Chapter 1 General Description

1-4 750-177

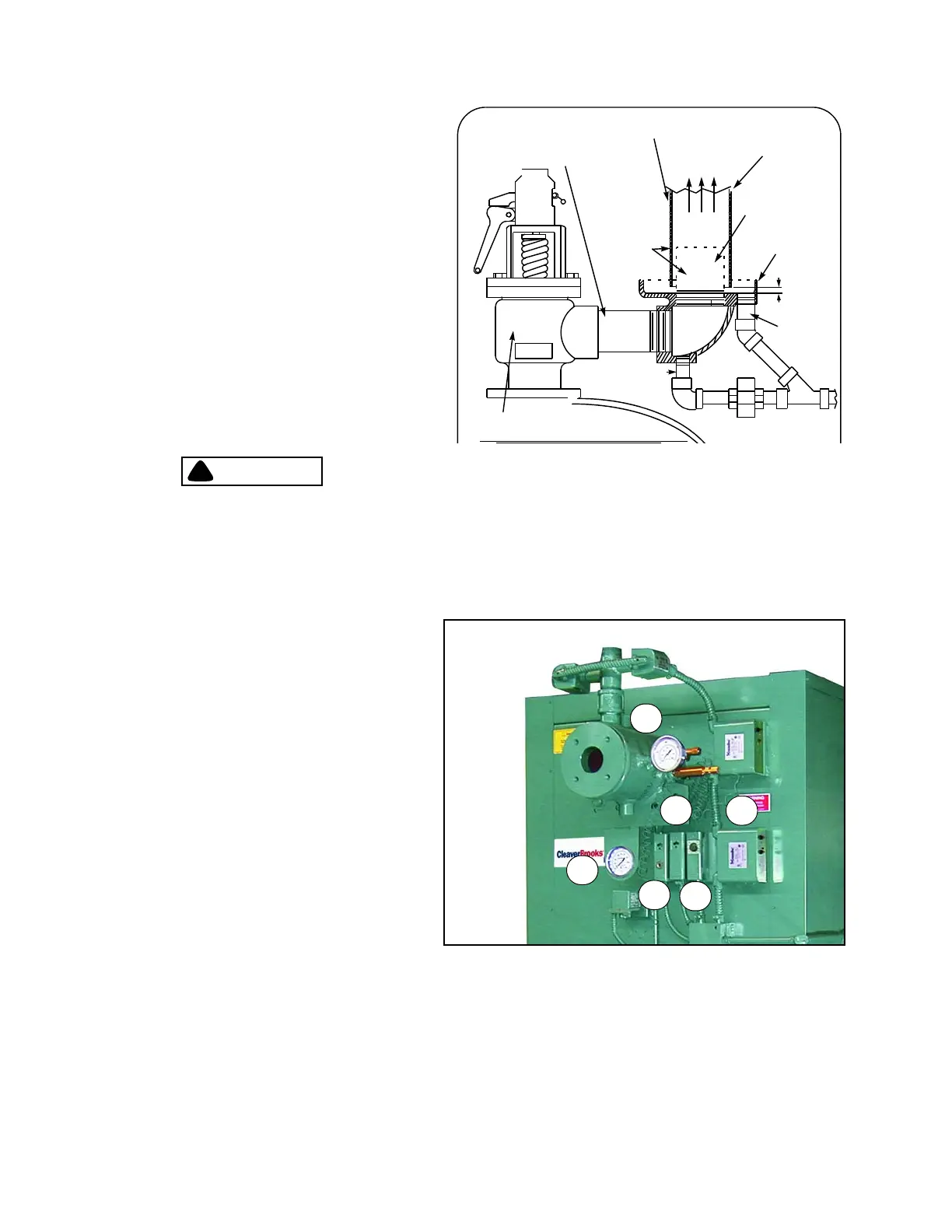

8. Safety Valve(s): Prevent buildup over the design

pressure of the pressure vessel. The size, rating and

number of valves on a boiler is determined by the

ASME Boiler Code. The safety valves and the discharge

piping are to be installed to conform to the ASME code

requirements. The installation of a valve is of primary

importance to its service life. A valve must be mounted

in a vertical position so that discharge piping and

code-required drains can be properly piped to prevent

buildup of back pressure and accumulation of foreign

material around the valve seat area. Apply only a

moderate amount of pipe compound to male threads

and avoid overtightening, which can distort the seats.

Use only flat-jawed wrenches on the flats provided.

When installing a flange-connected valve, use a new

gasket and draw the mounting bolts down evenly. Do

not install or remove side outlet valves by using a pipe

or wrench in the outlet.

DISCHARGE OPENING MUST BE

EQUAL TO OR LARGER THAN

INLET

CAUTION -

VENT PIPE

MUST NOT

TOUCH DRIP

PAN EXTEN-

SION

SUPPORT FROM BUILDING

CONSTRUCTION

VENT

DRIP PAN

EXTENSION

DRIP PAN

AND ELBOW

DRIP PAN

DRAIN

VENT PIPE

OPEN DRAIN

TO WASTE

BOILER SHELL

SAFETY VALVE

DRIP ELL DRAIN

WATER LEVEL

NOTICE: BACK-PRESSURE OF STEAM

EXHAUST SYSTEM MUST BE LESS THAN 6%

OF SAFETY VALVE SETTING.

TO STEAM

1 1/2”

MIN.

Figure 2-3: Recommended piping for steam relief

valve (not furnished by Cleaver-Brooks)

Only properly certified personnel such as the safety

valve manufacturer’s certified representative can

adjust or repair the boiler safety valves. Failure to

follow these instructions could result in serious

personal injury or death

E. Hot Water Controls (All Fuels)

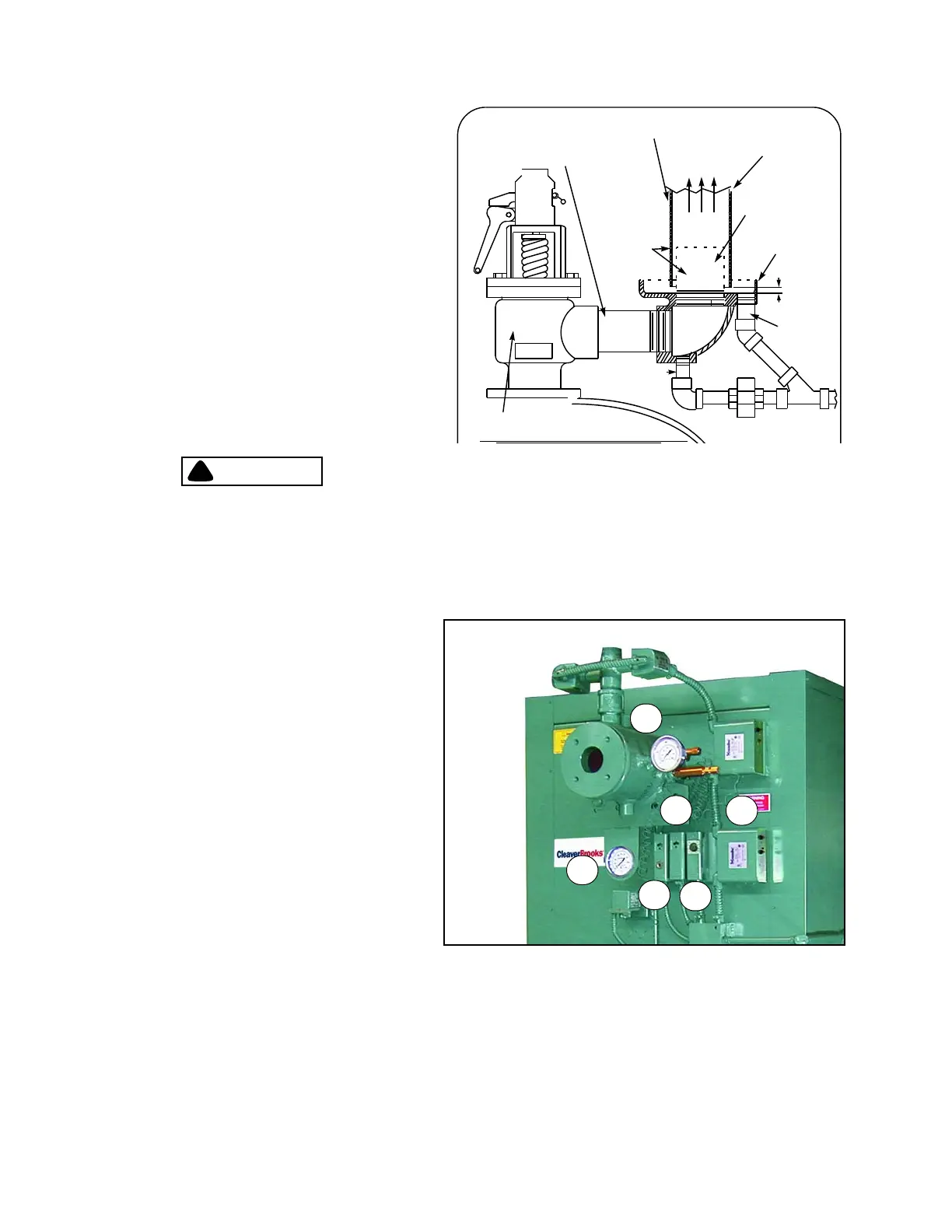

Figure 2-4: Hot Water Controls

1

2

3

4

5

6

1. Water Temperature Gauge: Indicates the boiler

internal water pressure.

2. Water Pressure Gauge: Indicates the internal

pressure of the

boiler.

3. High Limit Temperature Control: Breaks a circuit to

stop bu

rner operation on a rise of temperature at a

selected setting. It is adjusted to stop burner at a

preselected temperature above the operating control

setting. The high limit temperature control is

equipped with a manual reset.

4. Operating Limit Temperature Control: Breaks a

cir

cuit to stop burner operation on a rise of boiler

temperature at a selected setting. It is adjusted to

stop or start the burner at a preselected operating

temperature.

5. Modulating Temperature Control: Senses changing

boiler

water temperature and transmits the

information to the modulating motor to change the

burner firing rate when the manual-automatic switch

is set on “automatic.”

6. Low Water Cutoff: Breaks the circuit to s

top burner operation if the water level in the boiler drops below safe operating

point, activating low-water light and optional alarm bell if burner is so equipped.

Loading...

Loading...