CALOR 40 Manual Page 10 (total 27) COMAC CAL s.r.o.

Tightening is necessary to be done three times; for the first time to 50% of max. torque as per

the table above. For the second time, to 80% and for the third time, to 100% of the max.

torque.

It is recommended to check the tightening of the bolts approx. 24 hours after the meter has

been installed.

When the flow sensors over 200 mm are installed, it is essential to observe, apart from the

above mentioned rules, also simultaneous tightening of the parallel screws on both counter

flanges to prevent the electrodes or the measuring tube from possible injury (symmetrical

stretching of the lining).

Grounding

Each of the flow meters must be perfectly and effectively grounded. The grounding line must

not transfer interference voltage, therefore, this line must not be used simultaneously for

grounding other electric meters.

The flow sensor is equipped with a stainless grounding screw with washer and nut for the

grounding cable being delivered with mounting accessories. This must be conductively

connected with the counter flanges. If it is not ensured that the counter flanges are in direct

contact with the measured liquid and they are conductive, it is essential to apply grounding

rings, see hereinafter.

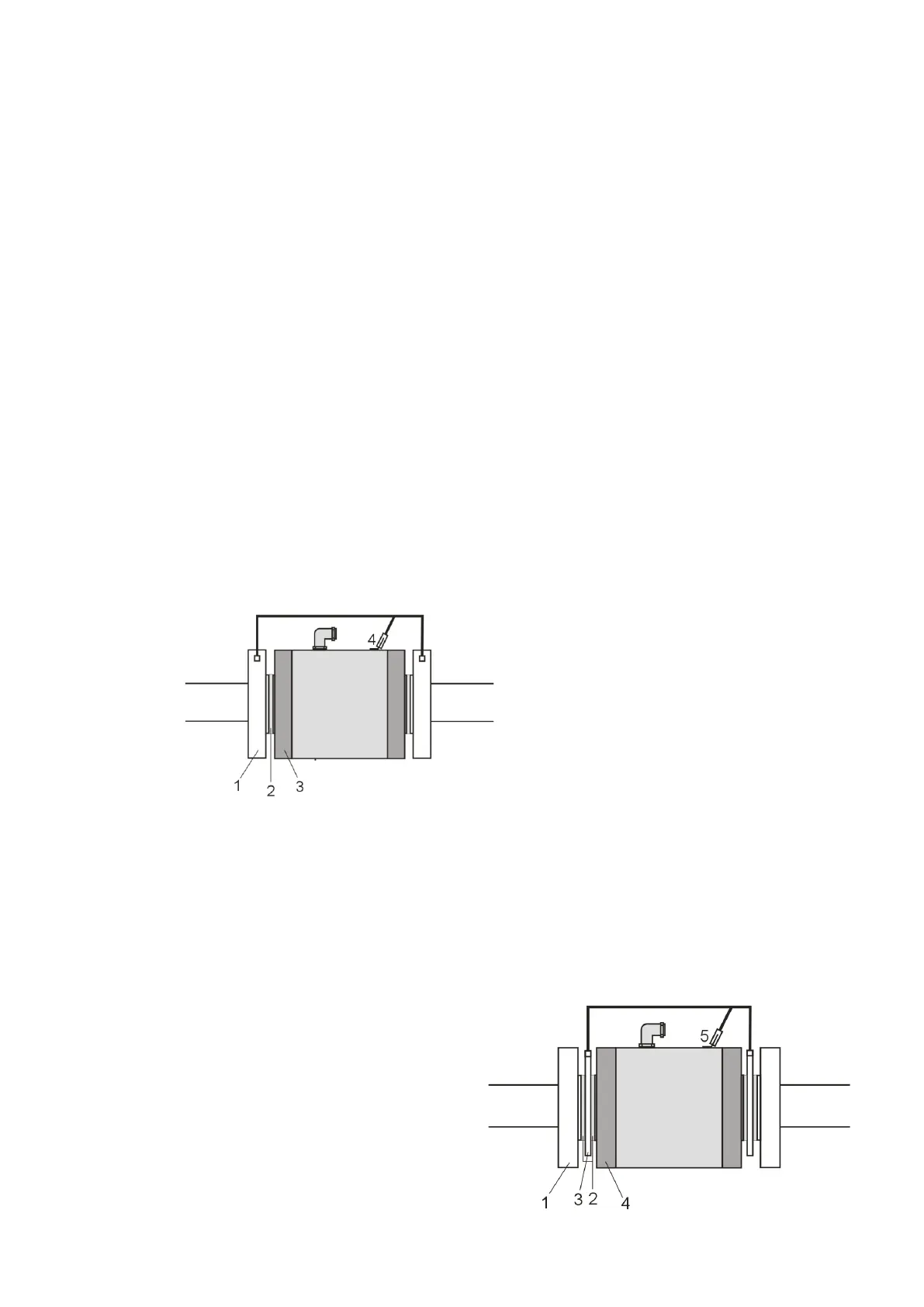

1 – opposite flange

2 – seal

3 – sensor

4 – grounding connector

Grounding rings

Only if they are ordered. They are applied for plastic or metal pipes with the inside layer for

the measuring tube elevated or put out onto the faces of the flow sensor. The conductive rings

made of stainless steel provide conductive connection with the measured fluid.

The flow sensor is furnished with a stainless grounding screw for the grounding cable being

delivered with mounting accessories. This must be conductively connected with the

grounding rings.

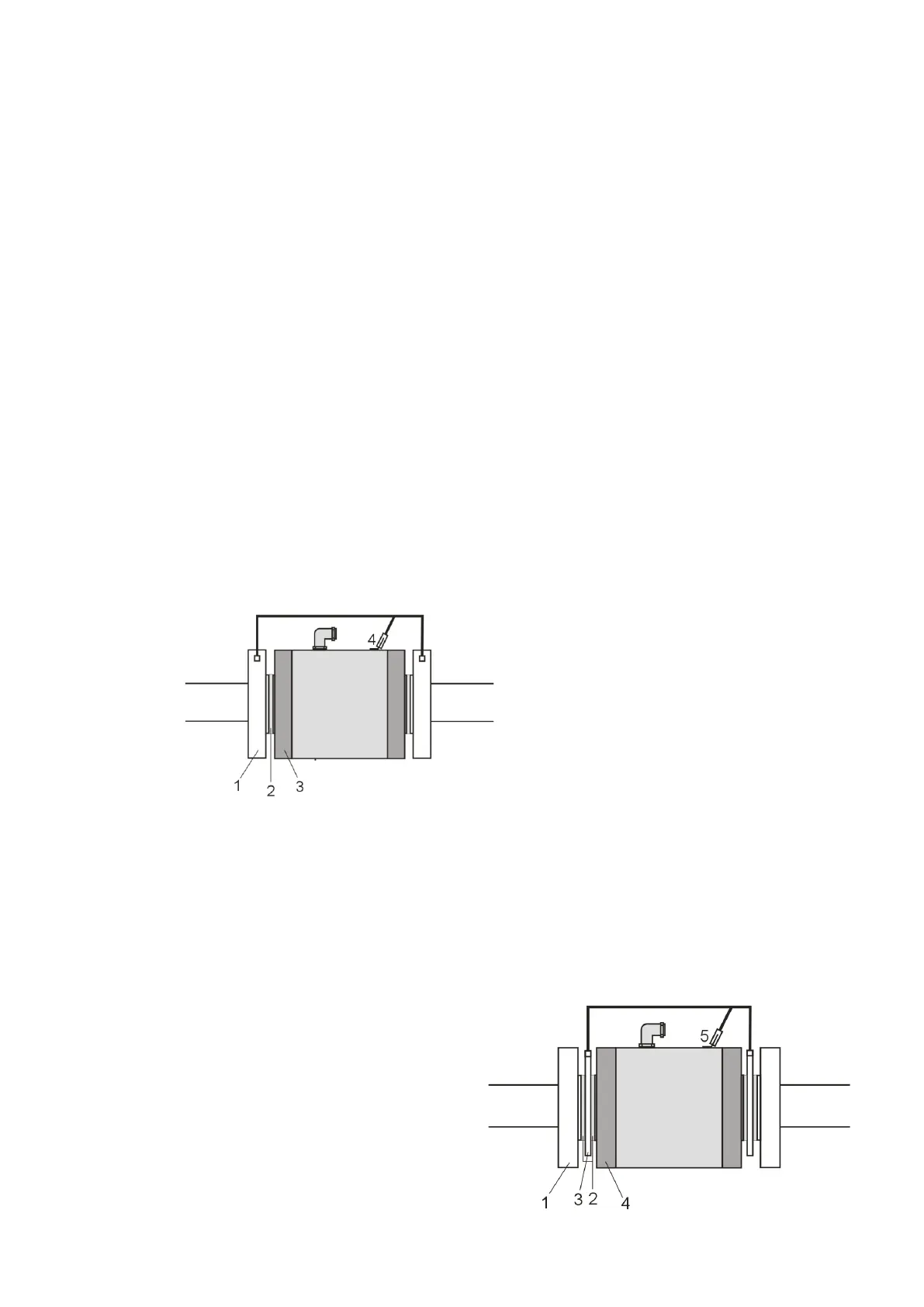

1 – opposite flange

2 – seal

3 – grounding ring

4 – sensor

5 – grounding connector

Loading...

Loading...