CALOR 40 Manual Page 7 (total 27) COMAC CAL s.r.o.

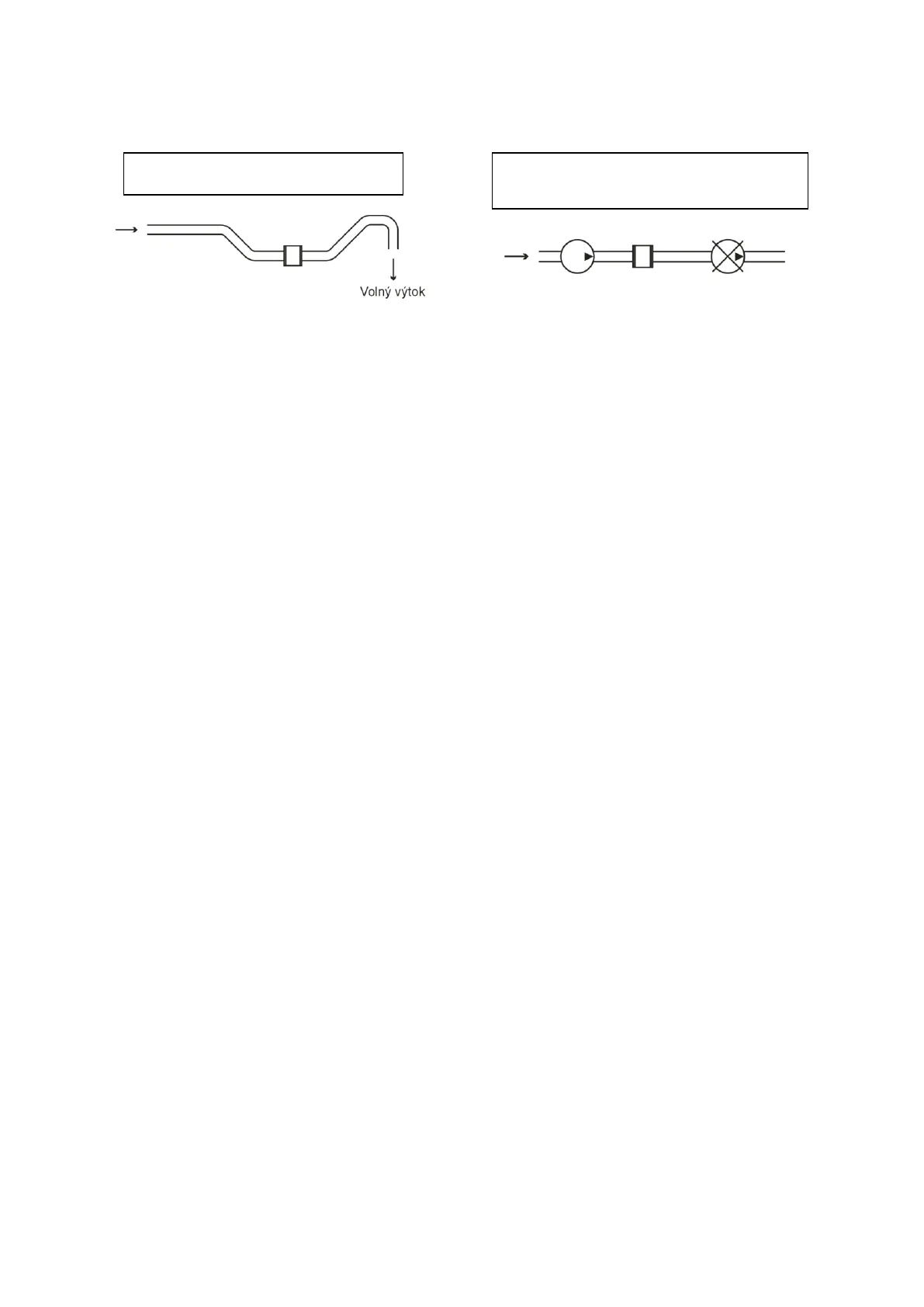

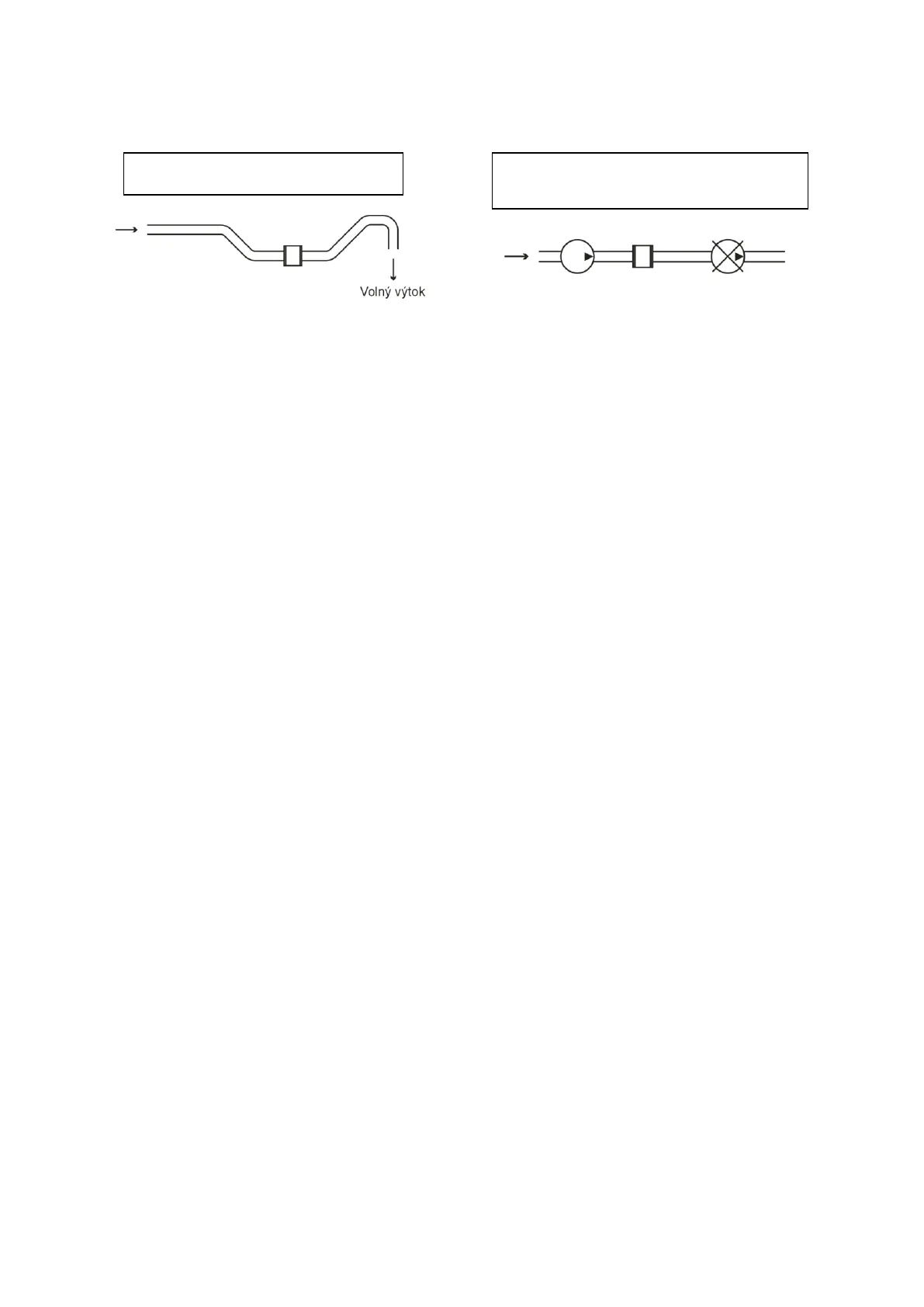

Free inlet or outlet Pumps

The flow of liquid in the flow sensor

The flow of liquid in the flow sensor should be steady and with no whirls. For this reason,

straight pipe sections of the same diameter as that of the sensor (permitted deviation +5%)

are usually inserted before and behind the flow sensor. The minimum length of the sections is

3d before the flow sensor and 2d behind the flow sensor.

It is not necessary to adhere to the minimum length of the straight section when conical

junctions with angles

1

,

2

16 (

1 –

angle of the cone before the flow meter, 2

–

angle of

the cone after the flow meter) are used if their minimum internal diameter is identical to the

internal diameter of the flow sensor (with permissible deviation +5%).

No sources disturbing the steady flow must be found in the specified straight sections. They

must be positioned in the pipe behind the flow sensor or at the longest possible distance

before it.

The sources of disturbance may substantially decrease the measuring range and accuracy of

the flow meters.

Recommendation

When the flow is whirled up, increase the stabilizing sections of the pipe or install the flow

conditioner.

When mixtures are blended, it is necessary to install the flow meter either before the blending

spot or at a sufficient distance behind it (30xd min.) otherwise it may result in unstable

readouts.

The grounding rings are necessary when plastic or metal pipes with the internal non-

conductive layer are used.

Compact construction of the meter:

When the compact heat meter or flow meter is used, it is necessary to respect the maximum

temperature of liquid up to 90 °C. If this temperature is exceeded, correct operation of the

Electronic Evaluation Unit is not secured, eventually there is a risk of its destruction.

Do not pick up the meter during installation by means of the Evaluation Unit housing.

If the pipe is exposed to excessive vibrations (e.g. from pumps), the use of compact meters is

not recommended.

The designer, or in some case, the user himself are responsible for suitability and adequacy of

application of compact inductive meters.

Actual in-pipe installation

The flow meter is installed and put in operation only by the organization with authorization to

conduct such activity and whose staff has passed the appropriate training course in installation

The flow meter must not be installed

in the suction side of the pump

Loading...

Loading...