General Description Chapter 1

750-177 1-3

C. Construction

Steam boilers designed for 15 psig and hot water boilers designed for 250F at 160 psi or less are constructed

in accordance with Section IV, Heating Boilers, of ASME Code. Steam boilers designed for 150 psig are

constructed in accordance with Section I, Power Boilers, of the ASME Code.

D. Steam Controls (All Fuels)

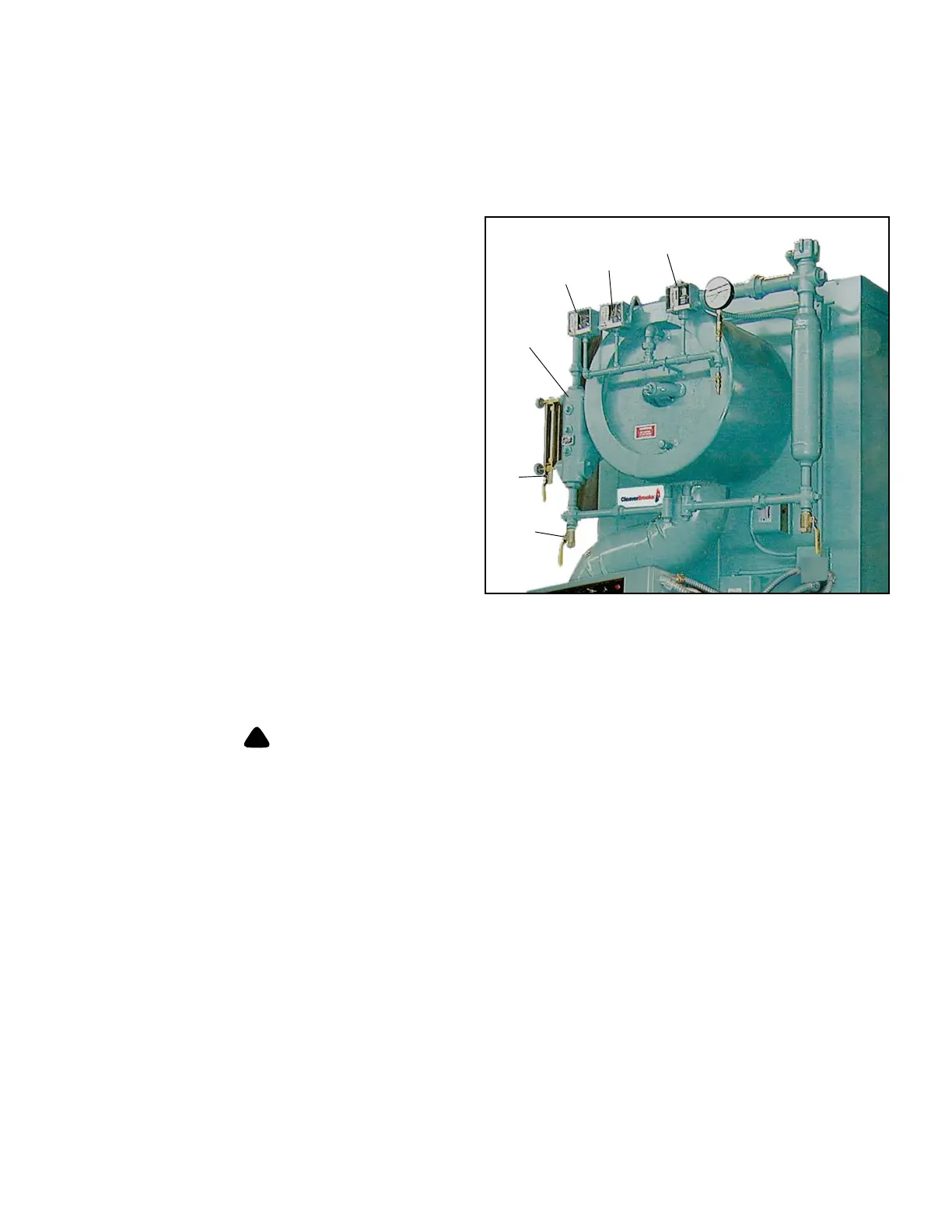

Figure 2-2: Steam Controls

1

2

3

4,5

6

7

1. High Limit Pressure Control: Breaks a circuit to

stop burner operation on a rise of pressure above a

selected setting. It is adjusted to stop the burner at

a preselected pressure above the operating limit

control setting. The high limit pressure control is

equipped with a manual reset.

2. Operating Limit Pressure Control: Breaks a circuit

to stop burner operation on

a rise of boiler pressure

at a selected setting. It is adjusted to stop or start

the burner at a preselected pressure setting.

3. Modulating Limit Pressure Control: Senses

changing b

oiler pressures and transmits the

information to the modulating motor to change the

burner firing rate when the manual-automatic

switch is set on “automatic.”

4. Low Water Cutoff and Pump Control: Float-

operated control

responds to the water level in the

boiler. It performs two distinct functions:

• Stops firing of the burner if water level lowers

be

low the safe operating point. Energizes the low-

water light in the control panel; also causes low-water alarm bell (optional equipment) to ring. Code requirements

of some models require a manual reset type of low-water cutoff.

• Starts and stops the feedwater pump (if used) to maintain water at the proper operating level.

Determine that the main and auxiliary low water cutoffs and pump control are level after installation

and throughout the equipment’s operating life. Failure to follow these instructions could result in

equipment damage.

5. Water Column Assembly: Houses the low-water cutoff and pump control and includes the water gauge glass and

gauge glass shutoff cocks.

6. Water Column Drain Valve: Provided so that the water column and

its piping can be flushed regularly to assist in

maintaining cross-connecting piping and in keeping the float bowl clean and free of sediment. A similar drain valve

is furnished with auxiliary low-water cutoff for the same purpose.

7. Gauge Glass Drain Valve: Provide

d to flush the gauge glass.

A

B

Loading...

Loading...