CALOR 40 Manual Page 8 (total 27) COMAC CAL s.r.o.

of these meters and flow meters in terms of this manual at the manufacturer. The

manufacturer will issue certificates, confirming that the workers have passed this training

course.

The inductive flow sensor is installed in arbitrary position in vertical piping. In the case of

horizontal piping, it is necessary to make sure that the sensor is installed with its measuring

electrodes in horizontal position. If the version with grounding electrode, or empty pipe test is

in question, then the installation is always carried out with a cable grommet for the sensor, or

with the evaluating unit in the upright position (in case of compact version). Then the

grounding electrode is in the bottom position and the sensing electrode in the top position of

the flow sensor.

The assembly is carried out by fixing between the counter-flanges (sandwich) that are welded

to the modulating piping (5d before and 3d behind in the flow direction) whereas the fluid

must flow through the flow sensor in the direction that is indicated with an arrow on it.

When counter flanges are being welded on the pipe, it is essential to maintain their alignment

so as to ensure uniformity of seating faces of the flanges on the face areas of the sensor

(however, this must not be reached by uneven tightening of the connecting bolts because there

is a risk of leakage resulting from temperature strain in the future and, in some case, the

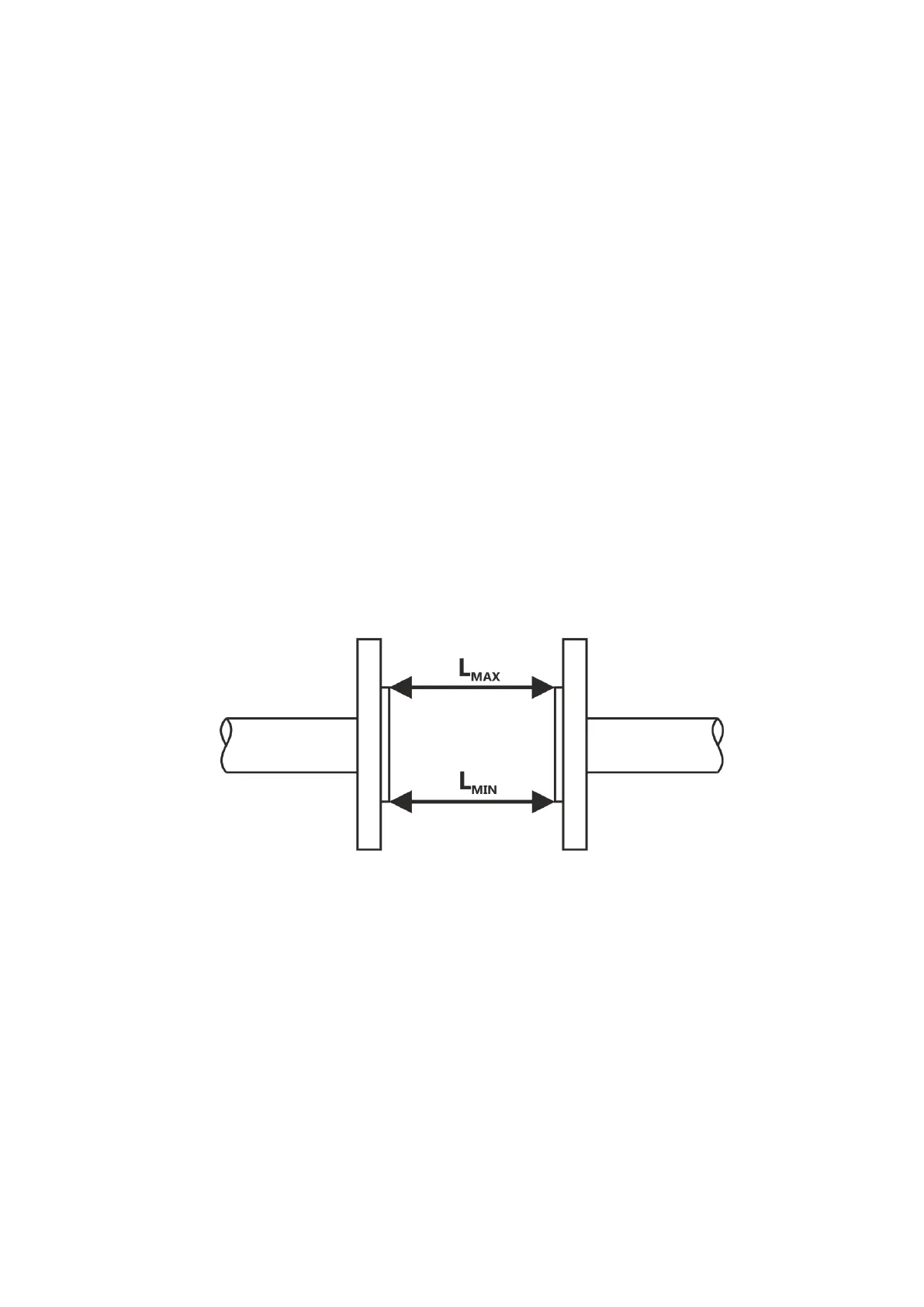

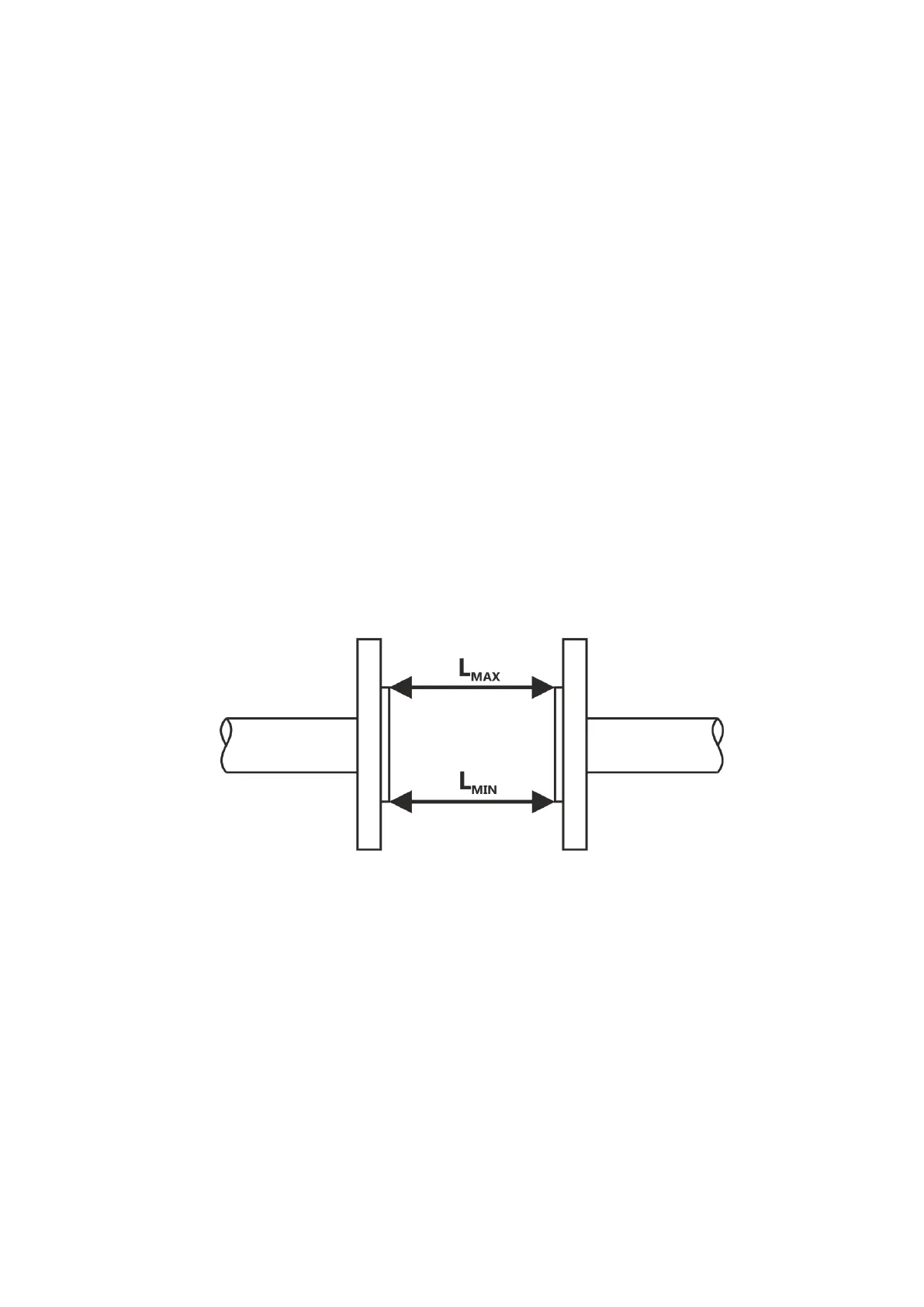

measuring tube might crack when being tightened unevenly). The difference in L

MAX

and

L

MIN

distances of the both sealing faces on the flanges before the flow sensor is installed,

must not be longer than 0.5 mm.

In the same way, the mating positions of holes for connecting bolts in counter-flanges should

be ensured as well as ample room behind the flanges for the connecting bolts and nuts in order

to ensure proper installation of the sensor in the pipe and the attachment by connecting bolts.

The manufacturer recommends using a fitting adapter for welding. It is absolutely

inadmissible to use the flow meter as a fitting adapter due to possible thermal destruction. The

welding current must not flow through the flow sensor during electric welding. The

installation of the flow sensor itself is carried out after all welding, painting, building, and

similar jobs are finished.

If the flow sensor has a fibre-rubber sealing, it is inevitable to lubricate it using graphite

grease or oil with graphite.

Loading...

Loading...