CALOR 40 Manual Page 9 (total 27) COMAC CAL s.r.o.

When a threaded connection is used, it is essential to check the thread on the sensor, while it

is being tightened, to prevent it from moving round a slight amount.

Avoid during the installation:

- Dropping the meter on the floor and causing injury especially to the ceramic

measuring tube.

- Contamination of electrodes (do not touch the electrodes as contamination occurs).

- Using any additional seal so as to prevent it from extending to the flow profile of the

sensor between its flanges and the pipe, otherwise the error in flow measurement

may be increased.

Tightening torque values

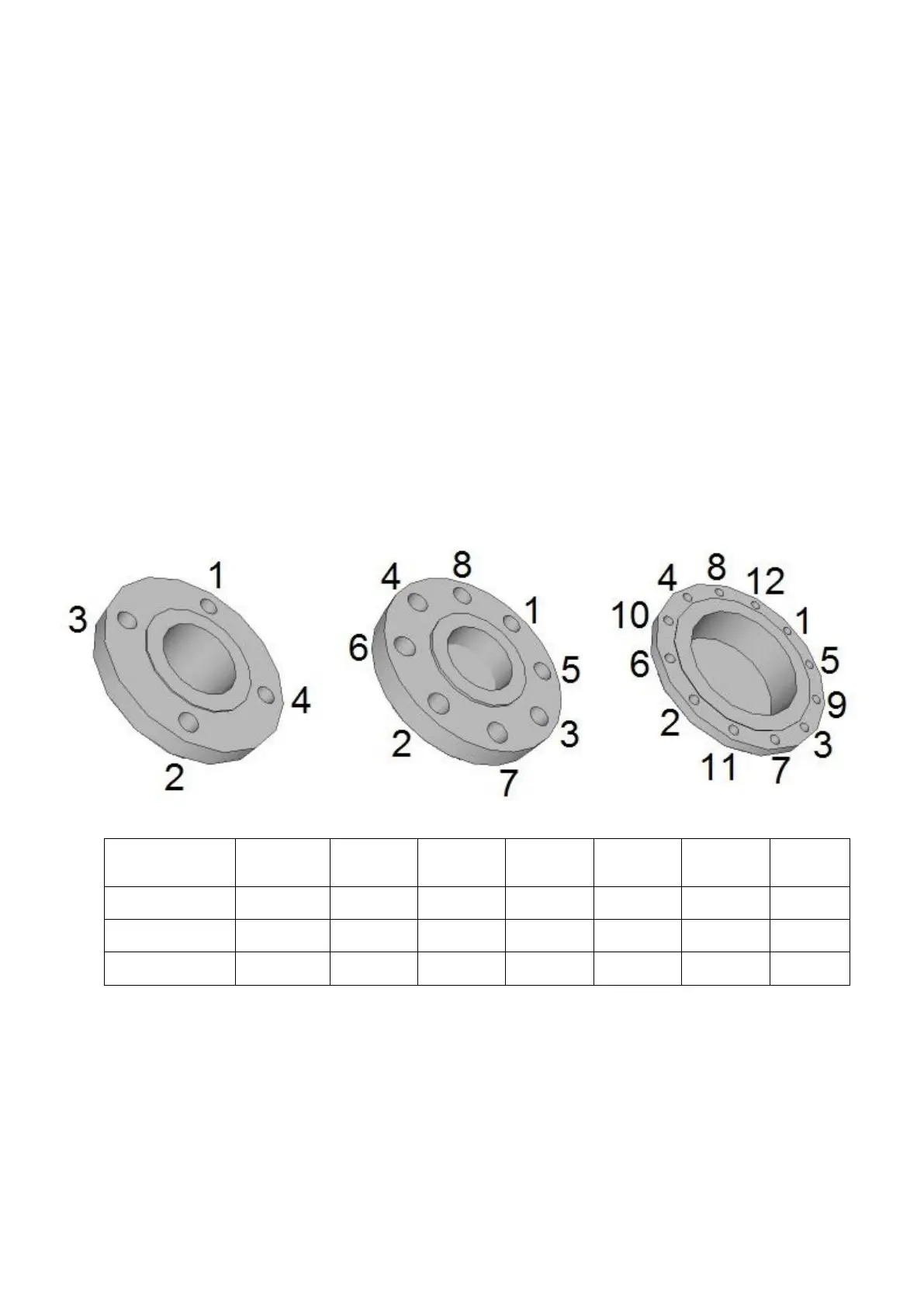

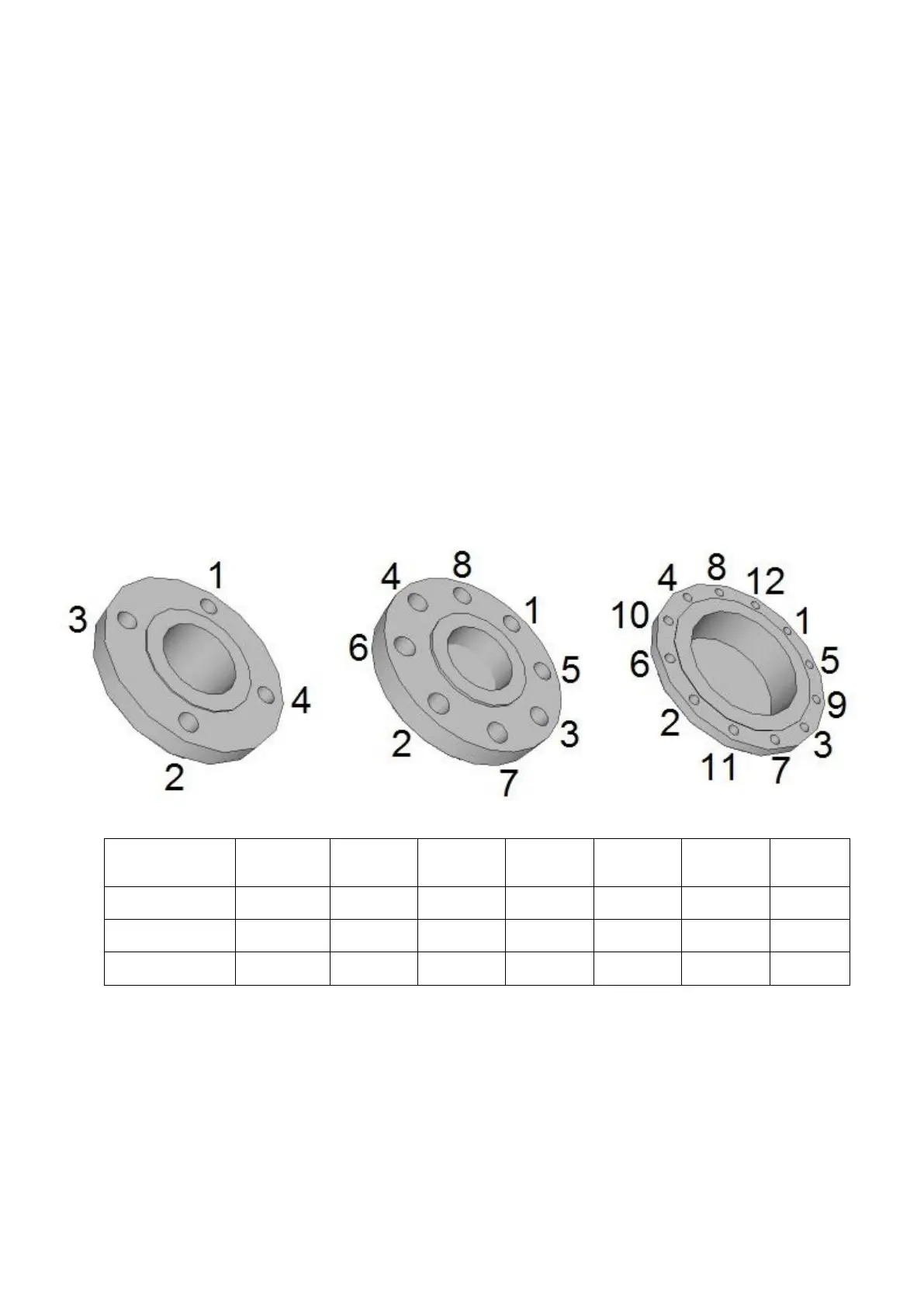

It is absolutely essential to tighten the connecting bolts and nuts evenly and subsequently on

opposite sides and in the order illustrated in the figure with the maximum torque indicated in

the table below.

When the thermoplastic tube in flange construction is used, the same torque figures apply as

those for the corundum tube.

If you do not find your inside diameter or construction in the Torque table, it is a special or

non-standard construction. In this case contact the manufacturer for detailed information

please.

Loading...

Loading...