34

To install a new separator element, reverse

the above removal sequence. Make certain

the flange and cover surfaces are clean.

Make certain the element flange gaskets

have a grounding staple. Torque the separator

to flange capscrews evenly and securely to

44 ft. Lbs. Make certain, also, that the

separator drain tube touches the bottom of

the element. (Make a new tube, if

necessary).

For information concerning the conditions

which indicate a separator element is

defective refer to the service diagnosis chart,

Section VII.

DANGER

RECEIVER/RESERVOIR COVER

RETAINING STUDS AND NUTS ARE

SPECIAL. DO NOT SUBSTITUTE

COMMON BOLTS OR NUTS IN PLACE OF

THESE SPECIAL STUDS AND NUTS.

AIR END

The air end for these units is serviced only as

a complete assembly using a new or factory

rebuilt air end.

Parts available for field service include the

input shaft rotary oil seal and the fan drive

shaft rotary seal.

Rebuild kits are available for air ends

exceeding the warranty period.

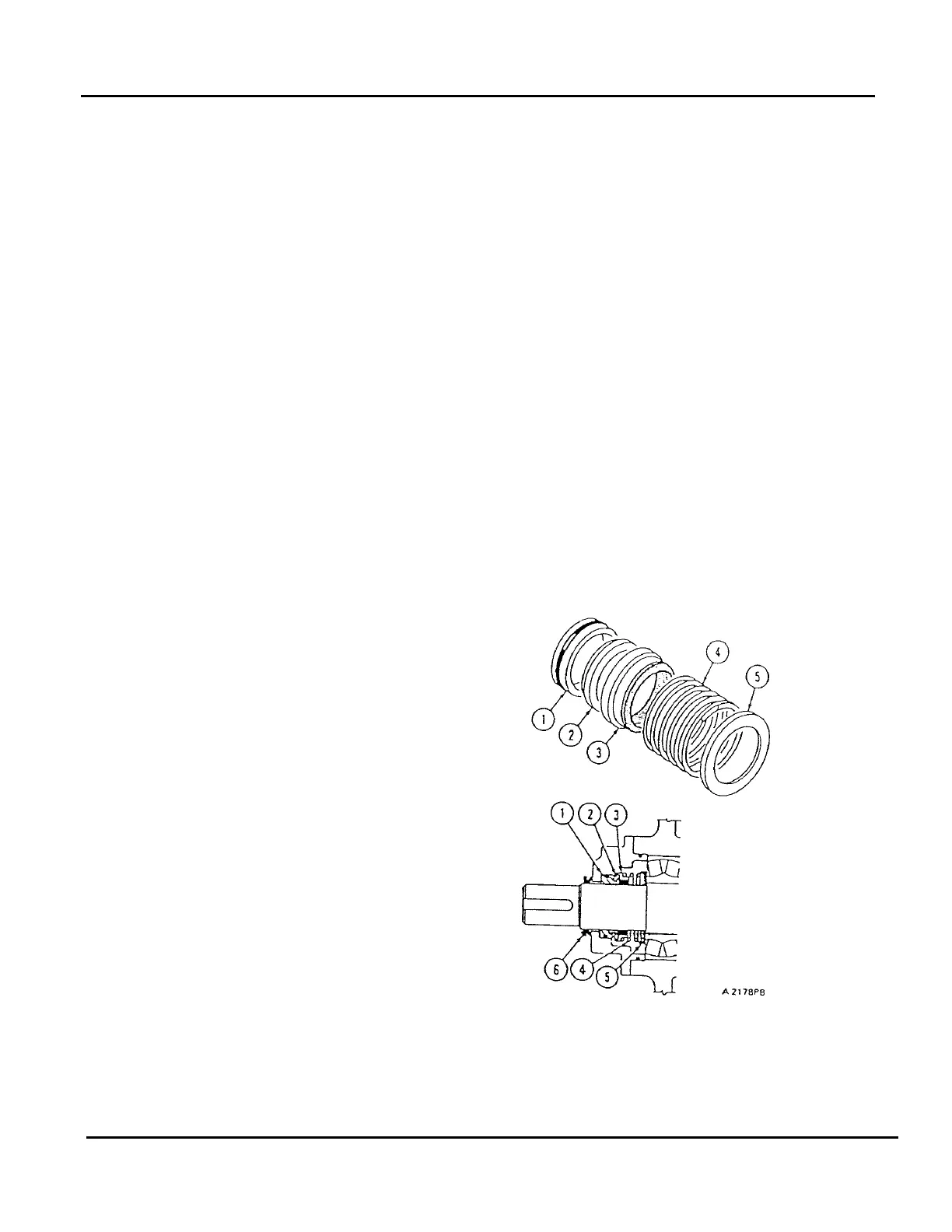

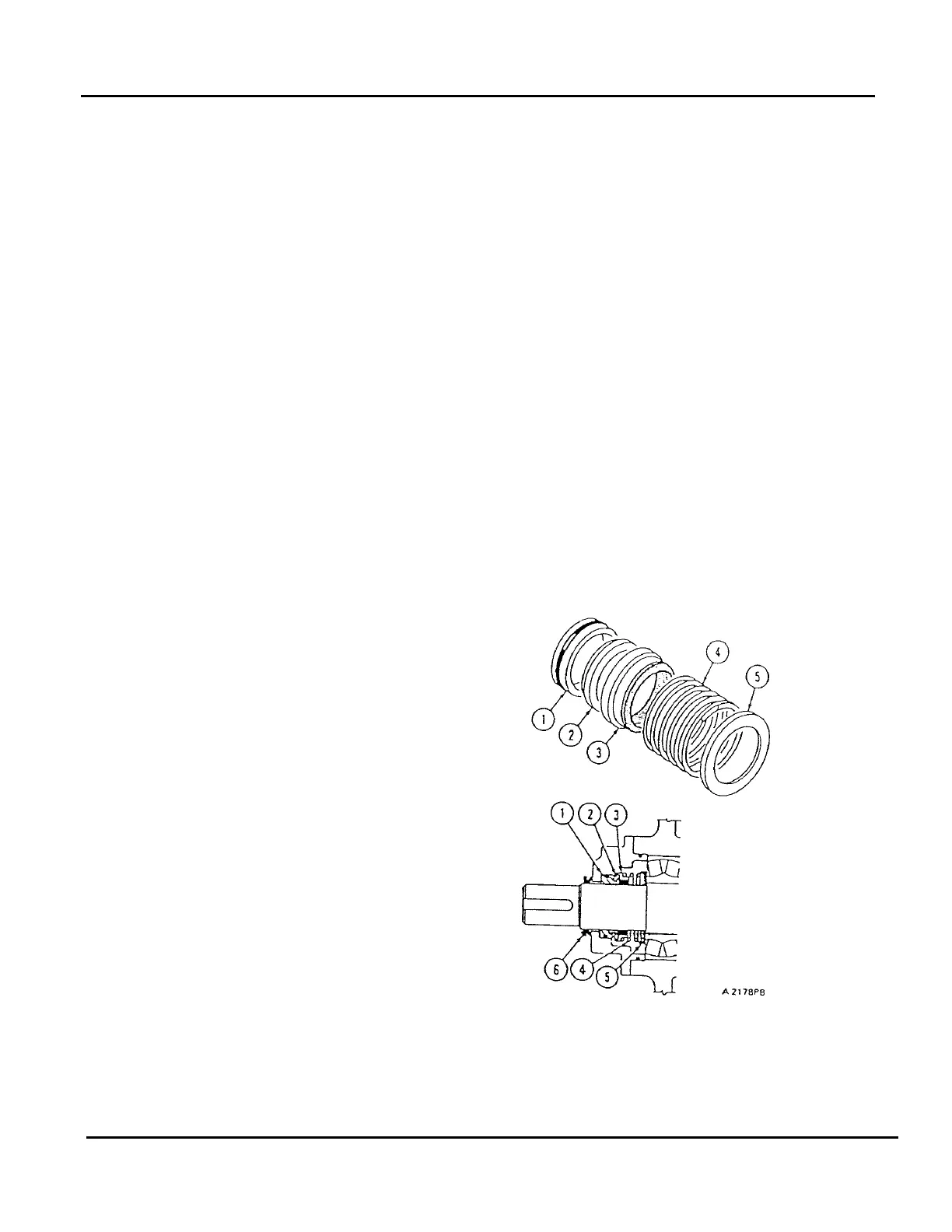

AIR END INPUT SHAFT OIL SEAL

REPLACEMENT (Figure 14)

To replace a rotary seal, proceed as follows:

1. Loosen rocker base spring retainer and

rotate motor toward the compressor to

relieve drive belt tension.

2. Remove the compressor input shaft

drive pulley. Remove belt guard and

disconnect oil lines.

3. Remove the seal retainer (front cover) to

front retainer attaching capscrews and

remove the cover with outer seal.

Discard outer seal.

4. Remove the oil seal assembly, including

the spring and spring guide, from the

input shaft.

5. Remove the oil seal face insert, with o-

ring seal, from the seal retainer. Discard

the face insert, with o-ring seal.

6. Thoroughly clean all remaining parts.

Make certain all gasket material is

removed from the seal cover and front

retainer mating surfaces.

7. Lubricate the new seal face insert with

clean compressor oil and install the

insert in the seal retainer.

8. Lubricate the rotary seal assembly with

clean compressor oil, including the

carbon ring, and install the seal spring

guide, spring, and seal assembly on the

input shaft.

CAUTION

BE CAREFUL NOT TO SCRATCH THE

SEAL FACE INSERT OR SCRATCH OR

BREAK THE CARBON RING OR THE SEAL

ASSEMBLY. WIPE THE LAPPED

(MATING) SURFACES OF THE SEAL

INSERT AND CARBON RING WITH A

CLEAN LINT FREE CLOTH BEFORE

INSTALLING THE SEAL RETAINER.

FIGURE 14

AIR END INPUT & FAN SHAFT OIL SEAL

1. Seal Face Insert

2. Carbon Ring

Loading...

Loading...