MicroBlaster MB1000 Section 3: Using the MicroBlaster

Comco Inc. 3-5 Issue Date: July 2016

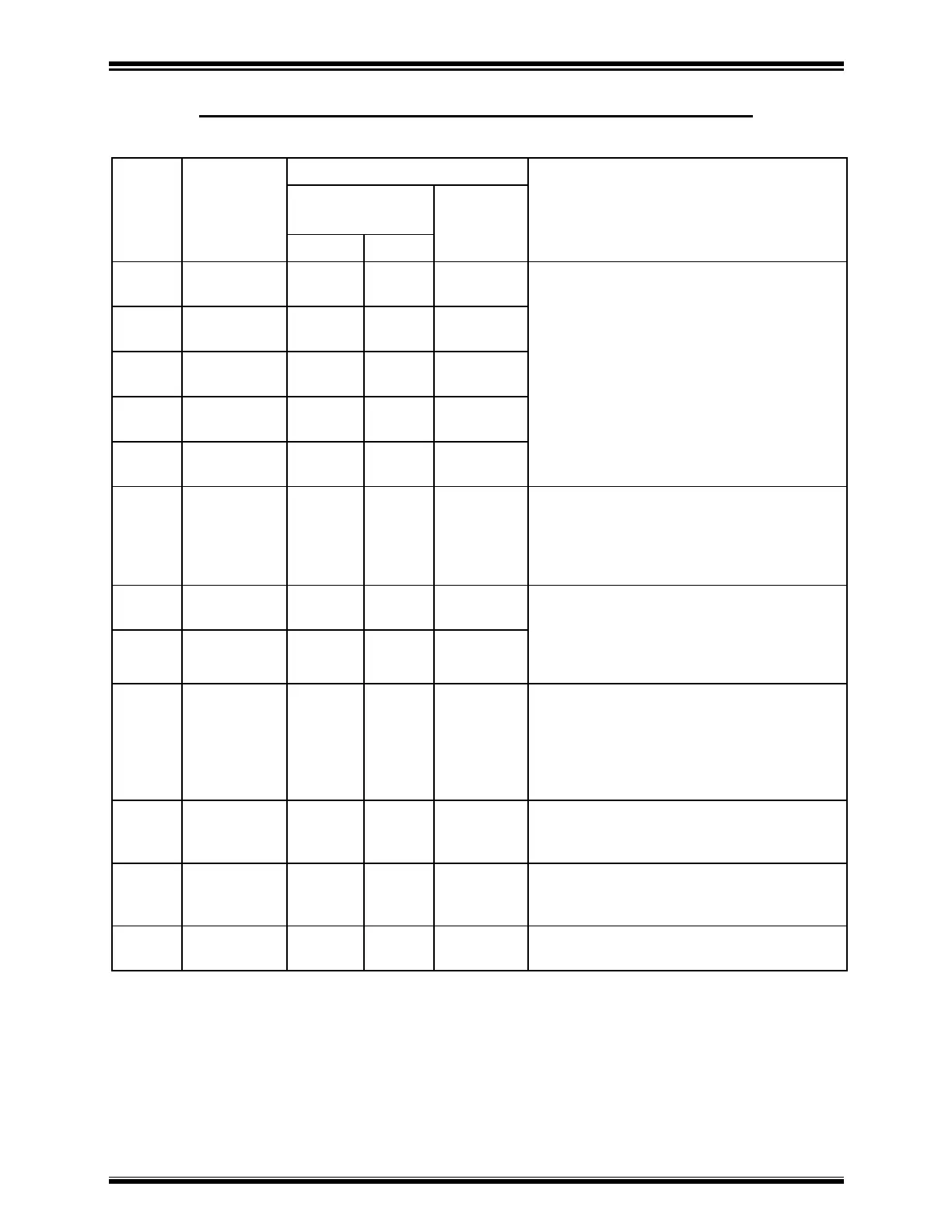

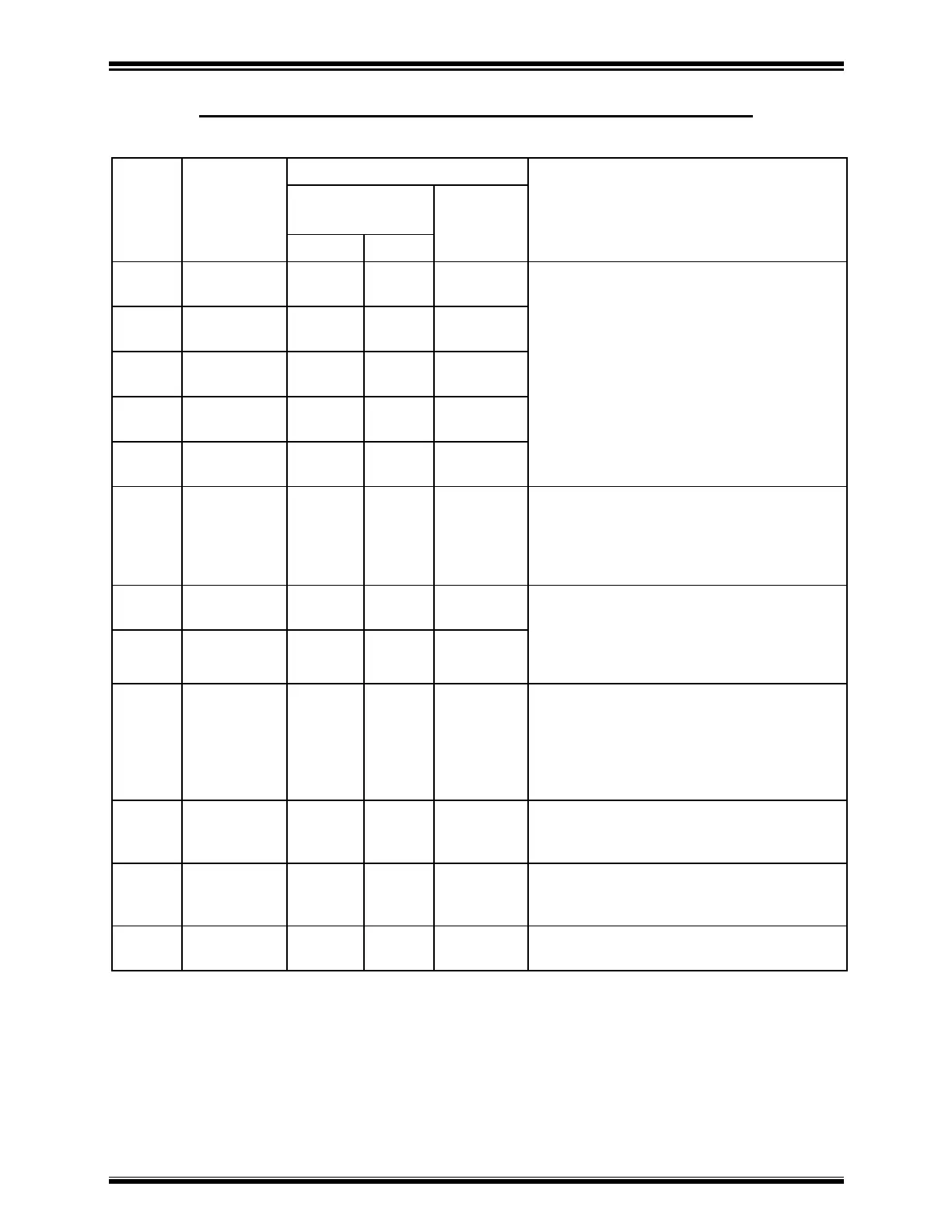

Table 3-2: Common Abrasives and Their Applications

Description/Characteristics

The most common abrasive used. A very

hard abrasive that cuts well through almost

any material, particularly brittle ones.

Normally leaves a matte finish, with the

surface roughness being dependent upon

the abrasive size and the blast pressure.

Somewhat sensitive to moisture.

Good for light deburring and satin finishing

of some metals but not good for cutting.

Can be used to remove loose surface

particles such as oxides. Sensitive to

moisture.

The fastest cutting of the standard

abrasives. The best abrasive to deburr

stainless steel and titanium parts. Does not

absorb moisture. Dark gray or black in

color.

A very gentle abrasive, good for very light

cutting of soft materials. Can be used to

remove conformal coating from PCBs.

Water soluble and easily removed from

delicate parts. Susceptible to moisture and

cannot be heated to above +150ºF.

Gentle abrasive that can clean metal or

ceramic surfaces without changing the

surface finish. Absorbs moisture easily.

Good for stripping soft materials, such as

paint or conformal coating, from harder

substrates.

For light cutting of soft to medium materials.

NOTE: Always start the work shift with fresh abrasive powder. Powder left sitting in an

un-pressurized machine overnight can absorb moisture. This contaminated

powder can cause flow problems. Keep powder containers sealed and stored in

a cool, dry place.

Loading...

Loading...