MicroBlaster MB1000 Section 4: Maintenance

Comco Inc. 4-3 Issue Date: July 2016

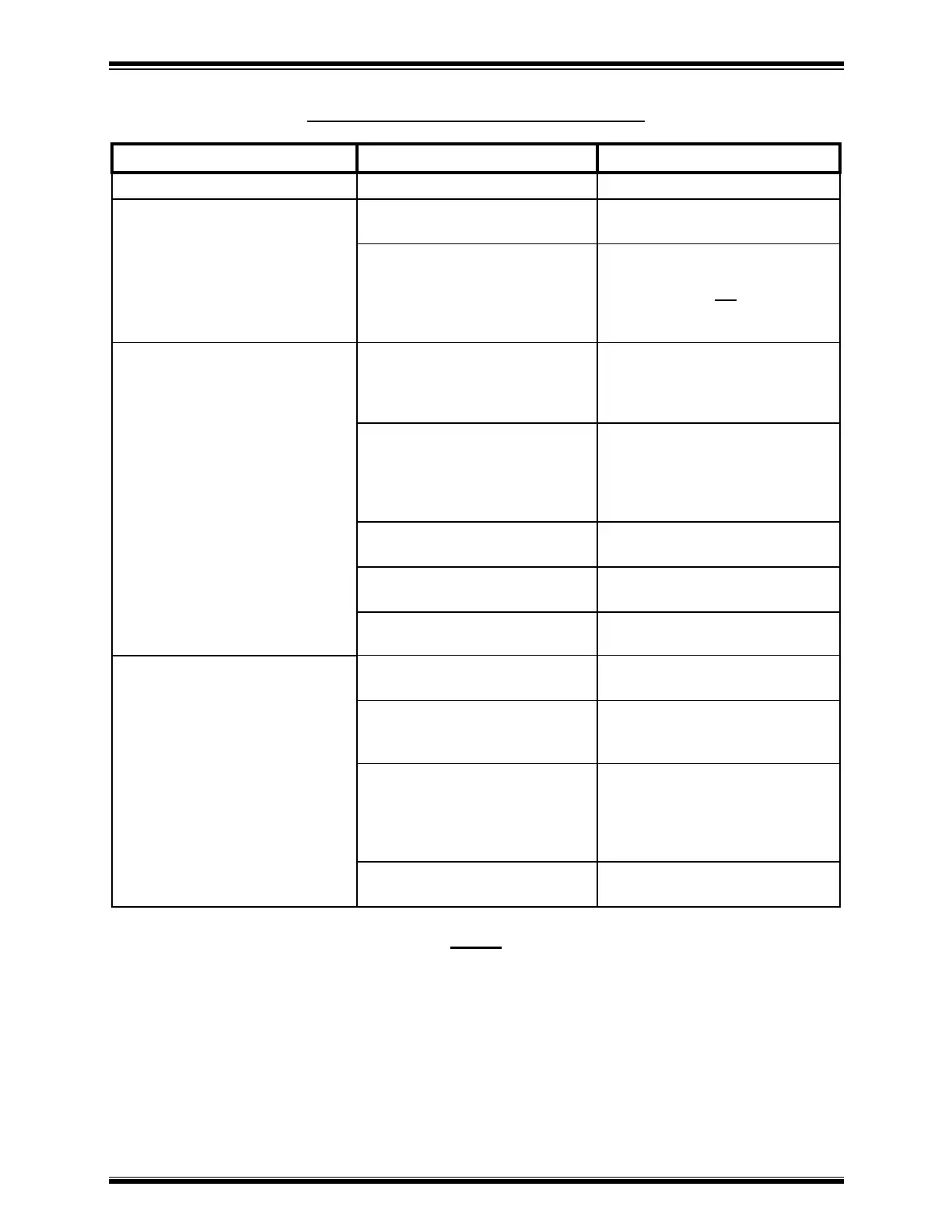

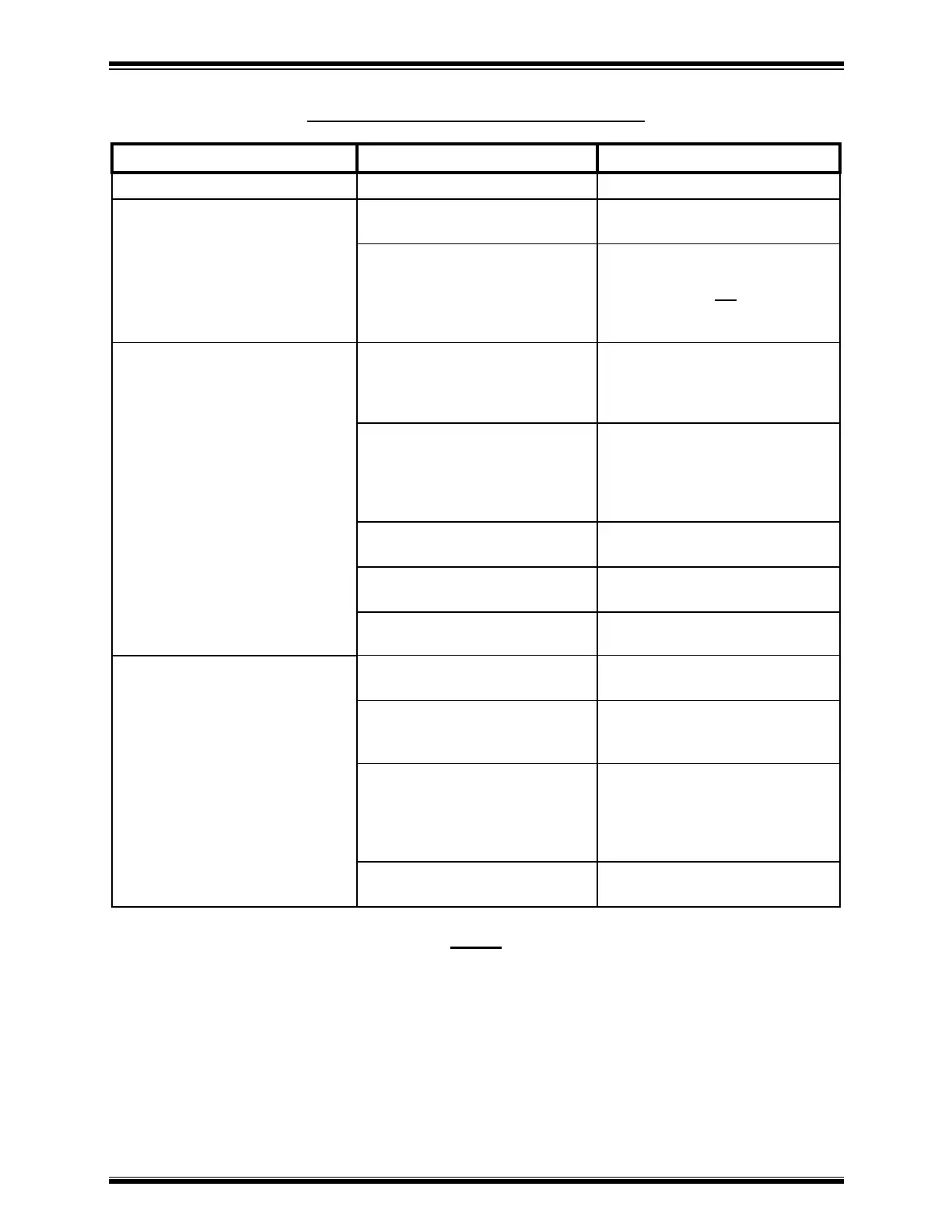

Table 4-1: Maintenance Intervals

Reposition hoses in pinches.

Inspect nozzle tips for wear.

Replace if necessary.

If the tank cover is removed

frequently to change abrasive,

lubricate with a dry lubricant

(see directions on following

pages).

Clean and lubricate (see

following pages). Inspect

O-rings and threads. Check for

leaks.

If the MicroBlaster is used

heavily, it may be necessary to

inspect the modulator for wear

on a monthly basis (see

directions on following pages).

Inspect the Handpiece Nose for

wear. Replace if necessary.

Inspect tank orifice for

excessive wear or clogging.

Service Air Dryer. Inspect

powder storage conditions.

Inspect the modulator for wear

(see directions in section 5).

Inspect hose connectors for

wear. Replace if necessary (see

description on following pages).

Inspect the power cord and

footswitch cable. Remove the

cover and check for internal

leaks (see description on

following pages).

Inspect pinch assemblies for

worn or inoperable parts.

NOTE

With an abrasive machine, wear to critical parts is inevitable. The MicroBlaster Tune-Up Kit

contains all the parts you need to conduct routine maintenance and keep an inventory of items

that you can replace yourself. Comco recommends that these parts be replaced annually, or

every 2000 hours of operation, whichever comes first. Establishing and following a regularly

scheduled maintenance program for your equipment, can reduce costly downtime. A well

maintained MicroBlaster delivers a more consistent powder flow, minimizes processing time,

and actually saves you money by reducing powder consumption. Contact Comco’s Customer

Service Department (see section 5, page 2) and order part number MB1440 to get a Tune-Up

Kit for your MicroBlaster today.

Loading...

Loading...