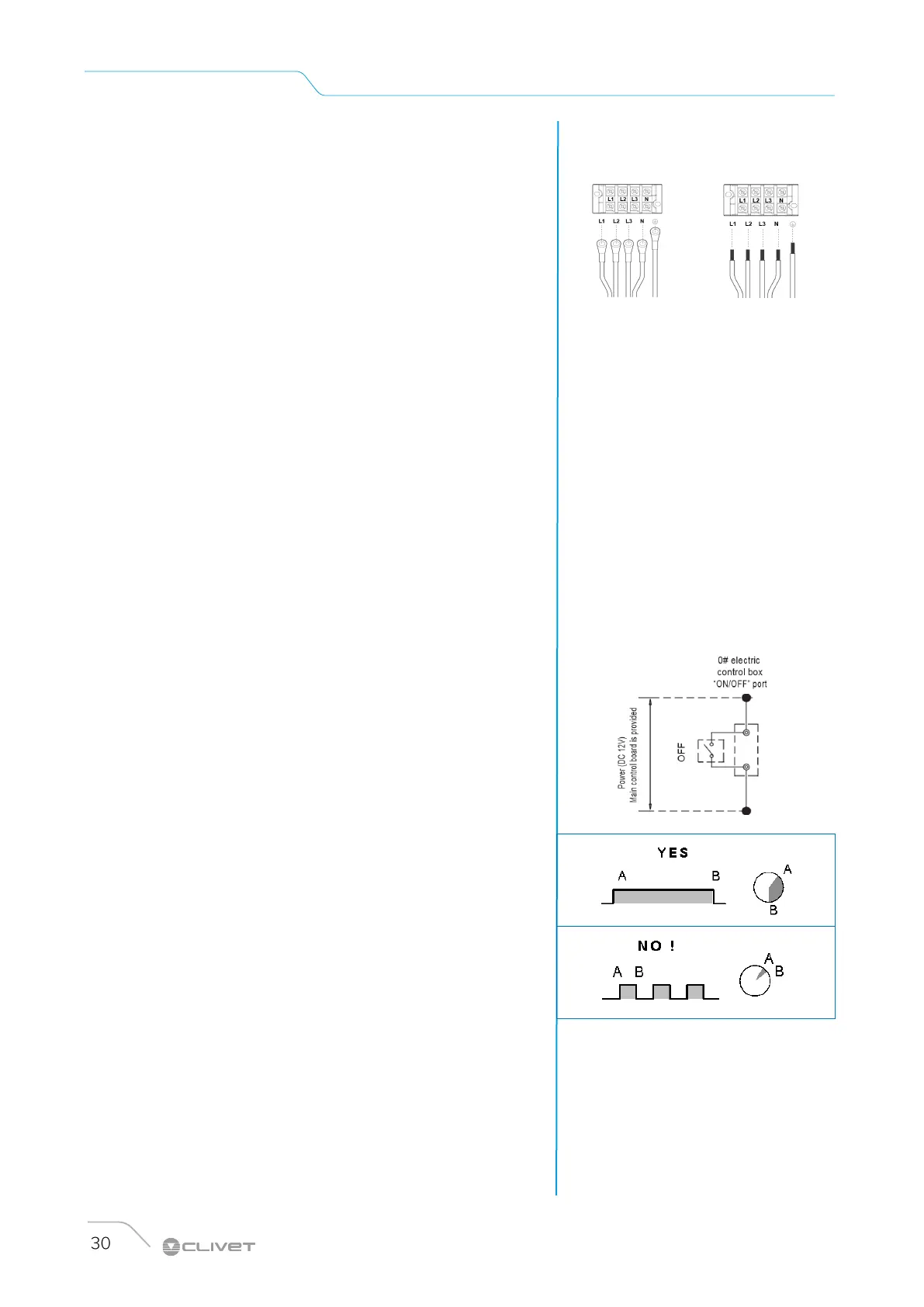

Electric line input

Fix the cables: if vacated, they may be subject to tearing.

The cables must not touch the compressor and the refrigerant

piping ( they reach high temperatures ).

Use eyelet wire terminals.

If the length of the cable exceeds the value specified in the chart

or if the voltage drop exceeds the threshold, increase the section

of the power supply cable in compliance with relevant regulation.

The lightning rod and unit earthing cables must be separate.

Signal lines

Use shielded cables. Any other cable may produce an

interference that will cause malfunctioning of the unit.

The screen must be connected to earth without interferences.

Guarantee the continuity of the screen during the entire extension

of the cable.

Do not exceed the maximum distance allowed.

Lay the cables away from the power lines with a different voltage

or that emit interferences of electromagnetic origin.

Avoid laying other cables in a parallel manner. Crossing with

other cable is only allowed if at 90°.

In case of parallel power supply and signal cables, use separate

metal ducts. Minimum distance between power supply and signal

cables:

300 mm for absorption up to 10A.

500 mm for absorption up to 50A.

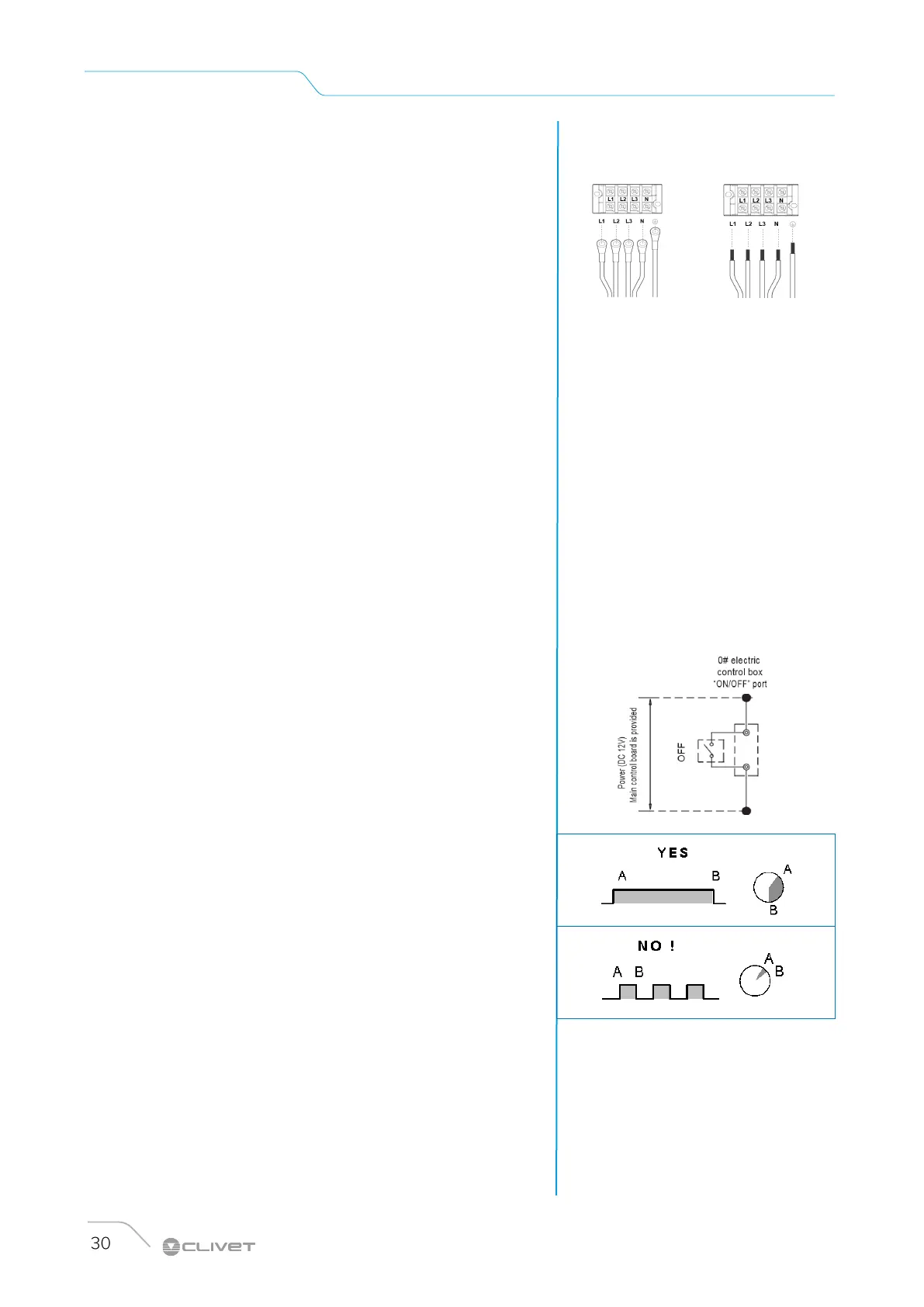

Remote ON - OFF

To enable the remote On-Off, set DIP switch S5-3 on ON.

With the units in modular configuration, remote control must be

applied to the master unit, which transmits it to the slave units.

After setting up the S5-3, interrupt and reconnect the voltage to

activate the modification.

This way, the controller function is disabled.

Connect the remote control to inlet: XT2 15 - 24

Do not perform short On-Off cycles

Do not use the remote On-Off with a thermoregulation function.

Flow switch - SW WATER

Factory wiring

Double setpoint - SW TEMP

Refer to page 58 to enable the function.

OK NO

Loading...

Loading...