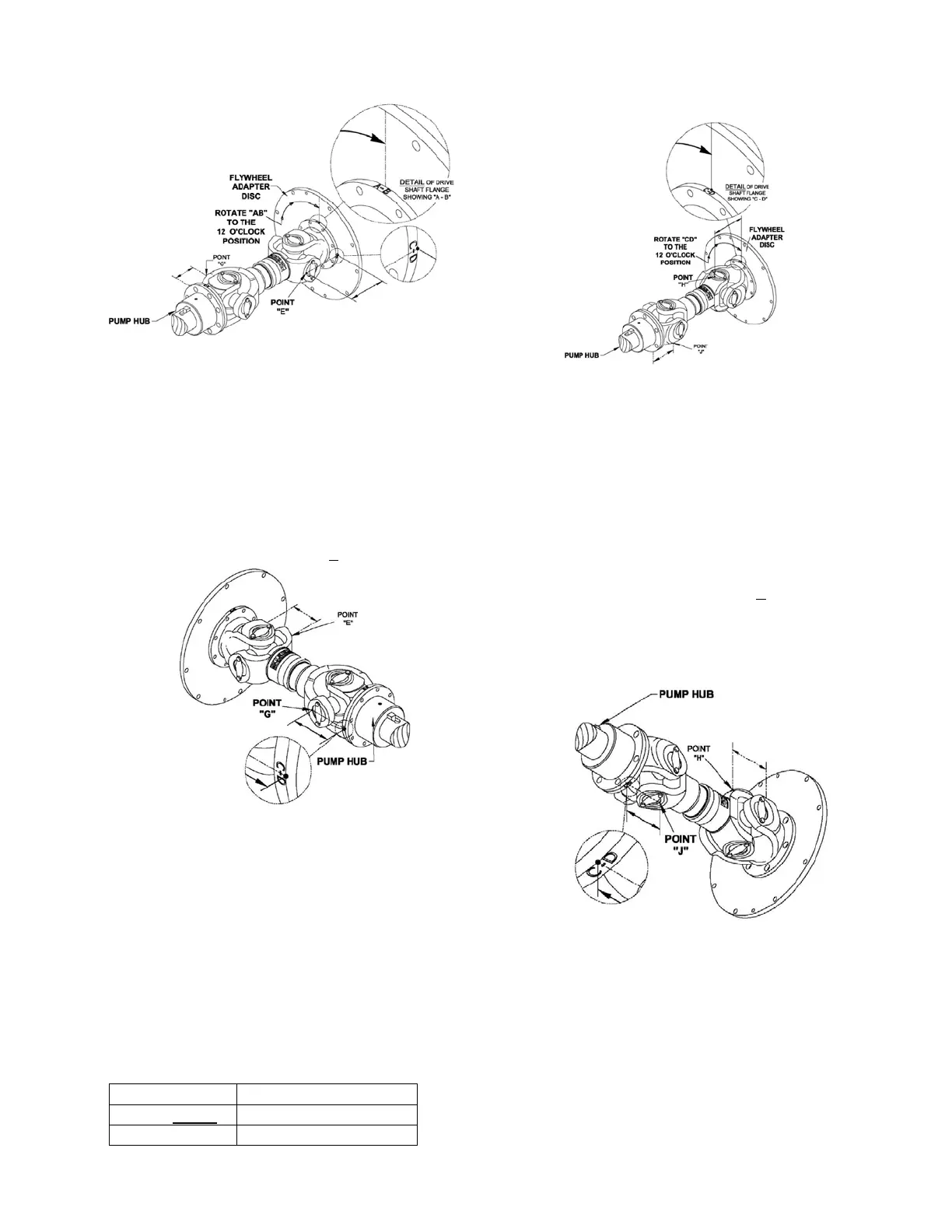

Figure #7a

B) With the driveshaft in the same orientation as

the previous step (Step A), check the

Horizontal Angular alignment of the shafts.

1. Measure from the mating surface of the

companion hub to point G shown on

figure #7b. (Point G is the furthermost

point on the bearing bore). This

measurement must be equal to the

measurement at point E + 0.5 mm.

Figure #7b

C) To check the Vertical Parallel Offset, the

driveshaft must be re-orientated.

1. Rotate the shaft 90

○

so the reference

“CD” on the flywheel adapter disc or the

circumference of the drive shaft flange

(against the flywheel) is in the position

shown on Figure#7c.

2. Measure from the face of the flywheel

adapter disc to point H. (Point H is the

furthermost point on the bearing bore

diameter). The measurement must be:

Measurement Driveshaft

70.5 ± 1 mm CDS20-S1

112.5 ± 1 mm SC81A / CDS50-SC

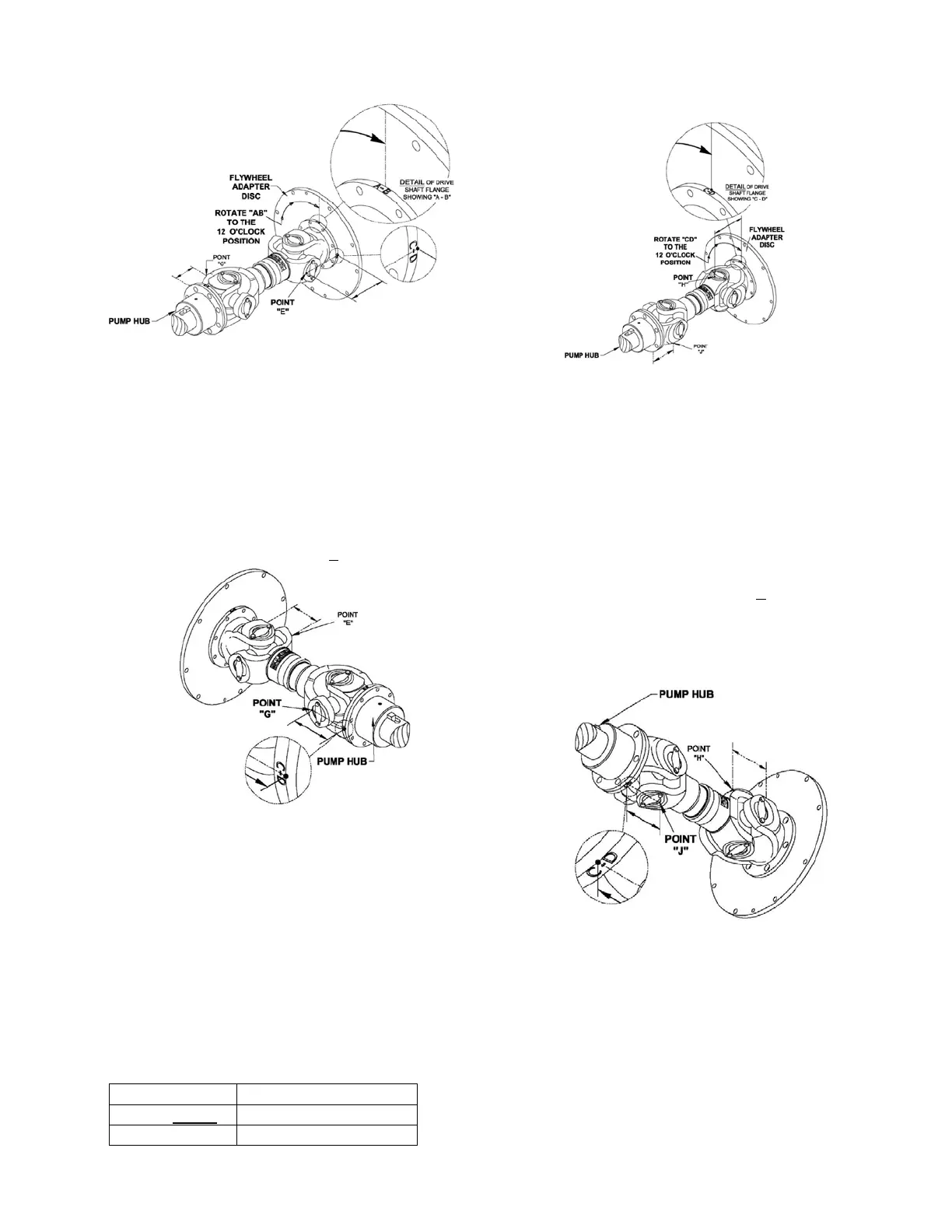

Figure #7c

D) With the driveshaft in the same orientation as

the previous step (Step C), check the Vertical

alignment of the shafts.

1. Measure from the mating surface of the

pump companion hub of the drive shaft

to point J as shown in figure #7d. (Point J

is the same as point G, with the

driveshaft rotated 90

o

). This

measurement must be equal to the

measurement at point H + 1 mm.

Re-install all guards and grease fittings before

reconnecting the battery cables.

Figure #7d

DRIVESHAFT MAINTENANCE

1. To service the driveshaft disconnect the

negative battery cables, remove the top of

guard an set aside.

2. Rotate engine shaft manually so the u-joint

grease fittings are accessible.

3. Using a hand held grease gun with N.L.G.I.

grade 1 or 2 grease position on grease fitting.

Loading...

Loading...