BOLTS, NUTS and HARDWARE

CHECK torque on all bolts, nuts and

hardware like shake motor. The shaking

action of the head causes vibration and

can loosen these items. Failure to IN-

SPECT can result in damage.

CLAMP SYSTEMS

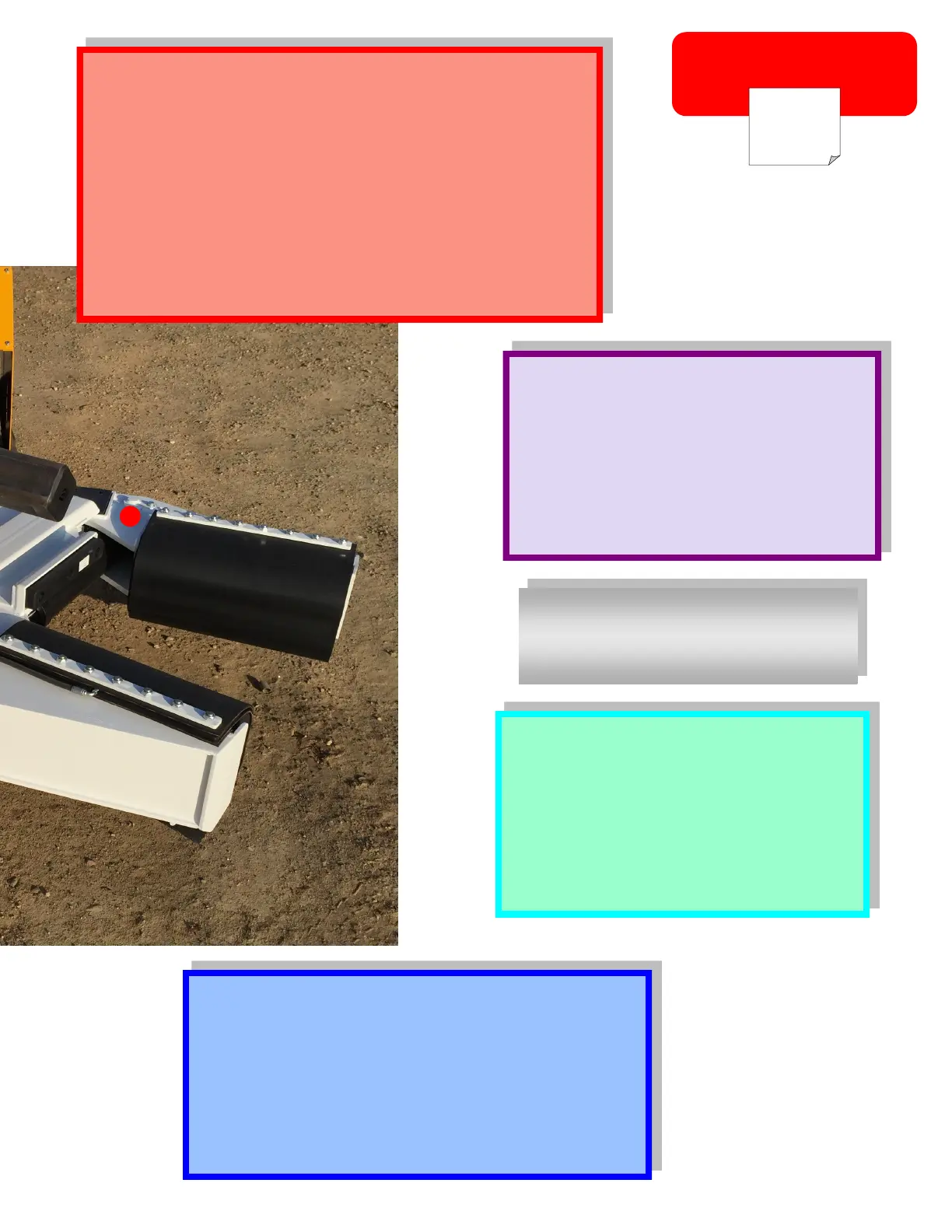

CYLINDER Inspect clamp cylinder,

pins, and bushings regularly. Grease Dai-

ly.

WEAR PLATES Periodically check

wear plate thickness. Replace if worn to

prevent damage to clamp arm pin.

Service

16

TREE PROTECTION SYSTEMS

SHAKER PADS Keep in good repair and re-

place if cracked , worn or deformed.

SLING Replace worn or damaged slings.

WATER MANIFOLD Periodically check flow

from 4 ports to make sure flow is equal.

FLAP Replace flap when worn or damaged.

CLAMP SYSTEMS

CYLINDER Inspect clamp cylinder, pins, and bush-

ings regularly. Grease Daily.

WEAR PLATES Periodically check wear plate thick-

ness. Replace if worn to prevent damage to clamp arm

pin.

CLAMP HOSES Regularly check clamp hoses and

brackets on inside of case for wear or loose hardware

that can come loose from shaking.

CLAMP ARM PIN Regularly check clamp pin torque.

Adjust clamp arm toque as needed to prevent wear.

SLING STUDS

STUDS Replace studs if broken.

Check torque regularly.

NUTS Keep nuts tight.

RETAINER BAR Replace sling bar if

bent to prevent tree damage.

TH-7 Shaker Head

Service Points

Loading...

Loading...