CALOR 40 Manual Page 6 (total 27) COMAC CAL s.r.o.

of pressure. Therefore, the control butterfly valves and similar components should be inserted

behind the flow sensor. For the same reason, the flow sensor should not be installed at the

suction side of the pump. To prevent the bubbles from accumulating in the flow sensor while

the flow is slow, it is useful for the pipeline either to be slightly ascending or the sensor is put

into the vertical part of the pipeline.

If the meter is populated with measuring electrodes only (2 or 3 electrodes located beyond

the upper profile of the tube), it is necessary for proper function of the meter, to fill up the

flow sensor with the fluid to be measured so that erroneous measurement of quantity of liquid

passing through the meter can be avoided when the pipe is empty. It is necessary to select the

location of the meter in such a way that the flow sensor aeration is avoided.

In the case of an open system, the flow sensor is placed in the bottom position of the U-

profile, ensuring that the fluid will not flow out of the sensor.

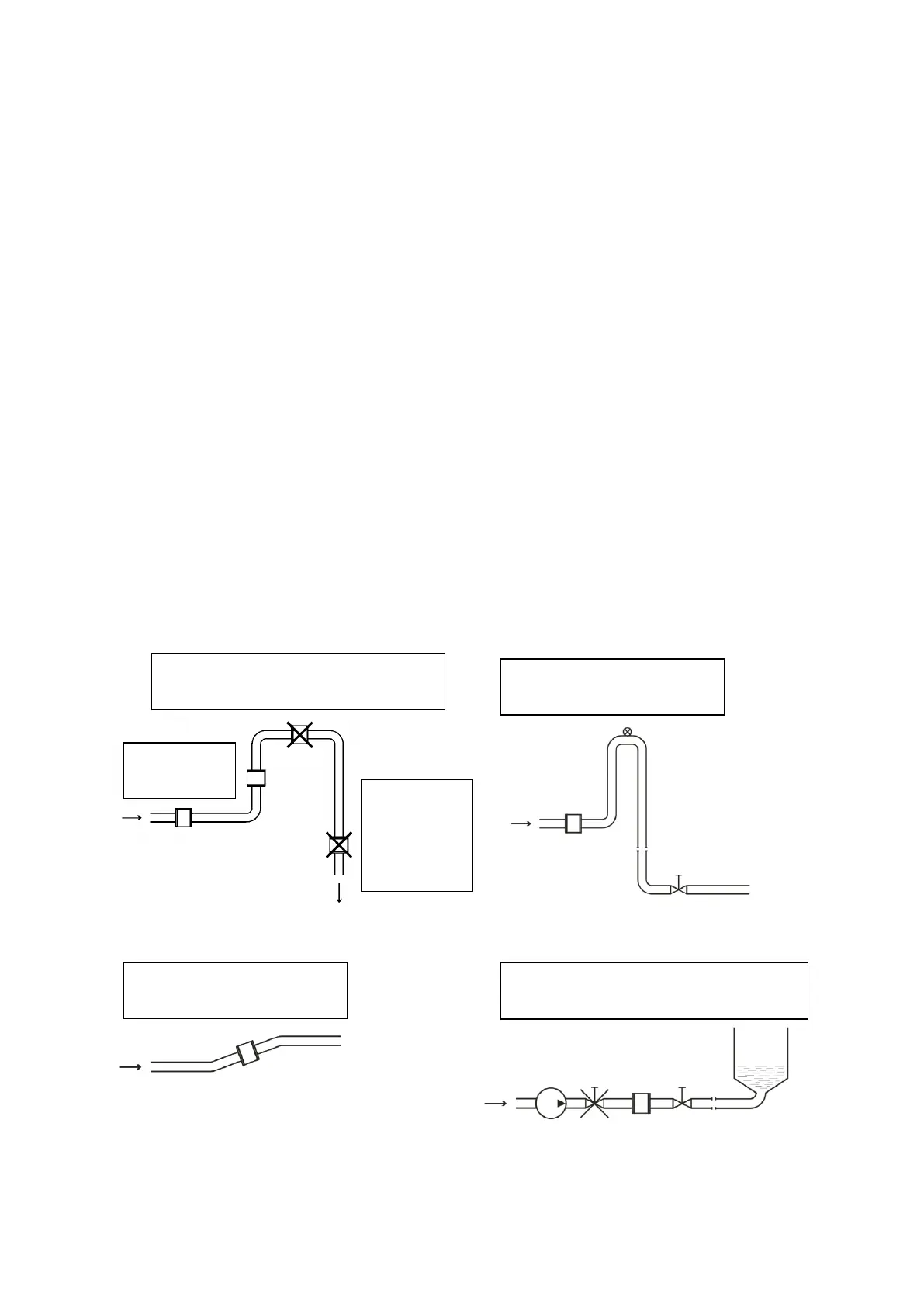

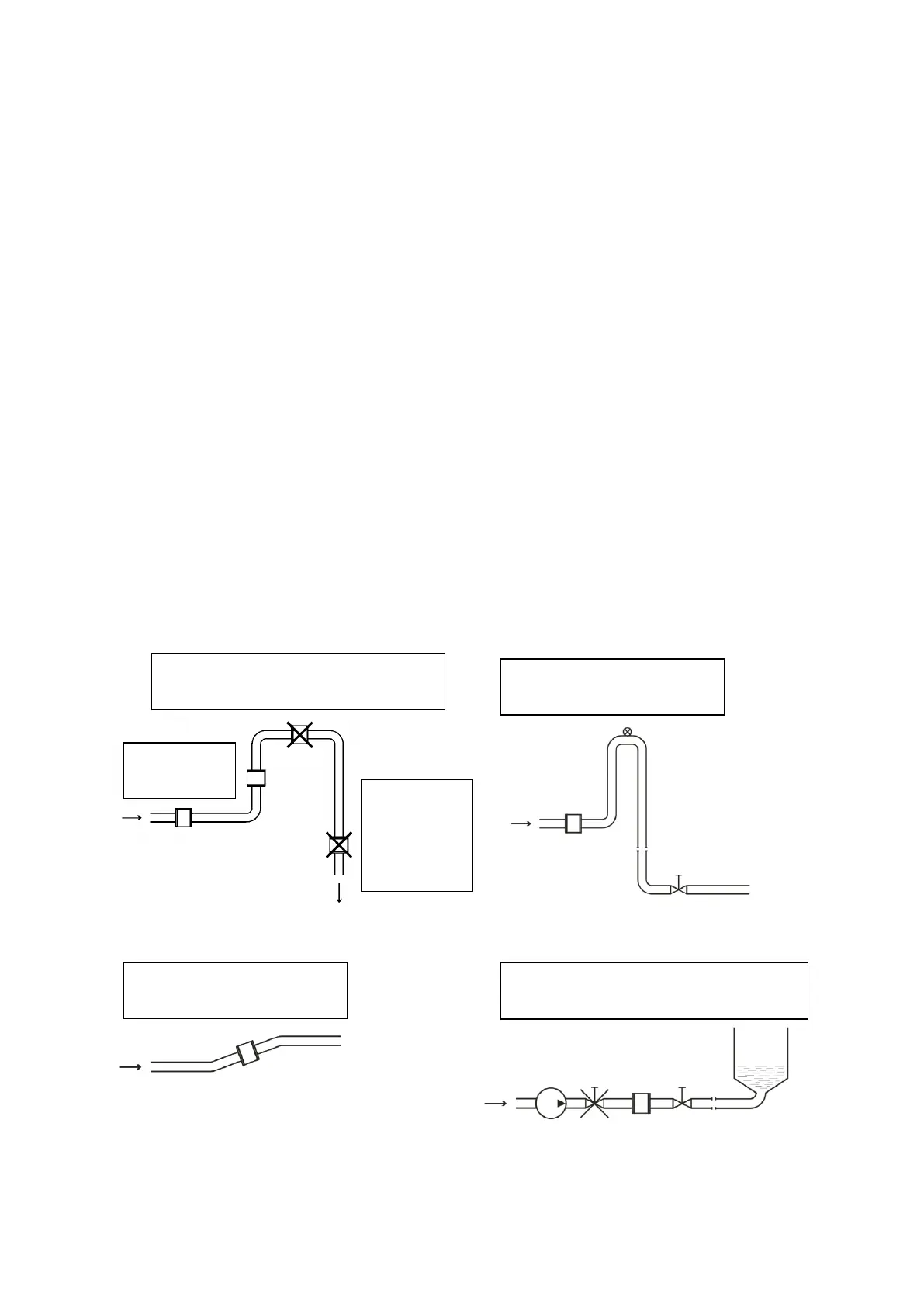

Examples of installation

The trouble free and accurate operation of the meter depends on correct location in the

system, especially when the internal PTFE or rubber lining is used where there is a risk of

damage as a result of negative pressure. The most frequent methods of positioning are

illustrated in the following figures:

Recommended positions for installation Down pipe

Horizontally positioned pipe Long pipe

(bubbles are accumulated in the

pipe; erroneous measurement)

Install a purge valve

behind the sensor

Place the sensor into a

slightly ascending pipe

Pipe is

empty;

erroneous

measuring

Always install the control and shut-

off components behind the sensor

Loading...

Loading...