1.ThedierentlockingdevicesaccordingtoISO14119

Locking devices for dangerous machinery guards are subject to ISO 14119. There are three component

technologies:

2. Comparative technologies

Associated locking devices

for guards: ISO 14119

4

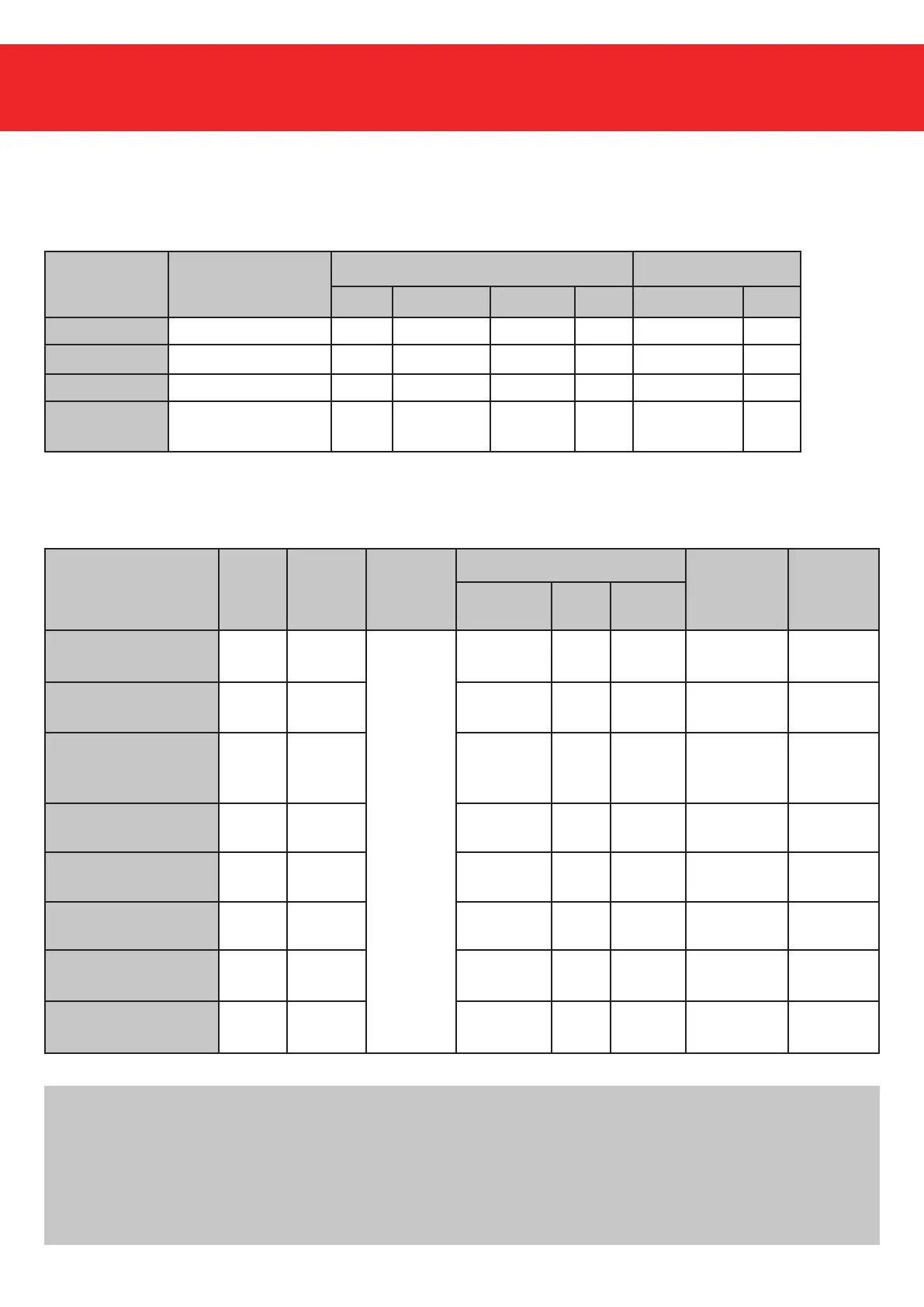

Product Type Level

of

coding

Method

of

mounting

Possibility of assembly Direct

control of

movement

Agro

compa-

tible

Summary Hid-

den

Em-

bedded

roller switch 1 None Tamper-

proof

screws

or

Remo-

vable

screw

No Yes No Yes No

hinge switch 1 none Yes Yes No Yes No

key switch 2 low Subject

to condi-

tions

No No Yes No

reed switch 3 or 4 low Yes Yes No No low to

high

ACOTOM process 4 low to

medium

Yes Yes Yes Yes high

induction sensor 3 low Yes No No Subject to

conditions

No

transponder sensor 4 low to

medium

Yes No No Subject to

conditions

No

RFID SENSOR 4 high Yes No No Subject to

conditions

No

Notes: The sensor equipped with the process ACOTOM3 is the only one that can be embedded in the

door and in the frame, even if the material is stainless steel or aluminum. This makes the sensor totally

invisible. Several forms of boxes are available, including an INOX M30 IP 69K version.

The sensor with the process ACOTOM which is the only one that has a magnetic hold up to 4 Kg: this

is the BOSTER.

Since 2006, some of our sensors have a screw cover for invisible mounting and additional protection.

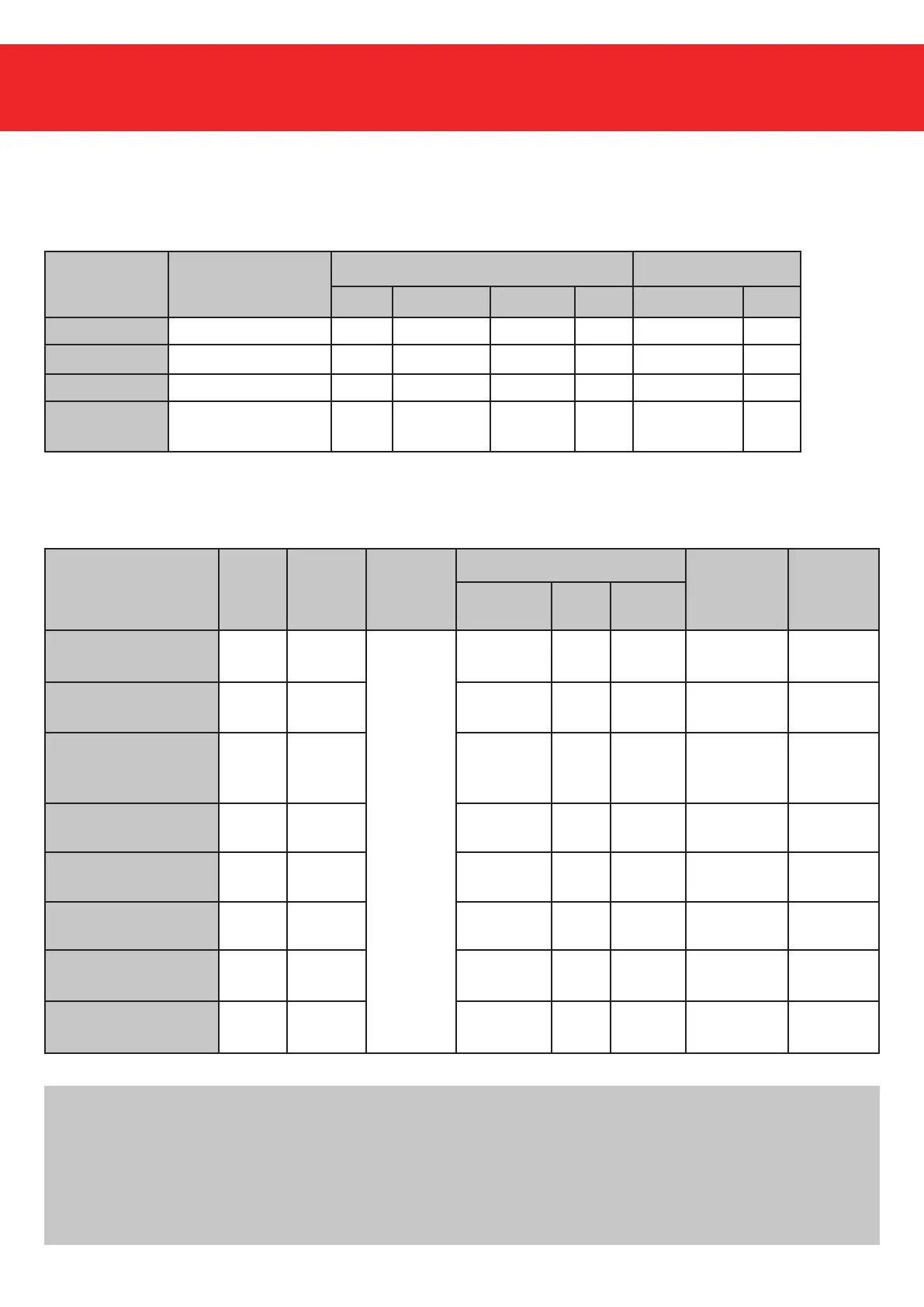

Technologies Device Power switch Sensor

Roller Hinge key Reed ACOTOM RFID

1 Mechanical X X X

2 Magnetic X X

3 Induction or RFID X

Standard

ISO 14119

Type 1 1 2 3

4

4 4

Loading...

Loading...