15

Using method:

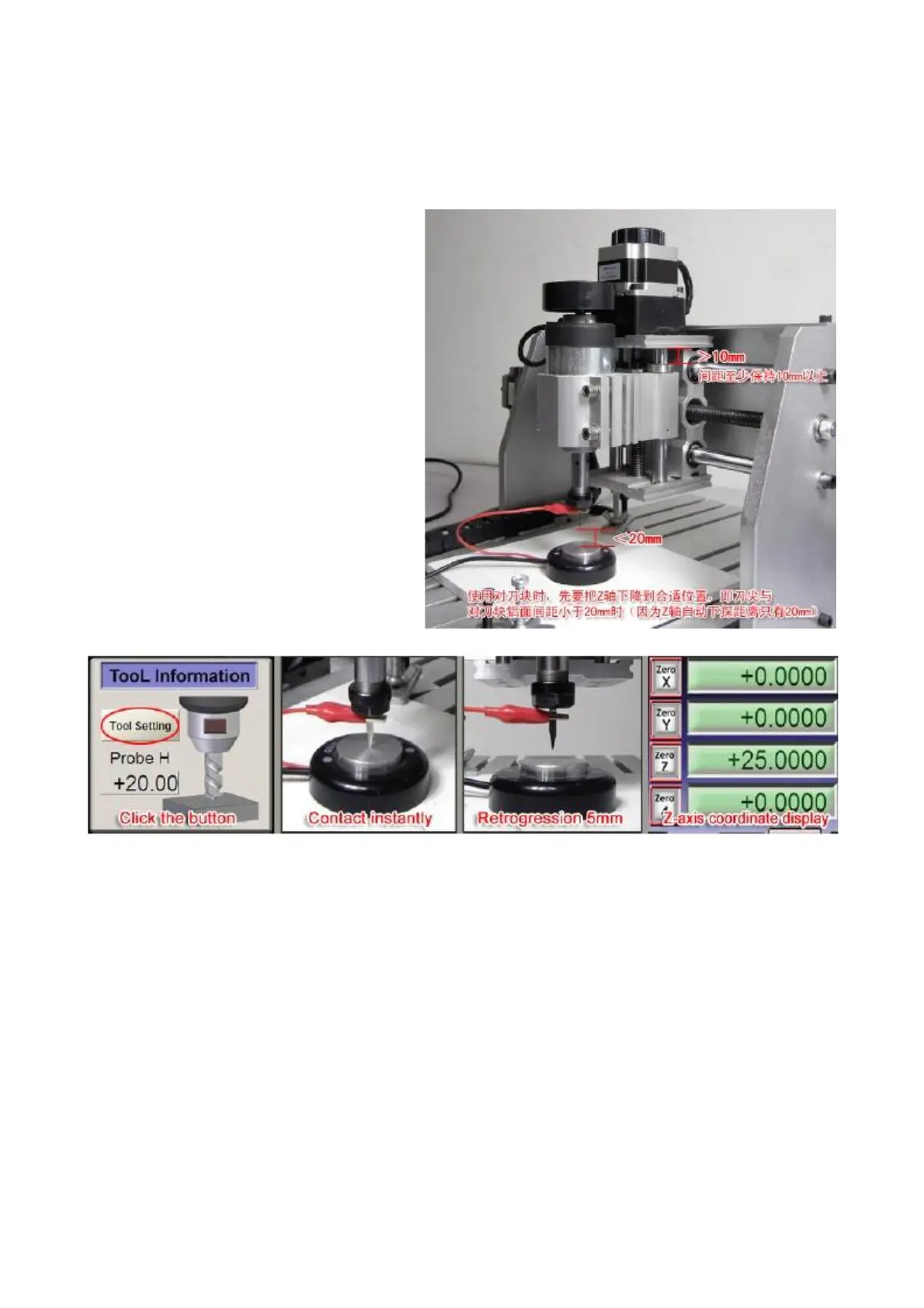

① Just shown in the picture, put the tool setting gauge on the materials to be engraved, and then adjust

Z axis to an appropriate position manually. When the tool setting is triggered, Z axis may arise 5mm

automatically; when it is executing the task of tool setting, the automatic bottom detection distance for Z

axis is only 20mm. Therefore, at the time of

making manual adjustment, the distance

between the tool tip and the surface of the

tool setting gauge should be no more than

20mm. After adjustment, the tool shank

should be clipped by the clams on the red

cable.

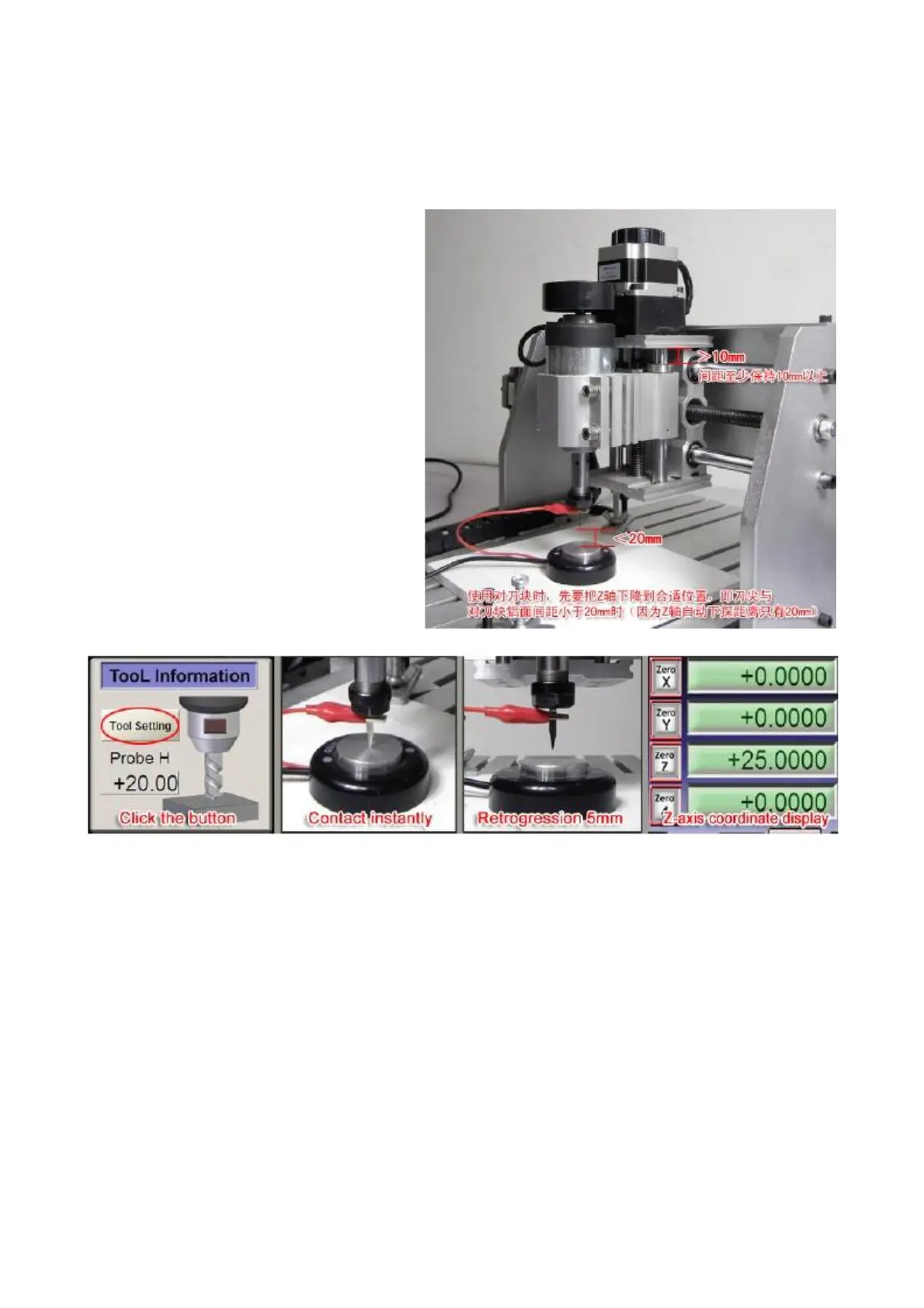

② Turning on the POWER switch on the

control box, and clicking the "Tool Setting"

button in the MACH3, Z axis may slowly

decline. When the tool tip touches the

surface of the tool setting gauge, it may

immediately stop, and then automatically

return upward 5mm.

③ Take away the tool setting gauge, and then the tool setting is completed. Attention that the

coordinate data on the Z axis should not be zero at this time.

◆Control the spindle motor through software

This machine supports MACH3 software to control the start, stop, and speed regulation of the principal

axis. Meanwhile, you may also directly add the code to start or close the principal axis in the engraving

code, so as to make the principal axis starts automatically and reach to the preset rotational speed at

the beginning of engraving. When the engraving is finished, the principal axis may be automatically

closed (recover the minimal rotational speed). Now, let's learn the method of controlling the spindle

motor by software.

Loading...

Loading...