39

Starting up the system

6 STARTING UP THE SYSTEM

6.1 Flushing the pipes

The refrigerant piping must be flushed with nitrogen to

remove dust, moisture and other particles that could

cause the compressor to malfunction if not eliminated

before the system is put into operation.

Flushing should be carried out after completing

connection of the piping, with the exception of final

connections to indoor units.

l

WARNING

Flushing must be performed before connecting

to indoor units.

a

CAUTION

Use only nitrogen for flushing. Do not use

carbon dioxide since it can create condensation

in the pipes. Oxygen, refrigerant, flammable

gases and toxic gases must not be used for

flushing. The use of such gases can cause fire

or explosion.

The flushing procedure is as follows:

1 Cover the inlets and outlets for the indoor units to

prevent dirt from being sucked inside during flushing

of the pipes.

2 Attach a pressure reducing valve to the cylinder of

nitrogen.

3 Connect the outlet of the pressure reducing valve to

the inlet on the liquid (or gas) side of the outdoor unit.

4 Use blanking plugs to block all openings on the liquid

(gas) side except for the opening on the indoor unit

(N) which is farthest from the outdoor unit.

5 Begin to open the valve of the cylinder of nitrogen

before gradually bringing the pressure to 0.5bar.

6 Allow the nitrogen to flow to the opening of the indoor

unit (N).

7 Clean the opening with a cloth until no more dirt or

moisture comes out. Check with a clean cloth that the

opening is clean.

8 Seal the opening

Repeat steps 7 and 8 for all the outlets of the indoor units,

from the furthest to the closest to the outdoor unit.

9 Seal all the openings.

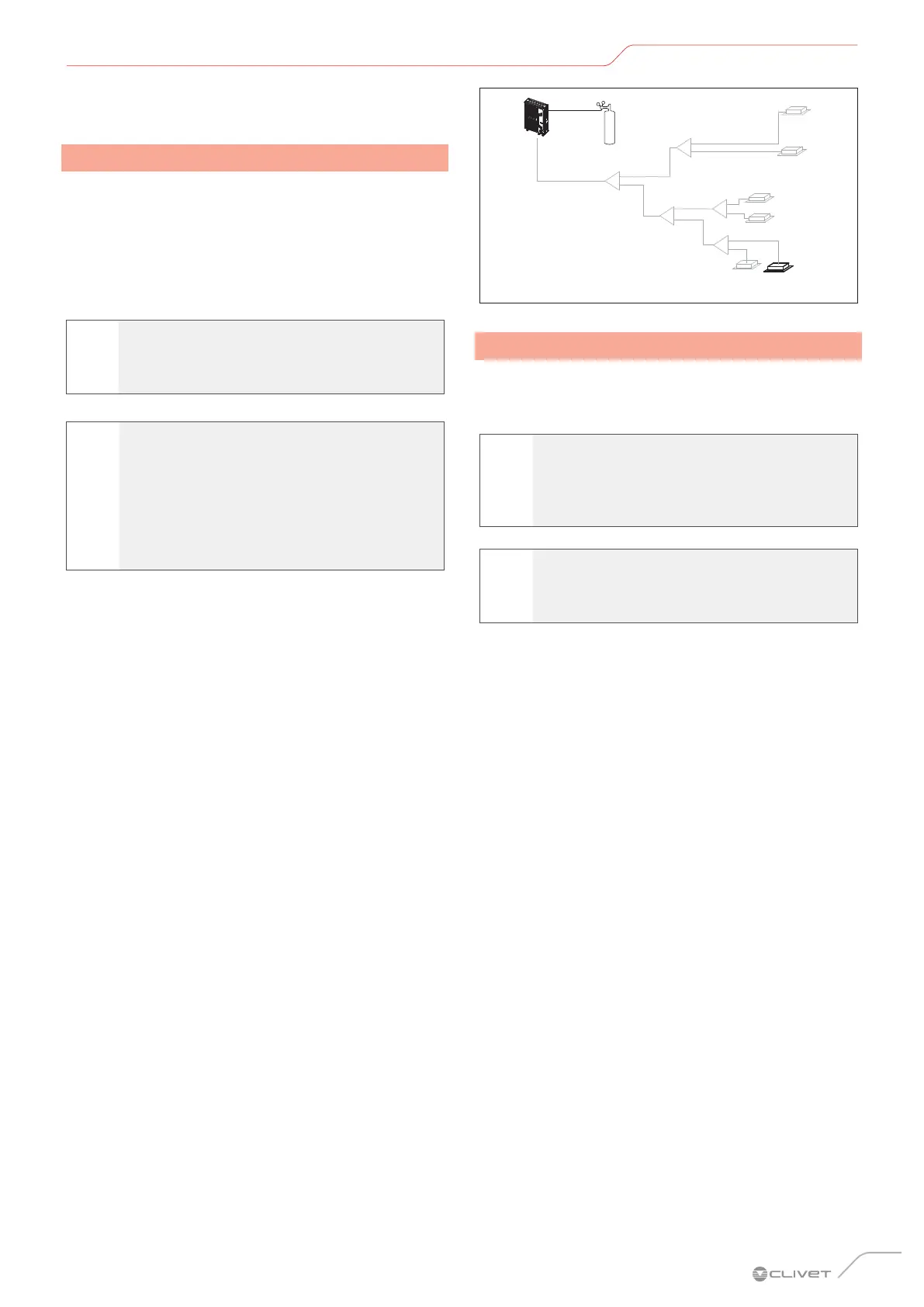

L

1

L

2

N

1

N

2

N

3

N

5

N

6

N

4

L

3

L

4

L

5

a

A

B

D

E

C

b

c

e

f

d

Fig. 63

6.2 Gas leak test

A leak test must be carried out before the system is put

into operation, in order to avoid failures caused by the

leaking of refrigerant.

a

CAUTION

Use dry nitrogen only. Do not use oxygen,

flammable gases and toxic gases. The use of

such gases can cause fire or explosion.

m

CAUTION

Make sure that all the stop valves of the

outdoor unit are closed tightly.

– Connect the outdoor unit and indoor units and

create a vacuum in the piping at -0.1Mpa.

A vacuum pump with a minimum capacity of 80-120 litres/

minute is required for vacuum operations.

If the required value is not reached, it is recommended to

carry out further drying using the triple vacuum procedure.

– Fill the internal piping with nitrogen at 0.3Mpa via

the needle valve of the liquid stop valves (3). Leave

to act for at least 3 minutes.

Do not open the liquid (1) or gas (2) stop valves. Observe

the pressure gauge to check for significant leaks. If there

is such a leak, the hand of the pressure gauge will go

down rapidly.

– Fill the system with nitrogen at 1.5Mpa and leave to

act for at least 3 minutes.

Observe the pressure gauge to check for small leaks. If

there is such a leak, the hand of the pressure gauge will

go down rapidly.

– Fill the system with nitrogen at 4.0Mpa and leave

to act for at least 24 hours.

– Write down the initial room temperature (Ti).

A change in the room temperature of 1°C corresponds to

a change in the pressure of the nitrogen charged in the

line of 0.01MPa (0.1bar). Use this correction factor when

comparing the final room temperature (Tf) with the initial

one (Ti).

Loading...

Loading...