BOILER BOOK CFC-E ENGINEERING DATA

24

b) Independent from the hydraulics of the heating system, constant water circulation through each boiler is

required while the boiler is operating (requires a dedicated boiler pump if in a primary/secondary loop

arrangement). Refer to table below for minimum boiler circulation rates.

5) Minimum over-pressure at the boiler:

For outlet temperatures up to the maximum of 185 deg F (85 deg C), a minimum operating pressure of 30 psig

(2.1 bar) is required.

6) pH level should be maintained between 8.3 and 10.5

7) It is recommended to maintain continuous circulation in glycol systems. Where this is impractical (e.g. multiple

boiler systems), a periodic pump exercise routine should be implemented to ensure proper mixture of glycol and to

avoid degradation that naturally occurs with glycol mixtures. This can be as simple as opening a boiler isolation

valve once a day or turning on a boiler circulating pump.

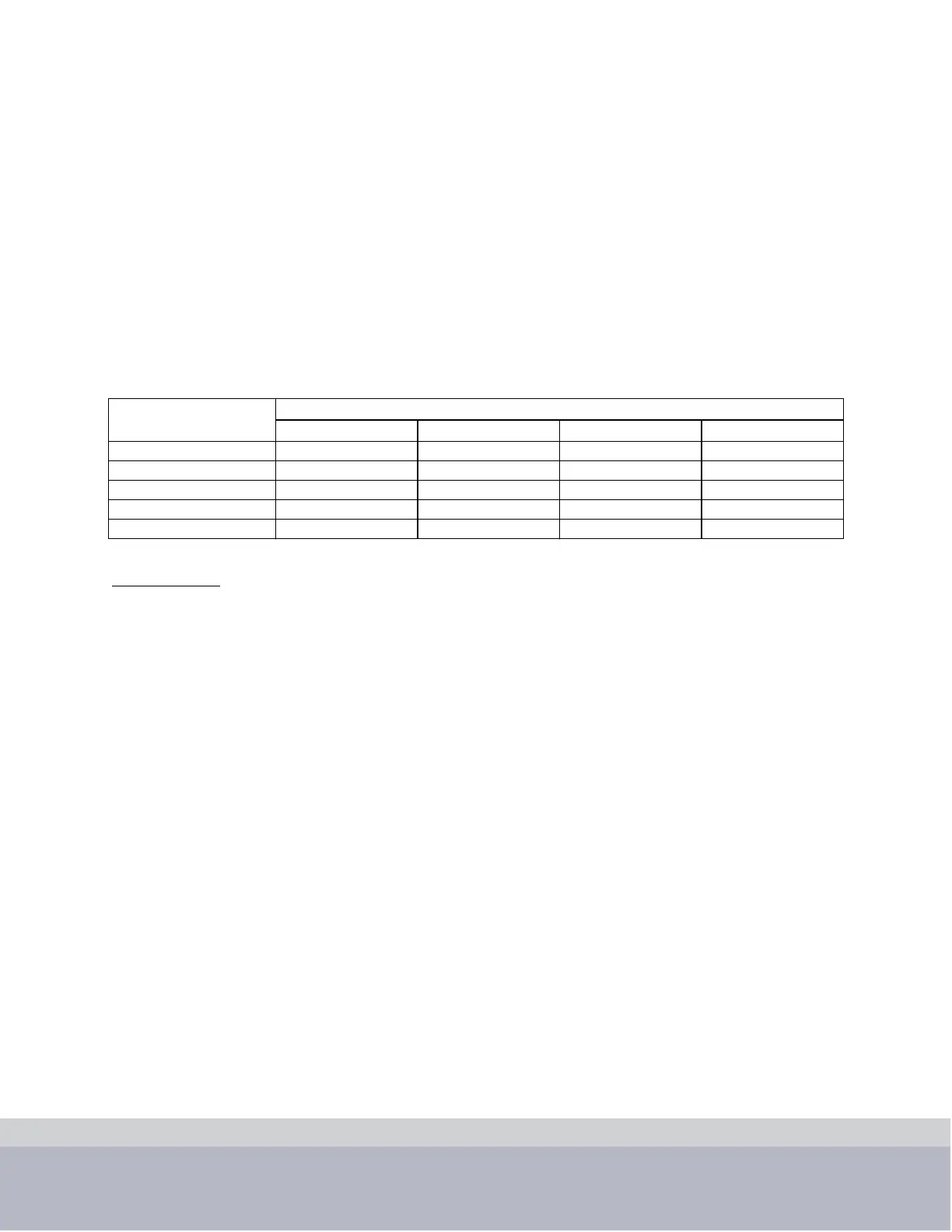

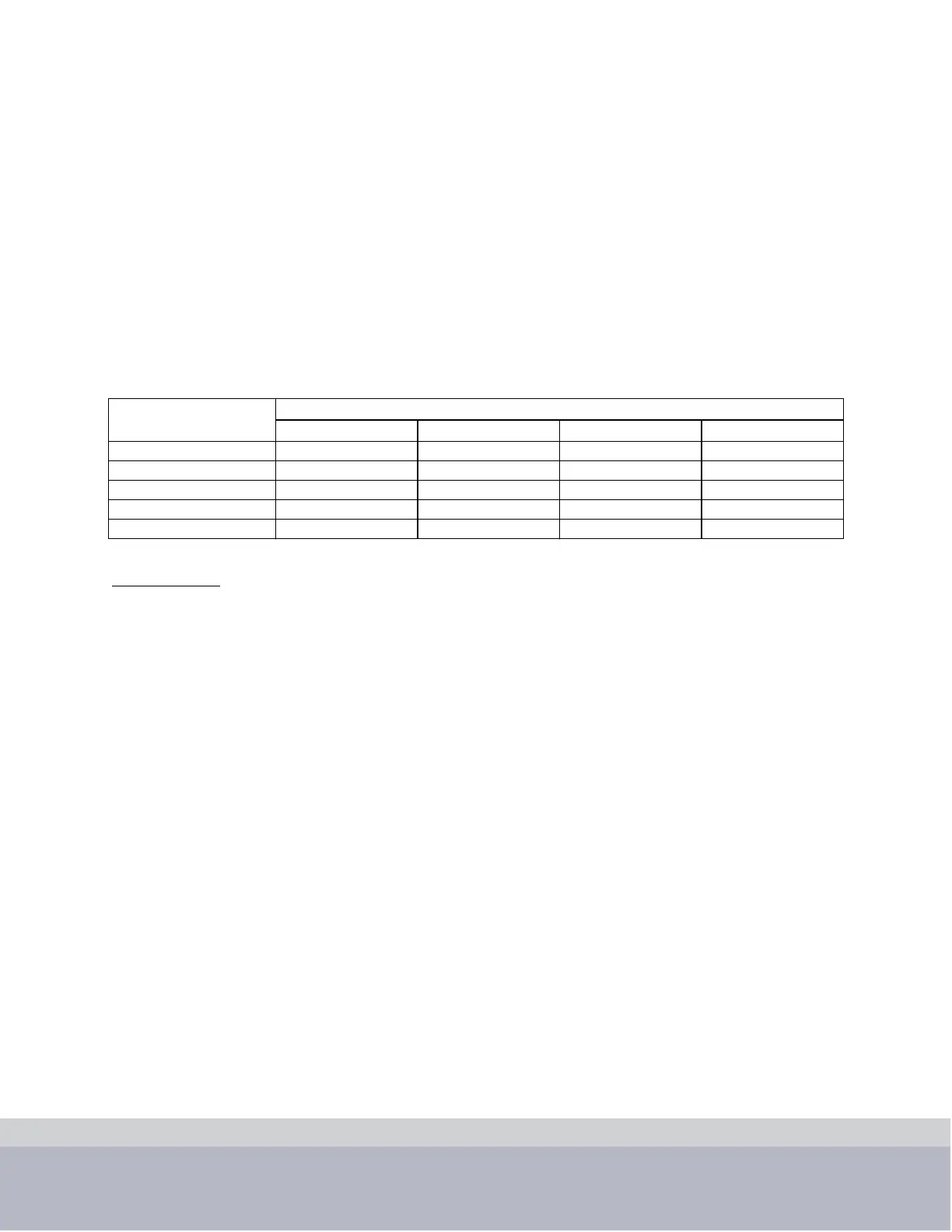

Table 12. Glycol Minimum Flow Recommendations for ClearFire Model CFC-E Boiler

(Minimum required boiler circulation rate (gpm) at maximum firing rate.)

Notes/Limitations:

1. Maximum firing rate determined by ClearFire CFC-E Glycol Firing Rate Limitation chart (below). Maximum high fire

blower speed set according to chart.

2. Glycol concentration of 25%-50%. Minimum required system operating pressure is 30 psig.

3. Maximum system operating temperature of 180 ˚F. Maximum ∆T of 40˚.

4. Circulation rates correlate with boiler output based on 92% nominal efficiency.

5. Standard altitude (<1000' ASL). Contact Cleaver-Brooks for high altitude applications.

6. Pumps should be sized based on system design ∆T and minimum required flow rates.

7. At minimum firing rate, the minimum circulation rate should correspond to the boiler's turndown.

System ∆T (˚F)

Model-Size

∆T = 10˚ ∆T = 20˚ ∆T = 30˚ ∆T = 40˚

CFC-E 500 95 47 32 24

CFC-E 750 142 71 47 36

CFC-E 1000 190 95 63 47

CFC-E 1500 285 142 95 71

CFC-E 2000 380 190 127 95

Loading...

Loading...